What is a Fan?

Fans are mechanical devices designed to create airflow by generating a continuous stream of air or gas. In this section, we delve into the fundamental aspects of fans, exploring their definition, purpose, and the fascinating historical evolution that has shaped their role in various industries.

Types of Fans

Centrifugal Fans

Axial Fans

Mixed Flow Fans

Propeller Fans

Other Specialized Fan Types

Centrifugal Fans

Centrifugal fans, also known as radial fans, are characterized by their ability to generate airflow by accelerating air radially outward. In this section, we explore the design principles, applications, and advantages of centrifugal fans.

Centrifugal Fan Design: Understanding the impeller and housing configurations that define centrifugal fan performance.

Applications of Centrifugal Fans: Examining how centrifugal fans are utilized in various industrial processes, HVAC systems, and ventilation applications.

Advantages and Limitations: Assessing the strengths and considerations associated with centrifugal fan technology.

Axial Fans

Axial fans are designed to move air parallel to the fan’s axis. This section delves into the distinctive features, operational characteristics, and applications of axial fans.

Axial Fan Configuration: Exploring the axial fan’s propeller design and how it influences airflow.

Industrial Applications: Investigating how axial fans are integral in cooling systems, air circulation, and ventilation processes.

Efficiency and Limitations: Analyzing the energy efficiency and operational limitations of axial fan technology.

Mixed Flow Fans

Mixed flow fans combine elements of both axial and centrifugal fan designs, offering a versatile solution for specific applications. This section examines the unique features and applications of mixed flow fans.

Hybrid Design: Understanding how mixed flow fans blend axial and centrifugal characteristics to optimize airflow.

Specialized Uses: Exploring scenarios where mixed flow fans excel, such as in HVAC systems, cooling towers, and ventilation setups.

Performance Considerations: Assessing the efficiency and adaptability of mixed flow fans in various industrial contexts.

Propeller Fans

Propeller fans, also known as axial-flow propeller fans, are characterized by their simple design and high airflow capacity. This section explores the structural components, applications, and considerations associated with propeller fans.

Propeller Fan Structure: Examining the key components that make up the propeller fan and contribute to its performance.

Industrial and Commercial Applications: Investigating where propeller fans are commonly employed, such as in large-scale ventilation and cooling systems.

Limitations and Enhancements: Analyzing the limitations of propeller fans and potential enhancements in specific applications.

Other Specialized Fan Types

Beyond the main categories, various specialized fan types cater to unique industrial requirements. This section provides an overview of these specialized fans, including their designs and applications.

High-Pressure Fans: Exploring fans designed for applications requiring increased pressure capabilities.

Airfoil Fans: Understanding the characteristics and applications of fans with airfoil-shaped blades.

Diagonal Flow Fans: Examining fans that offer a diagonal airflow pattern for specific industrial purposes.

Components of Industrial Fans

– Impellers

– Housings

– Motors and Drives

– Bearings

– Controls and Automation

Fan Selection and Sizing

Selecting and sizing industrial fans is a critical aspect of designing HVAC (Heating, Ventilation, and Air Conditioning) systems and various industrial processes. Here’s an overview of factors influencing fan selection and the sizing process:

Factors Influencing Fan Selection

Airflow Requirements

The required airflow is a fundamental factor in fan selection. It depends on the specific application, such as cooling, ventilation, or material handling. Properly determining the necessary volume of air ensures that the fan can meet the demands of the system.

Pressure Characteristics

Different applications have varying pressure requirements. Fans must be selected based on their ability to provide the necessary static pressure to overcome resistance within the system. Understanding pressure characteristics is crucial for efficient operation.

Temperature Considerations

The temperature of the air being moved by the fan is essential. Fans must be designed to handle the specific temperature range of the application. High-temperature environments may require specialized materials and construction to withstand heat.

Environmental Factors

Environmental conditions, such as the presence of corrosive gases or particulate matter, impact fan selection. Fans made of materials resistant to corrosion may be necessary, and filtration systems may need to be integrated to protect the fan and maintain performance.

