Distillation Columns

Exploring the Science and Technology Behind it Have you ever wondered how the beverages you enjoy are made? Or how the chemicals used in various industries are produced with such precision? The answer lies in the fascinating world of distillation columns.

These towering structures play a crucial role in separating and purifying liquids, providing the foundation for countless products we encounter every day. In this article, we will delve into the science and technology behind distillation columns. How they contribute to the separation of different components in a mixture. Discover the various types of distillation columns and their applications in industries such as petroleum, chemical, and pharmaceutical. From the fundamental principles to the latest advancements, we will help you gain a comprehensive understanding of this essential technology.

The principles of distillation

Distillation is a fundamental separation process that capitalizes on the varying boiling points of substances within a mixture to achieve separation. This technique leverages the fundamental principle that, upon heating, the component with the lower boiling point will evaporate first, leaving the higher boiling point component behind. The underlying concept here is the establishment of vapor-liquid equilibrium.

In the distillation column, the mixture is subjected to heat at its base. As the heat is applied, the vapors ascend within the column, encountering a succession of trays or packing materials. These trays or packing materials offer a substantial surface area for the vapors to condense and interact with the liquid phase, enabling mass transfer between the vapor and liquid. The condensed liquid then descends through the column, perpetuating the process until the desired separation is attained.

Distillation is a versatile technique that can be implemented in both batch and continuous operations. In batch distillation, a fixed volume of the mixture is heated and separated sequentially, whereas continuous distillation involves a steady influx of the mixture into the column with concurrent withdrawal of the separated components. This flexibility makes distillation an essential process in various industries for the separation and purification of diverse mixtures.

Types of distillation columns

There are several types of distillation columns, each serving specific purposes. Understanding these types is essential for efficient chemical processing and refining operations. Here are some common types of distillation columns:

- Fractionating Column: Fractionating columns, also known as fractional distillation columns, are the most common type. They are utilized to separate mixtures of liquids with different boiling points, such as crude oil in a refinery. The column features multiple trays or packing materials, facilitating the separation of components as they vaporize and condense at different heights within the column.

- Reactive Distillation Column: Reactive distillation combines distillation and chemical reactions within a single column. This type is employed when the desired product can be obtained through chemical reactions that occur during the distillation process. It’s an efficient way to produce specific chemical compounds while separating them from the mixture.

- Azeotropic Distillation Column: Azeotropic distillation is used to separate azeotropic mixtures – substances that form constant boiling mixtures. In this column, a solvent or entrainer is added to break the azeotrope, allowing for the separation of components that would otherwise boil together.

- Steam Distillation Column: Steam distillation is commonly employed to extract essential oils from botanical materials. It uses steam to vaporize volatile compounds at lower temperatures, preserving their integrity. The vapor is then condensed to recover the essential oil.

- Batch Distillation Column: Batch distillation is a discontinuous process, often used for small-scale production or in research applications. Unlike continuous columns, it operates in batches, making it suitable for processes where changing feed compositions are common.

- Vacuum Distillation Column: Vacuum distillation is utilized when substances are sensitive to high temperatures or when the desired products have high boiling points. Operating under reduced pressure lowers the boiling points of components, making separation more feasible.

- Simple Distillation Column: Simple distillation is a basic form of distillation, mainly used for purifying and separating substances with significantly different boiling points. It’s not suitable for mixtures with close boiling points.

Understanding the nuances and applications of these distillation column types is crucial for optimizing chemical processes, ensuring product quality, and achieving energy efficiency in various industrial applications.

