What is Nipo Flange?

Nipo Flange is a type of pipe flange that is used in the fluid industries and piping systems. It is a special flange that provides superior strength and superior sealing capability compared to other standard flanges. Nipo Flange is a type of mechanical parts designed for high-pressure pipelines and plumbing systems. It uses with gasket and bolts to create an airtight connection that can withstand up to 10,000 psi.

- It uses a unique combination of pressure bolts and gasket to create an airtight seal which is sustain pressure up to 10,000 psi or 700 bars. This is also makes it from different materials, like steel and plastics upvc and other.

- Nipo Flange key feature it can be use with many types of pipes sizes from small to large diameters.

- It has also been engineered specifically with corrosion resistance capabilities means that they are able to endure much harsher industrial environments than other typical flange that are used in constructing standard mechanical joint, longer product lifespans and better overall performance over time.

- Furthermore, the Nipo Flange is also rated for very high pressures up to 1800 psi depending on selection, which means you can use them safely on both low pressure applications as well as high pressure solutions alike when dealing with gaseous media or corrosive liquids.

Types of Nipo Flanges

There are several different types of Nipo Flange, each with a unique purpose and application. Some of the most common types include RTJ (ring type joint) flanges, flat face flanges and slip-on flanges. Each type of Nipo Flange is designed to offer different advantages depending on the specific project requirements. Depending on the material used, they are all able to handle up to 10,000 psi or 700 bars of pressure.

-

Standard Nipo Flanges

Standard Nipo Flanges are the most common type of flange that are used in general-purpose applications across numerous industries. They are designed to fit a broad range of pipe sizes while still providing adequate support for a variety of piping systems. Standard Nipo flanges are made from A105 steel and come with either raised face or non-raised face designs.

-

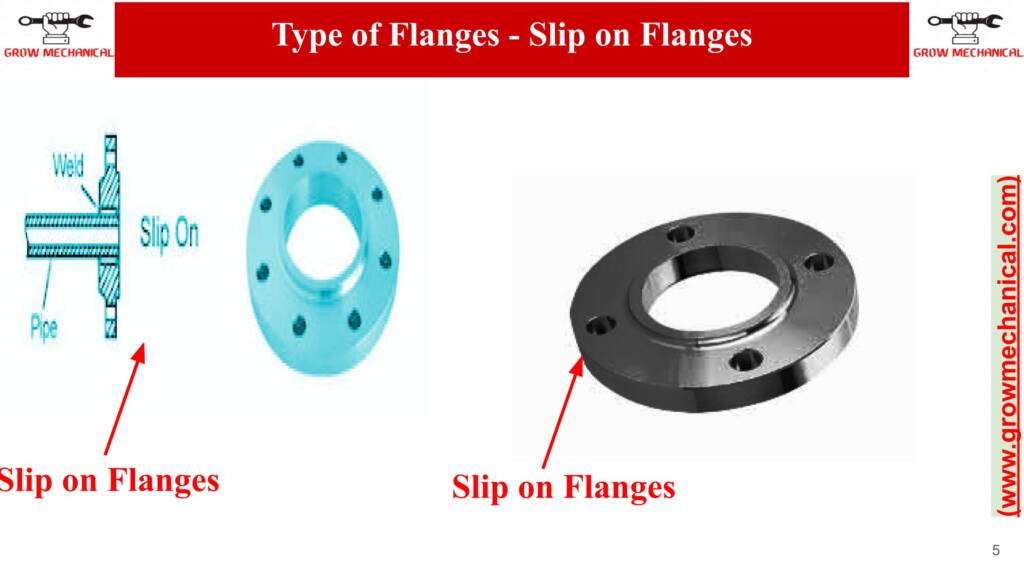

Slip On Nipo Flanges

Slip On Nipo flanges, otherwise known as SOFs, offer several advantages over standard flanges since they need to be welded or machined for installation. This makes them ideal for low-pressure applications with materials such as oil or gas. Usually constructed from A105 steel.

