Centrifugal pump

It is a mechanical device that is used to transfer the fluid from one place to another place with the help of a rotating impeller. The rotating impeller converts kinetic energy to hydraulic energy with the help of pump casing. Centrifugal pumps work on the principle of centrifugal force. When the impeller starts rotating, it sucks the fluid from the impeller’s eye. It creates a centrifugal force which throws the fluid outward to pump casing where the speed of the fluid is very high. Due to speed, the kinetic energy converts to hydraulic energy (pressure energy). The centrifugal pump is driven by an electric motor or turbine.

Parts of the overhang centrifugal pump listed below

shaft, impeller, bearing, casing, mechanical seal, bearing isolator, bearing, impeller, lock nut, lock nut gasket, casing gasket, casing wearing impeller wearing, the coupling key, impeller key, shaft key, coupling hub, throat Bush, sleeves.

Types of centrifugal pumps

On the base of the stage, the centrifugal pump is divided into three types.

- Single-stage centrifugal pump

- Two-stage centrifugal pump

- multistage centrifugal pump

On the basis of the casing design, there are divided into three types

- Diffuser type

- Volute type

- Vertex type

On the base impeller section, there are two types

- Single section impeller

- Double suction impeller

On the basis of installation, there are two types of

- Vertically mounted

- Horizontal mounted

On the basis of impeller installation, there are three types

- Overhang type

- Between bearing

- Vertically suspended

Overhanging type pumps divided by API standard

- OH1 is foot mounted horizontal type in section OH2 pump and it is copper with flexible coupled.

- OH2 is single-stage, centerline mounted, horizontal type pumps.

- OH2 is vertical type, single-stage, separate bearing bracket, and bearing houses are integral with pump types pump.

- Oh4 it is a vertical inline, single stage, rigid coupling with integrated motor shaft.

- OH5 is vertical, single-stage, and close coupled with a motor.

Between bearing

- BB1 is horizontally split casing, two-stage bearing supported at both end types with flexible coupled and driven by the motor.

- BB2 centrifugal pump it’s radially split casing two-stage with both ends bearing supported rotating assembly mounted on the base plate and driving by the motor with flexible coupled.

- BB3 type axially split casing with multistage with both end bearing supported rotating assembling and pump is mounted on a based plate driven by the motor with a flexible coupling.

- BB4 It is a multistage pump with both end bearings supported. It is sometimes called tie rod comes ring section because his main housing is made by separate suction piece. all held together by large threaded rods.

- BB5 radially split casing multistage and both ends bearing supported pump is driven by the electrical motor by coupled with flexible coupling. It’s also called a barrel type because his housing looks like a barrel it is designed for high-pressure operation.

Vertically suspended

What is the centrifugal pump characteristic curve?

Explain the characteristic curve of the centrifugal pump.

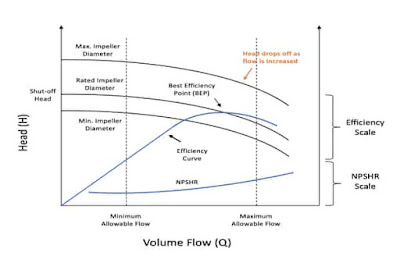

characteristic is a graphical representation of a pump’s defined behavior and performance under the different operating conditions. The centrifugal pump The graphical representation is included five-point pressure, head, flow rate, efficiency, and current.

The characteristic curve shows the relation between four points like

- flow VS pressure head

- flow rate VS power

- flow rate VS efficiency of the pump.

Where is the centrifugal pump used?

API 610 use for oil and gas and petrochemical.

How does a centrifugal pump work?

Centrifugal pump converts the rotational kinetic energy into the hydraulic energy by the help of a rotating impeller. It is work on principle the centrifugal force. When the rotating impeller is rotated it sucks the liquid from the axial direction by the impeller eye then push the liquid by the help of the impeller vans outside in the casing with high speed where pressure builds up in the casing and discharges the fluid to the discharge nozzle.

Advantage and disadvantage of centrifugal pump

Advantage

- The main advantage of a centrifugal pump is that it is operated with full efficiency with a high head.

- Its maintenance is very less and the installation is very easy.

- It takes less space for installation.

- It is available in a large number of configurations. like horizontal, vertical, single-stage multistage, axially split casing, etc.

The disadvantage of a centrifugal pump

- Maintenance frequencies are very high as compared to reciprocating compressors.

- Expensive because the mechanical seal is used in it.

- mechanical seal is a very expensive part of the pump

- it is performance decreasing when operating at high viscous fluid.

- It is not used for high-pressure services.

You can also visit our new article.

| 1 | How To Select Coupling |

| 2 | How To Install Grid Coupling |

| 3 | What Are The Gear Coupling And Application |

| 4 | Important Interview Questions About Shaft Coupling |

| 5 | What Is Fluid Coupling And Advantage Of Fluid Coupling |

| 6 | What Is Rigid Coupling And An Overview Of Rigid Coupling |