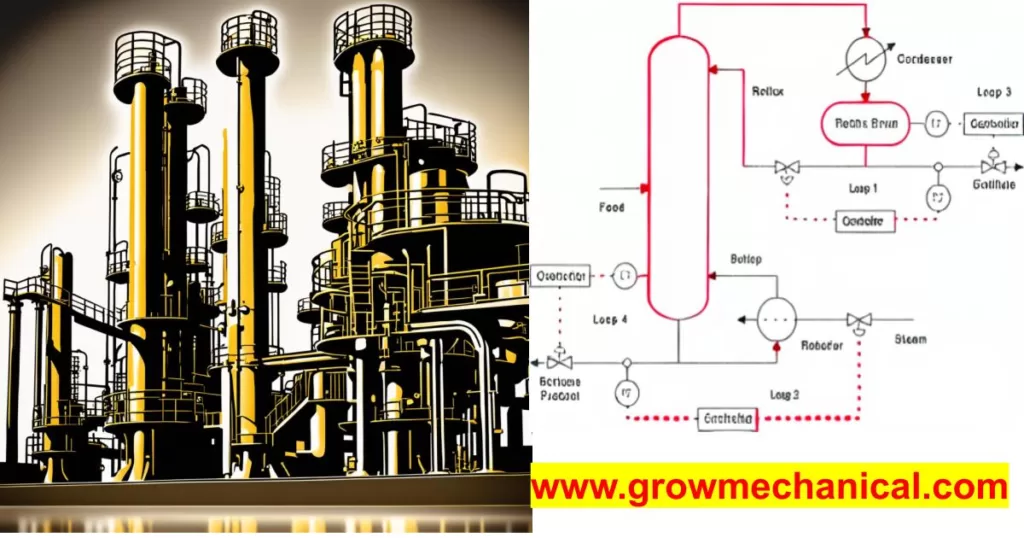

Components of a distillation column

A distillation column consists of several components that work together to ensure efficient separation. These components include:

Column Shell:

The column shell is the main cylindrical structure that holds all the internal components. It is usually made of steel and designed to withstand the high pressures and temperatures encountered during the distillation process.

Trays or Packing:

Trays or packing are used to increase the surface area for vapor-liquid contact. Trays are perforated plates that allow the vapor to pass through while capturing the liquid, while packing is a material that provides a large surface area for the vapor-liquid interaction.

Reflux Drum:

The reflux drum is a vessel located at the top of the column. It collects the condensed liquid from the top of the column and returns it as reflux to the column. The reflux helps to improve the separation efficiency and control the composition of the overhead product.

Condenser:

The condenser is responsible for cooling the vapors from the top of the column and condensing them back into liquid form. It uses a coolant, such as water, to remove heat from the vapors and facilitate condensation.

Reboiler:

The reboiler is located at the bottom of the column and provides the heat necessary to vaporize the liquid feed. It can be a steam-heated reboiler, a fired heater, or an electric heater, depending on the specific requirements of the process.

The distillation process

The distillation process consists of several steps that work together to achieve the separation of components. These steps include:

- Vaporization: The liquid feed is heated to its boiling point in the reboiler, causing it to vaporize. The vapors rise through the column, carrying the volatile components with them.

- Condensation: As the vapors rise through the column, they come into contact with the cooler surfaces of the trays or packing material. This causes the vapors to condense back into liquid form, releasing heat in the process.

- Mass Transfer: The condensed liquid flows down the column, and as it does, it comes into contact with the rising vapors. This allows for mass transfer between the vapor and liquid phases, facilitating the separation of components.

- Separation: The components with lower boiling points will vaporize and rise to the top of the column, while the components with higher boiling points will remain in the liquid phase and flow down the column. This separation is achieved by controlling the temperature and pressure within the column.

- Product Withdrawal: The separated components are withdrawn from the column at specific points, depending on their desired purity and concentration. The overhead product, which is the lightest component, is withdrawn from the top of the column, while the heavier components are withdrawn from lower trays.

Factors affecting distillation column performance

Several factors can affect the performance of a distillation column, including:

- Feed Composition: The composition of the feed mixture can significantly impact the separation efficiency of the column. A mixture with a large difference in boiling points between its components will be easier to separate than a mixture with components that have similar boiling points.

- Operating Pressure: The pressure within the column affects the boiling points of the components and the efficiency of the separation. By adjusting the pressure, it is possible to achieve better separation and control the composition of the overhead and bottom products.

- Heat Input: The amount of heat supplied to the reboiler affects the rate of vaporization and the separation efficiency. Insufficient heat input can lead to poor separation, while excessive heat input can cause flooding or carryover of liquid into the overhead product.