-

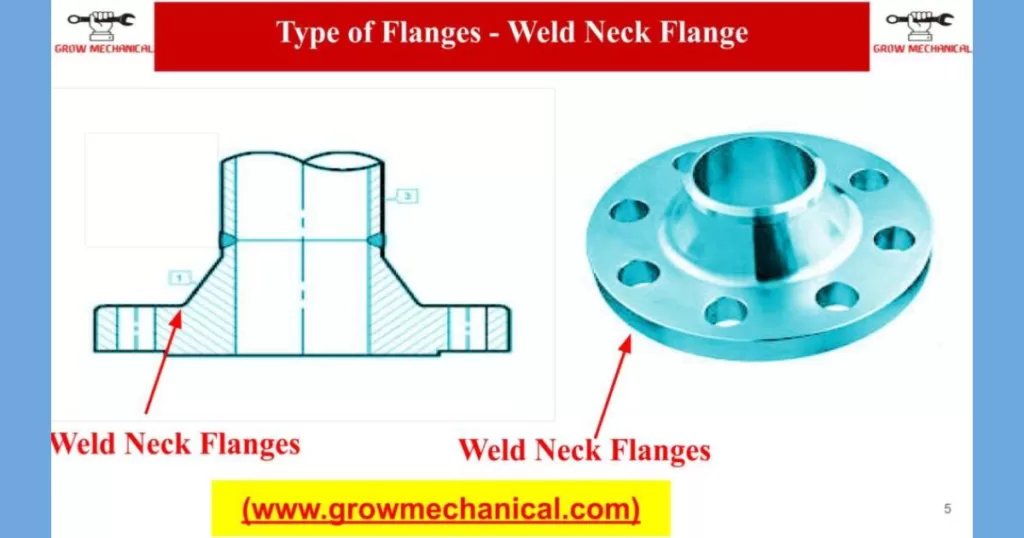

Long Weld Neck Nipo Flanges

Long Weld Neck (LWN)Nippo flanges offer more strength than standard-sized weld necks because they have longer ends which allows them to withstand higher pressures at higher temperatures. These LWNs can be used in various applications including process piping, conveyors, pressure vessels, pumps, and valves.

Applications for the Nipo Flange

Nipo flanges are most commonly used in industrial applications due to their extreme pressure rating and durability. It can also be used in high pressure, pipings fuel tanks, engines or other high-pressure systems. Its versatility makes it useful for almost any project requiring corrosion resistance.

Pipe Joints

Nipo flanges are often used to connect pipes together for strength and securing. The ends of the pipes fit into the grooves on either side of the Nipo flange, allowing a secure connection that won’t easily come apart. This is useful in industrial and commercial applications where pipes need to remain fastened together over a long period of time.

Hydraulic Systems

In hydraulic systems, Nipo flanges can be used as a connector between two or more hoses or pipes that carry fluid under pressure. The secure connection can be beneficial in preventing any leaks or ruptures, as well as avoiding any hazards associated with alternative methods such as hose clamps which may require disassembling and reassembling parts frequently.

Pressure Vessels

The Nipo Flange can also be used for connecting pressure vessels with pipe use at elevated temperatures and pressures such as boilers and condensers. Due to its ability to resist significant amounts of expansion and contraction from large temperature differences in closed loop systems. It’s suitable even when there is no protective coating applied. Generally ideal for power plants, water treatment regulations, desalination projects and oil & gas extraction sites all around the world.

Heat Exchangers

Due to their structural stability at temperatures up to 600°C (1112°F) along with their superb performance at extreme pressures making them particularly suitable for heat exchanger applications.

Plumbing Fixtures

Nipo Flanges are often used in households, most commonly in bathrooms fixtures such as showers because they are corrosion-resistant yet strong enough to withstand water damage and able to securely join fittings together with minimal chances of leaking or creating further damage down the line if something was broken or defective.

The Benefits of Using a Nipo Flange

Nipo flanges are designed for superior strength and a tight seal. They come pre-drilled for easy mounting so you can save time and money. The stainless steel construction provides superior corrosion resistance, making it the perfect choice for wet or humid conditions. Furthermore, the high-pressure design makes it the ideal option for applications that require greater durability than traditional flanges.

- Increased Safety: A Nipo flange is designed to provide a safe, secure connection between two pipes or fittings. The design of the Nipo flange eliminates the potential for dangerous leaks and results in improved safety both at home and in industrial settings.

- Reduced Maintenance: Unlike traditional welding joints, Nipo flanges require minimal maintenance once installed, resulting in reduced costs over time. Additionally, the rubber gaskets are designed to remain water-tight through temperature changes and wear-and-tear.

- Easy Installation – Nipo flange is about as easy as it gets! Special tools aren’t required, just a few basic tools will do the trick – no fancy knowledge needed or skilled professionals.

- Corrosion Resistance: While your local energy provider will update their piping periodically to prevent corrosion from taking hold, that same luxury isn’t always available for residential projects.