Sizing Industrial Fans

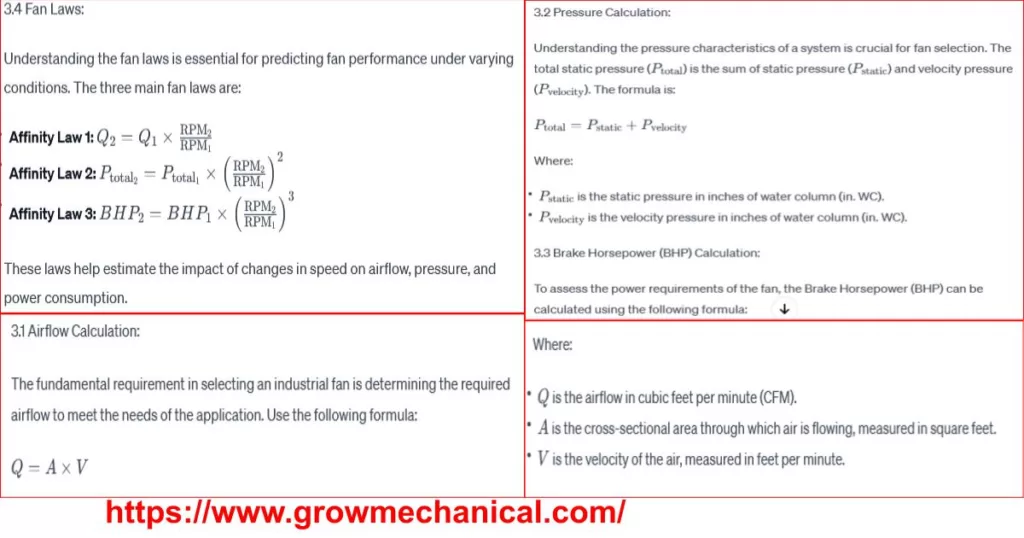

Calculating Airflow

The first step in sizing a fan is calculating the required airflow. This involves considering factors like the volume of the space, the heat generated, and the desired air changes per hour. Accurate airflow calculations are essential to avoid over-sizing or under-sizing the fan.

Determining Static Pressure

Static pressure is the resistance that the fan must overcome to move air through the system. It includes pressure drops from ducts, filters, and other components. Accurate determination of static pressure is critical to selecting a fan that can operate efficiently in the given system.

Matching Fan Performance to System Requirements

Once the airflow and static pressure requirements are known, the fan performance curves are consulted. These curves show the relationship between airflow, static pressure, and power consumption. Select a fan whose performance curve aligns with the requirements of the specific application.

Industrial Fan Applications

Ventilation Systems

– Building Ventilation

– Process Ventilation

HVAC Systems

– Heating Applications

– Cooling Applications

Air Pollution Control

– Dust Collection

– Fume Extraction

– Industrial Scrubbers

Material Handling

– Pneumatic Conveying

– Dust Handling

Process Cooling

– Cooling Towers

– Heat Exchangers

Industrial Fan Applications

Industrial fans find application in various industries and processes, providing essential functions such as ventilation, HVAC, air pollution control, material handling, and process cooling. Here are specific applications within these categories:

Ventilation Systems

Building Ventilation

Industrial fans play a crucial role in building ventilation, ensuring a continuous supply of fresh air and the removal of stale air. They contribute to maintaining a healthy indoor environment in industrial facilities, warehouses, and commercial buildings.

Process Ventilation

In manufacturing processes, ventilation is essential for removing heat, emissions, and contaminants. Industrial fans help in controlling air quality and temperature in workspaces, contributing to employee safety and comfort.

HVAC Systems

Heating Applications

Fans are used in heating systems to distribute warm air evenly throughout a space. They assist in maintaining a comfortable temperature and are integral components in furnaces, boilers, and other heating equipment.