- Tray or Packing Design: The design of the trays or packing material affects the efficiency of the mass transfer between the vapor and liquid phases. Factors such as tray spacing, hole size, and packing material surface area can all impact the separation performance.

Distillation column design considerations

When designing a distillation column, several considerations need to be taken into account to ensure optimal performance. These considerations include:

- Column Diameter: The diameter of the column affects the vapor and liquid flow rates and the residence time within the column. A smaller diameter column may lead to higher pressure drops, while a larger diameter column may require more energy to operate.

- Tray or Packing Selection: The choice of trays or packing material depends on the specific separation requirements and the properties of the mixture being separated. Factors such as tray efficiency, pressure drop, and packing surface area need to be considered.

- Heat Transfer Area: Sufficient heat transfer area is required to ensure efficient vaporization and condensation. The heat transfer area can be increased by adding more trays or using a more efficient packing material.

- Control System: A well-designed control system is essential to maintain the desired separation performance. Temperature, pressure, and flow rate measurements are used to control various parameters within the column and optimize the separation process.

Applications of distillation columns

Distillation columns have a wide range of applications in industries such as petroleum, chemical, and pharmaceutical. Some common applications include:

- Petroleum Refining: Distillation columns are used in petroleum refineries to separate crude oil into various fractions, such as gasoline, diesel, and jet fuel. The different fractions have different boiling points and can be separated using different distillation columns.

- Chemical Production: Distillation columns are used in the production of various chemicals, such as ethanol, methanol, and ethylene. These columns help to purify the chemicals and separate them from impurities and by-products.

- Pharmaceutical Manufacturing: Distillation columns are used in the production of pharmaceutical drugs, where they help to separate and purify the active ingredients from the reaction mixture. They are also used to remove solvents and impurities from the final drug product.

- Food and Beverage Industry: Distillation columns are used in the production of alcoholic beverages, such as whiskey, vodka, and rum. They help to separate the alcohol from the fermentation mixture and achieve the desired alcohol content.

Advancements in distillation column technology

Over the years, there have been several advancements in distillation column technology aimed at improving efficiency and reducing energy consumption. Some of these advancements include:

- Structured Packing: Structured packing materials, such as corrugated sheets or wire gauze, offer increased surface area and improved mass transfer efficiency compared to traditional random packing. They allow for better separation performance while reducing pressure drops.

- Heat Integration: Heat integration involves optimizing the heat transfer between different stages of the distillation process. By utilizing waste heat or integrating the heating and cooling systems, energy consumption can be reduced significantly.

- Advanced Control Systems: Advanced control systems, such as model predictive control (MPC), allow for better control of the distillation process. They can optimize the column operation, minimize energy consumption, and ensure the desired separation performance.

- Reactive Distillation: Reactive distillation combines the separation and reaction steps into a single unit, offering improved yields and selectivity. This technology eliminates the need for separate reactors and reduces energy consumption.

Distillation column operation

It is an essential unit operation for the separation and purification of various chemicals and petrochemical products, including crude oil refining, chemical processing, and the production of fuels, solvents, and various chemicals.

- Introduction of Feed: The process begins with the introduction of a liquid mixture, often called the feed, into the distillation column. The feed may come from a variety of sources, such as a reactor or storage tank.

- Vaporization in the Reboiler: At the bottom of the distillation column, there is a heat source known as the reboiler. The heat source vaporizes the liquid feed. This vaporization is the first step in separating the components in the feed mixture.

- Column Internals: Inside the distillation column, there are various internal components, including trays or packing materials, which serve to provide surface area for vapor-liquid contact. The choice between trays and packing depends on the specific separation requirements.

- Rising Vapor and Falling Liquid: As the vapor rises through the column, it comes into contact with the descending liquid. This vapor-liquid contact allows for the transfer of components between the vapor and liquid phases, with lighter components tending to move upwards, while heavier components stay in the liquid phase and move downwards.

- Fractionation: The column is equipped with several trays or a packing material that helps separate the components by their boiling points. The components with lower boiling points will rise to higher trays in the column, while those with higher boiling points will condense and flow back down.