- Versatility: Whether you’re looking to join two together pipes quickly or easily replace existing fixtures without having to rework any existing lines – Nipo has got your back! Their design allows them to be used across all types of plumbing projects from irrigation systems through garden hoses up to larger industrial applications.

- Affordable: High quality doesn’t mean expensive when it comes to finding connectors; with prices ranging anywhere between 20% -30% lower than some standard welding options, you can get your hands on high quality connections without feeling the pinch financially!

- Durability: With heavy duty construction including stainless steel nuts and washers as well as flexible rubber seals (designed specifically for grime resistance); you can trust that they won’t rust away anytime soon – making them suitable even for outdoor applications in humid climates!

How to Install a Nipo Flange

Installing a Nipo Flange is not complicated but it is important to follow the manufacturer’s instructions when installing one. In general, you need to ensure that the flange is securely attached to your pipe with bolts and nuts before connecting it to another pipe or fitting. Make sure to use lock washers, as these provide additional security and prevent loosening over time. Finally, apply a silicone sealant to create an airtight connection.

-

Gather the required materials

In order to install a Nipo flange, you will need a jig saw or circular saw, drill, adapter plate, Nipo flange, screws/bolts with washers and nuts, as well as sealant tape. Make sure to consult your local hardware store for further assistance in selecting the right type of material for your project.

-

Mark the area and cut out the opening

Once you have gathered all of the necessary materials, mark the area where you want to install the Nipo flange on the wall using a pencil or marker. Then, use either a jig saw or a circular saw with a straight edge guide to cut out an outline for the flange opening.

- Drill in holes for screws/bolts

Next, you will need to locate a spot at each corner of your opening that is suitable for drilling in holes that can accommodate your screws or bolts. Then use an appropriately sized drill bit and make sure not to go deeper than what is necessary so that you do not damage components behind your walls.

-

Attach adapter plate & Nipo flange

Once all of your holes are complete you can then attach your adapter plate using adhesive caulk or sealant tape along with some screws or bolts with washers and nuts for further stability (you may need to pre-drill some pilot holes into the adapter plate depending on its design). You can then attach the Nipo flange onto this base by simply pressing it into place while applying pressure from behind with one hand while turning it counterclockwise with another until it locks into place when properly aligned.

-

Seal around edges and tighten screws/bolts

Finally, use sealant tape on any gaps around where you have installed both components as this will help keep moisture and air leaks out of your wiring setup respectively (if any are present). Once sealed up sufficiently be sure to check that all connections are securely tightened up before leaving them untouched until usage is needed later on down the road!

Nipo Flange Specification

-

Pipe Flange Specification

A Nipo flange is a type of pipe flange that is used to connect two pipes or tubes together. It consists of two halves joined by bolts and/or gaskets depending on the application, with one half being bolted to the pipe and the other connected to another pipe or tube. This type of flange has a sealing surface so that it can be sealed tightly against another flange’s surface when used in pressurized systems.

-

Bore Sizes

Nipo flanges come in various bore sizes depending on the application, however they typically range from 1/2 inches to 12 inches diameters.

-

Pressure Rating

Nipo flanges typically come with a pressure rating indicated by a number determined based on its bore size as well as its material composition and thickness. For instance, a 10 inch OD Nipo flange made from carbon steel will typically have a rating of 600 psi (pounds per square inch).

-

Materials

The most common materials for Nipo Flanges are carbon steel, stainless steel, aluminum alloy, copper-nickel alloys or brass for standard applications and special alloys such as titanium or hastelloy for more specialized ones.

-

Connecting Methods

Nipo Flanges usually use either slip-on connections or threaded connections depending on their specifications. Slip-on is used mostly in smaller bore sizes while threaded connections are more often employed in larger ones due to the increased strength they provide against higher pressures they may be subject to during operation. Nonstandard connection methods may also occasionally be required depending on specific needs such as grooved connectors or socket welds so choose your connecting method carefully.

6.Coating Options

In some instances an additional layer of protection may also be called for which is where Nipo Flange coatings come in handy – galvanized zinc coating, adhesive polymer coating or terne plate coating can all help extend your Nipo Flange’s life span many times over without compromising performance.

7. Testing Requirements

Once you have chosen your desired specification including their appropriate coatings, remember that any installation must still go through proper testing before being approved – opt for ultrasonic tests which can identify any corrosion or structural damage among other things.

Material of Nipo flange

-

Carbon Steel

Carbon steel is one of the most popular materials for Nipo flange construction. It is capable of resisting corrosion and heat, has a strong tensile strength, and is inexpensive to produce. Carbon steel’s high-temperature performances make it perfect for building steam and other process equipment, and piping systems.