Cooling Applications

Industrial fans are employed in cooling systems, such as air conditioning units, to circulate cool air and enhance the efficiency of heat exchange processes. They contribute to maintaining optimal temperatures in industrial and commercial spaces.

Air Pollution Control

Dust Collection

Fans are essential in dust collection systems, aiding in the removal of airborne particles and ensuring a cleaner and safer environment. They contribute to compliance with air quality regulations in industrial settings.

Fume Extraction

In environments where harmful fumes are generated, industrial fans are used for fume extraction. This application is common in industries like chemical manufacturing, where maintaining air quality is critical.

Industrial Scrubbers

Fans are employed in industrial scrubbers to remove pollutants from exhaust gases. Scrubbers use a liquid to trap and remove contaminants, and fans aid in the proper circulation of air through the scrubbing system.

Material Handling

Pneumatic Conveying

Fans are used in pneumatic conveying systems to move materials through pipelines. They create the necessary airflow for the transport of powders, granules, and other bulk materials in industries like food processing and pharmaceuticals.

Dust Handling

In facilities where dust is generated, such as woodworking shops or mining operations, industrial fans are used in dust handling systems to capture and transport airborne dust to collection points.

Process Cooling

Cooling Towers

Industrial fans are a crucial component of cooling towers, promoting the exchange of heat and facilitating the cooling of water used in industrial processes, power plants, and HVAC systems.

Heat Exchangers

Fans assist in the cooling process in heat exchangers by enhancing the airflow over heat exchange surfaces. This is vital in various industrial applications, including refrigeration and chemical processing.

Installation and Maintenance of Industrial Fans

Installation Best Practices

Proper Mounting and Alignment

- Secure Mounting: Ensure that the fan is securely mounted on a stable foundation or structure. This prevents vibrations and misalignments that can lead to increased wear and reduced efficiency.

- Alignment: Precise alignment is crucial for optimal fan performance. Misalignment can lead to increased friction, wear on bearings, and reduced overall efficiency. Use laser alignment tools to achieve accurate alignment.

Ductwork Design Considerations

- Optimized Ductwork: Design the ductwork system to minimize bends, turns, and restrictions. Smooth airflow reduces energy consumption and ensures the fan operates efficiently. Use proper transitions to match the fan’s outlet size to the duct.

- Avoiding Recirculation: Install the fan to prevent recirculation of air. Recirculation can negatively impact performance and lead to inefficiencies. Consider the location of dampers, louvers, and other components to minimize recirculation.

Maintenance Guidelines

Regular Inspection

- Visual Inspections: Regularly inspect the fan for signs of wear, corrosion, or damage. Check for loose bolts, belts, or other components. Address any issues promptly to prevent further damage.

- Bearing Inspection: Bearings are critical components. Regularly inspect and lubricate bearings according to the manufacturer’s recommendations. Replace bearings that show signs of wear or damage.

Lubrication

- Proper Lubrication Schedule: Follow the recommended lubrication schedule provided by the fan manufacturer. Use the specified lubricants in the correct amounts. Proper lubrication extends the life of bearings and reduces friction.

- Bearing Housings: Ensure that bearing housings are adequately sealed to prevent contamination. Regularly clean and inspect the seals to maintain effective lubrication.

Troubleshooting Common Issues

- Abnormal Noise: Investigate any unusual noises promptly. This could be a sign of misalignment, loose components, or worn bearings. Addressing the source of the noise early can prevent further damage.

- Vibration Analysis: Perform regular vibration analysis to identify imbalances or misalignments. Correct any issues to prevent excessive wear on bearings and other rotating components.

- Monitoring Motor Performance: Keep an eye on the motor performance, checking for unusual heating or erratic behavior. Address motor issues promptly to prevent failure and downtime.

- Cleaning: Regularly clean fan blades and surrounding areas to prevent the accumulation of dust and debris. This helps maintain optimal airflow and prevents imbalance.