- Condensation in the Condenser: Near the top of the column, there is a condenser that cools the vapor. This condensation forms a liquid product known as the distillate or overhead product. This product is typically the lighter and more volatile components of the feed mixture.

- Withdrawal of Distillate: The distillate product is collected and withdrawn from the column. It can be further processed or used as a desired product.

- Bottoms Product: At the bottom of the column, a heavy liquid product, often referred to as the bottoms product, is withdrawn. This product contains the heavier and less volatile components of the feed mixture.

- Reflux: In many distillation columns, a portion of the overhead product is returned to the column as reflux. This reflux is used to maintain temperature control and improve separation efficiency. It helps in providing additional liquid for vapor-liquid contact on the trays or packing.

- Control Systems: Various control systems, including temperature and pressure controls, are used to optimize the operation of the distillation column and ensure that the desired product purity is achieved.

Distillation columns come in various configurations, such as simple distillation columns, fractional distillation columns, and more complex columns with multiple sections, reboilers, and condensers. The specific design and operation of a distillation column depend on the desired separation, the properties of the feed mixture, and the industry in which it is used.

important formula Distillation column designs

There are several important design formulas and equations associated with distillation column design. These formulas are used to calculate various parameters and properties of the distillation process. Here are some of the key formulas:

- Reid Vapor Pressure (RVP):

- Formula: RVP = 0.06125 * T + 0.651

- Where:

- RVP is the Reid Vapor Pressure in psi (pounds per square inch).

- T is the temperature in degrees Fahrenheit.

- Boiling Point Elevation (BPE):

- Formula: BPE = ΔTb = Kb * x

- Where:

- BPE is the boiling point elevation in degrees Celsius.

- ΔTb is the change in boiling point.

- Kb is the boiling point elevation constant.

- x is the molality of the solute.

- Relative Volatility (α):

- Formula: α = (yA / xA) / (yB / xB)

- Where:

- α is the relative volatility.

- yA and xA are the vapor and liquid phase mole fractions of component A, respectively.

- yB and xB are the vapor and liquid phase mole fractions of component B, respectively.

- Vapor-Liquid Equilibrium (VLE) Equation (Raoult’s Law):

- Formula: P = xA * PA° + xB * PB°

- Where:

- P is the total pressure in the system.

- xA and xB are the mole fractions of components A and B in the liquid phase.

- PA° and PB° are the vapor pressures of pure components A and B at the same temperature.

- Material Balance Equation:

- Formula: ∑(L) = ∑(V) = F

- Where:

- ∑(L) is the total liquid flow rate leaving the column.

- ∑(V) is the total vapor flow rate leaving the column.

- F is the feed flow rate into the column.

- Energy Balance Equation:

- Formula: ∑(H_L) = ∑(H_V)

- Where:

- ∑(H_L) is the total enthalpy of the liquid leaving the column.

- ∑(H_V) is the total enthalpy of the vapor leaving the column.

- McCabe-Thiele Method (Number of Theoretical Trays):

- Formula: N = (log((xD – xB) / (xA – xB))) / (log(α))

- Where:

- N is the number of theoretical trays.

- xD is the mole fraction of the desired distillate.

- xB is the mole fraction of the bottoms product.

- xA is the mole fraction of the feed.

- α is the relative volatility.

These are some of the fundamental formulas used in the design and analysis of distillation columns. Depending on the specific design and requirements of the distillation process, additional equations and correlations may be used to determine column specifications, operating conditions, and separation efficiency.

Conclusion

Distillation columns are vital in the separation and purification of liquids in various industries. The principles of distillation, the different types of distillation columns, and the components involved all contribute to the efficient separation of components in a mixture. Factors such as feed composition, operating pressure, and heat input can affect the performance of a distillation column, while design considerations and advancements in technology continue to improve their efficiency.

By understanding the science and technology behind distillation columns, we gain insight into the processes that fuel our modern world. From the production of beverages to the manufacturing of chemicals and pharmaceuticals, distillation columns play a significant role in ensuring the quality and purity of the products we rely on every day. So, the next time you enjoy a refreshing drink or use a chemical product, remember the fascinating science and technology that make it all possible.