-

Stainless Steel

Stainless steel provides better durability than carbon steel while still being relatively low cost. This material can be useful in firefighting equipment, pharmaceutical processing as well as food handling operations, due to its strong corrosion resistance properties and sanitation benefits. A stainless steel Nipo flange will provide long-term service life.

-

Titanium

Titanium is an incredibly durable material that often produces higher quality Nipo flanges than more traditional materials like carbon or stainless steel. They are bolt-clamp style split faced seals that create a mechanical seal for effective leak-proof gasket seating surfaces with minimal corrosion over time despite rapid changes in temperature during operation in aggressive environments such as saltwater applications, extreme temperatures, acidic solutions or repetitive steam cycling conditions just to name a few!

-

Alloy Steel

Alloy steels contain elements like chromium, molybdenum, nickel etc., which make them more resistant to wear & tear than plain regular steel alloyed components being used in high pressure applications where longer life cycles & higher safety margins are mandatory & critical factors while designing special Nipo flanges. These alloyed products effectively increase their performance capability until they reach their elastic limit thereby making them suitable in high system pressure operations or with machines installing sections where vibrations may be encountered!

-

Copper Alloys

Copper alloys are great for manufacturing Nipo flanges because they are extremely heat resistant and chemical proof, providing excellent corrosion resistance in various environments including hot acid solutions and salt water solutions – even when exposed continuously to moisture or saline water they will not corrode easily making them a perfect choice when working with large diameters on highly corrosive flows that need top insulation from oxidative damage but require no external painting coatings; instead opting for simple polished surfaces since copper plaster themselves with oxidation formed patina substances propagated by time passed through air exposure!

-

Aluminum Alloy

Aluminium alloys are commonly used for heavy duty castings & machine parts due to their lightweight yet robust resilience qualities enabling improved machining savings along production efficiency courses; many casting factories have frequently been producing components from these materials claiming superior finish results due to immense tolerance capabilities shared by aluminum over other traditional materials such as iron so popularly utilized in manufacturing industrial products spread worldwide nowadays – especially those related crafting the category of ‘Nipo Flange’ item categories demanding intricate details which should last longer than usual standards required!

-

Cast Iron

Cast iron provides superior strength capabilities compared to aluminum alloy material and ensures greater levels of stress loading onto bolted joints found at periphery lines requiring far thicker walls before compromising due limitations posed upon narrower dimensional tolerances constraints being imposed – meaning they’re usually cheaper costs associated when choosing one of this versatile substance when opposed to nearby rolled specimens whilst offering equivalent sealing surface pressures after correct preparation operations coupled closely tightening up procedures accordingly implemented or performed properly under proficient experience management practitioners within vast metallic engineering teams masterminded coordination experts proficient task programming programs fully achieved.

