What is the role of a maintenance engineer?

The main role of a maintenance engineer is

- Maintaining the equipment.

- Reduce maintenance costs.

- Keep the plants running at reliability and at full capacity.

- Reduces resources like human effort and assets.

- Inspection of the equipment on a routine basis.

- Analysis of the criticality of equipment on the basis of RPN number after which we will discuss it.

- Troubleshooting malfunctioning equipment.

- Manpower management is used in plants to minimize the maintenance cost.

- Overhauling of equipment and its maintenance.

- Make a decision about what type of maintenance to do on equipment, either overhauling or inspection and cleaning only. this is a very important and decision making role.

- Accept safety and follow safety rules and guidelines.

- Aware of the risks and hazards that could happen during the maintenance of the equipment.

There are two types of overhauling maintenance

- Partially overhauling

- Complete overhaul

Partially overhauling

In the partially overhauled equipment, some parts change only like, seal replacement, bearing replacement, lube oil change, seal ring change, greasing the equipment, in it less time to required for maintenance.

Complete overhaul

Complete overhaul in time by taking maintenance in this type of maintenance measure part to be changed like impeller change, rotor change, casing change, or complete internal part to change. It is costly, but sometimes very important to this type of maintenance for capacities increase of particular equipment or plant or equipment to change due to some catastrophic failure happen.

What qualifications are required to be a maintenance engineer?

Who can apply as a maintenance engineer?

- Btech in Mechanical Engineering

- Btech in Electrical Engineering

- B tech in instrument engineering

- Btech in Civil Engineering

- Btech in automobile engineering

Junior Maintenance Engineer

- Diploma in Mechanical Engineering

- Diploma in Electrical Engineering

- Diploma in automobile engineering

- Diploma in Civil Engineering

Responsibility of maintenance engineers

- Maintenanceaintenance engineer should have good communication skills.

- Should be time punctual

- Availability when required, ability to work on large equipment as well as small equipment.

- Good knowledge of reading and understanding of drawing readings like ISO drawings, general drawings (GA), cross-sectional drawings, etc.

- Awareness of soft skills like excel, PowerPoint, MS word, SAP pm, Microsoft project.

- Are you working in a plant? Itself to ensure that he is aware of all equipment maintenance and safety hazards.

- Maintenance engineers should have good knowledge about the inspection of plant machinery equipment parts.

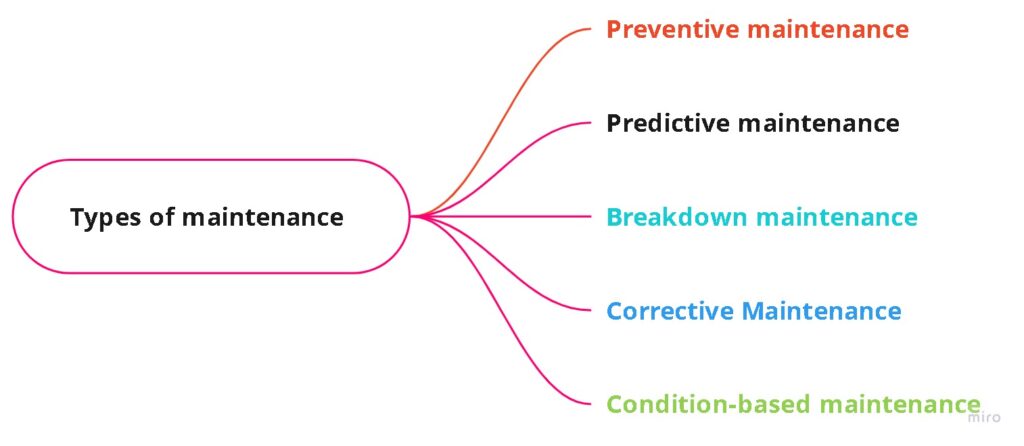

There are many types of maintenance needed.

Types of maintenance include breakdown maintenance, corrective maintenance,

Preventive maintenance, productive maintenance, and condition-based maintenance.

Skills required for a maintenance engineer.

- Inventory control and spare planning.

- Prepare permits, planning to schedule.

- Maintain a recorded history of equipment

- Analysis of equipment criticality RPN numbers.

- Every department has its own maintenance engineer and each maintenance engineer has a different role, responsibility, and skill required.

Instrument engineers will be done only instrument-related, like a probe, control valve, thermowell, etc.

Maintenance mechanical engineer will be done only equipment related maintenance like a pump, compressor, vessel, column, turbines, etc.

Electrical engineer will be done for electrical equipment maintenance only like motor, solenoid valve, etc