Condition-based maintenance (CBM)

Condition-based maintenance is also called (predictive, proactive) in which perform the activity depends on the condition of the equipment. To achieve the maximum production goal and avoid the unexpected equipment failed.

|

Condition-based-maintenance |

Condition-based maintenance has two parts

- condition monitoring maintenance

- reliability-centered maintenance

When Condition-based maintenance (CBM) should be needed and when it to be applied?

1. Mostly Condition-based maintenance applies to expensive and critical equipment used.

2. Equipment overhauling is expensive and required highly trained people to overhaul.

3. Required when it works with high speed and high-pressure temperature equipment,

catastrophic failure could occur.

4. Is this case equipment is operated mostly by remote-based?

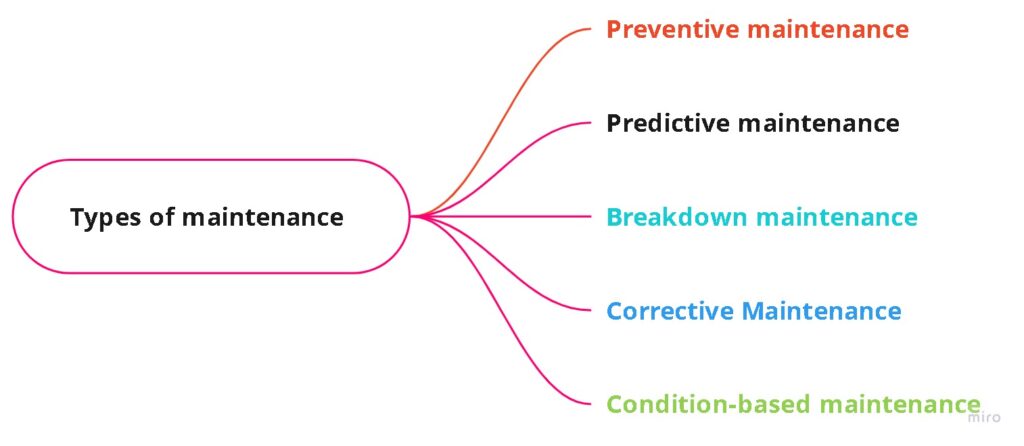

What is maintenance strategy?

There are mainly three types of maintenance strategy

1. Run to failure (breakdown maintenance)

2. Schedule base (preventive maintenance)

3. Condition-based maintenance (CBM)

Above maintained strategy on one is superior or advance to each other. Every strategy has its own value. later we discuss in detail go bottom of the page for follow and subscribe for the latest update.

What is the goal of condition-based maintenance?

The main goal of condition-based maintenance is

- Optimize the maintenance resources and increase the reliability of the plant.

- increase production prevents catastrophic failure from equipment.

- Increase the efficiency of the equipment.

- to improve equipment Safty and integrity.

- Increase the knowledge and awareness of equipment.

- Increase the availability of equipment.

- Reduce the maintenance cost

- It is also part of predictive maintenance.

what type of technics use in the condition-based maintenance system?

There are many techniques used to perform the condition-based maintenance of equipment, piping systems other types of equipment.

- Vibration analysis

- Condition monitoring

- Lube oil and debris analysis

- Ultrasound analysis

- Acoustic emission analysis

- motor current signature analysis, and etc

Difference between preventive maintenance and condition-based maintenance?