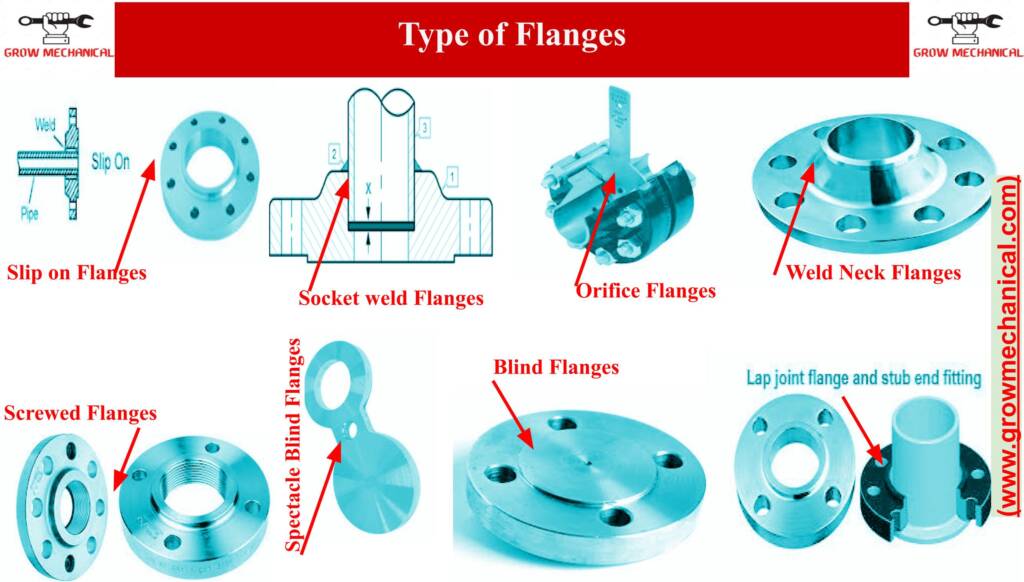

- TYPES OF PIPE FLANGE

- SCREWED FLANGE

- SLIP ON FLANGE

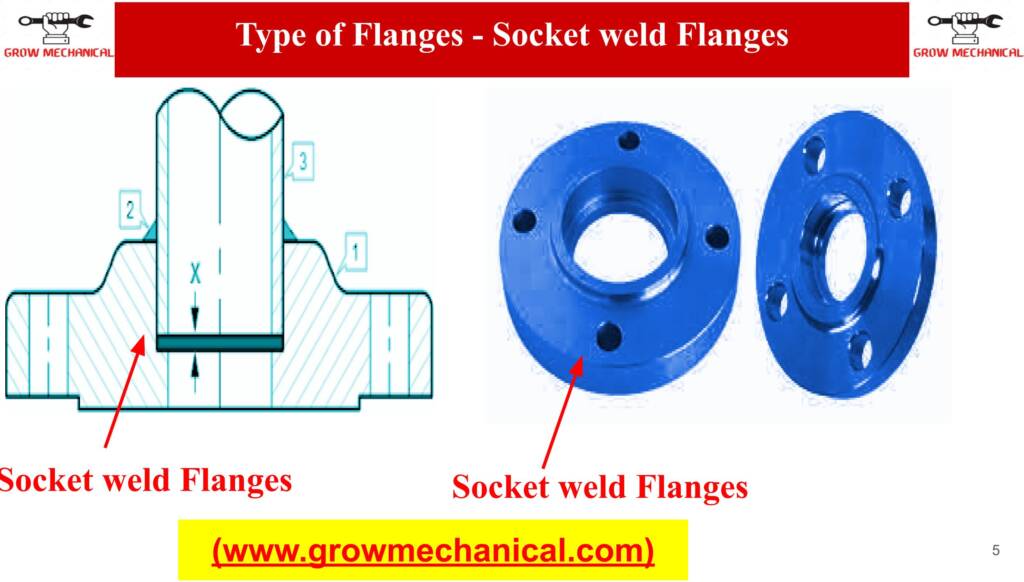

- SOCKET WELD

- SORF FLANGE

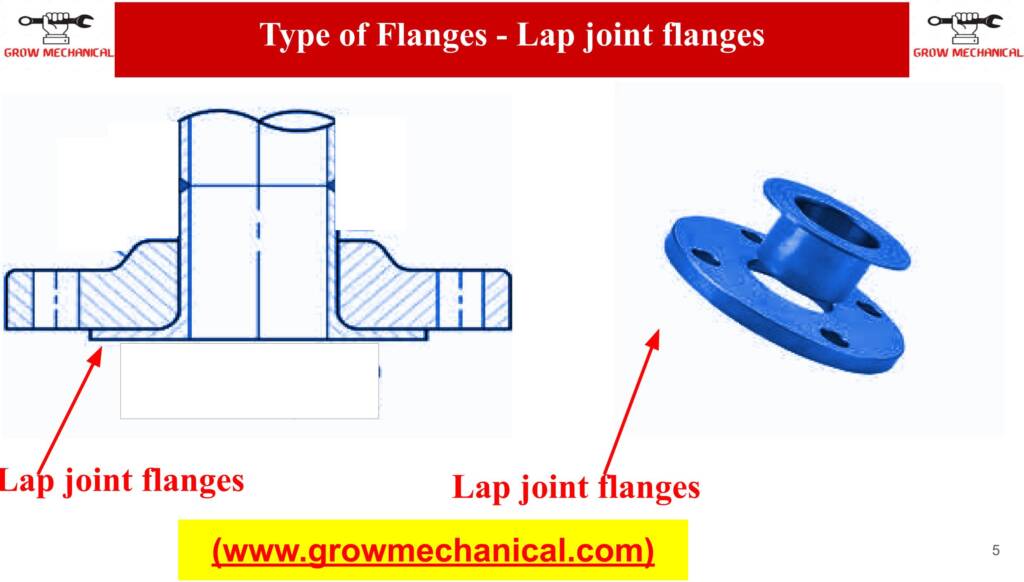

- LAP JOINT