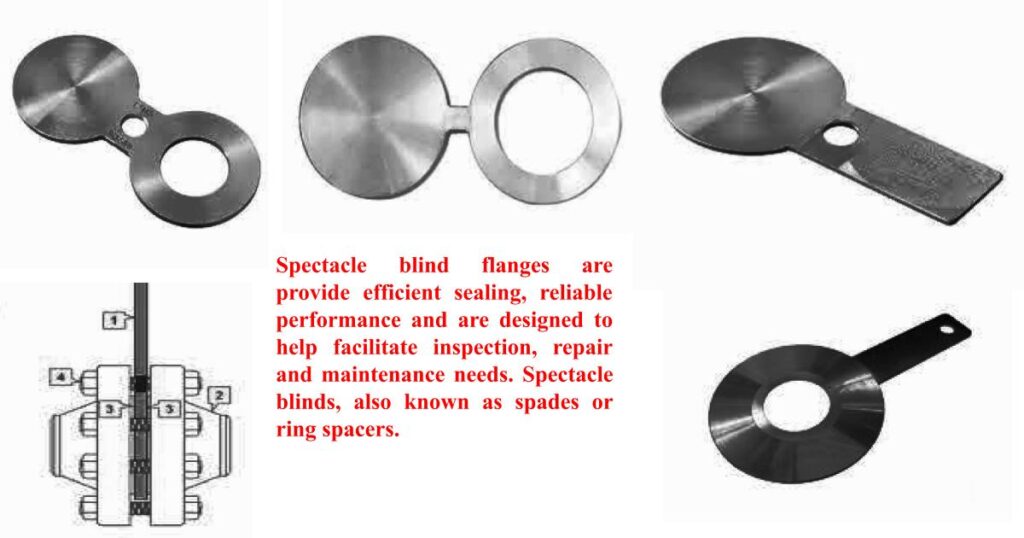

What Is A Spectacle Blind Flange?

Spectacle blind flanges are highly specialized pieces of equipment that can be used for a variety of industrial applications. They provide efficient sealing, reliable performance and are designed to help facilitate inspection, repair and maintenance needs. Spectacle blinds, also known as spades or ring spacers.

A Spectacle Blind Flange is a specialized piece of equipment that can be used in many industrial applications. It features a drilled hole and two gaskets on either side; when assembled, the combination of these components effectively isolates objects while providing a secure and reliable seal. Typically, these flanges are composed of stainless steel or other durable materials.

Applications of Spectacle Blind Flanges

Pressure Testing

Spectacle blind flanges are commonly used in pressure testing of vessels to ensure integrity, as they can be easily removed and installed without having to unbolt any connection points or drain the vessel, and keep the system completely isolated while undergoing inspection.

Isolation

When two sections of a pipe need to remain entirely isolated from one another, spectacle blind flanges come in handy as their design allows for isolation from both sides with symmetrical bolting patterns. This makes them ideal for use when maintaining pressure on one side is necessary even if the other side has been disconnected for repairs or maintenance.

Separation

Spectacle blind flanges are also effective at separating two individual sections that have either very different pressures or temperatures. A lining made of non-metallic materials can be bolted between the two flat faces that help further protect against any leaks or contamination between areas with vastly different characteristics.

Re-fill

Spectacle blind flanges make easy work of sealing off an area temporarily, when maintenance needs to be performed such as an unplanned re-fill in an operating system with liquids of all kinds under different operating conditions and pressures, for example when oil needs to be released from storage tanks and transported elsewhere.

Pressure Flow Regulation

In several demanding applications like chemical reactors where massive amounts of chemicals enter at once and then require careful venting control, spectacle blinds provide a dependable way to regulate pressure and flow simultaneously on both sides of the system before entering a specific part within the reactor vessel that requires closer monitoring or stricter safety protocols than normal operations dictate.

Valve Maintenance & Replacement

Valves fitted within a plumbing installation may require regular maintenance such as replacement or repair; using a spectacle blind ensures that access can be gained safely without fear of spillages during valve removal thanks to its symmetrical design making it easier than ever to install without extra safety mechanisms being employed saving time and labor costs while maintaining optimal levels of safety throughout all operations involved..

Leak Prevention

Lastly, that blind separators can also assist in preventing pressure related leaks over a long period which would otherwise potentially endanger personnel or equipment within close quarters; this means that spectacle blinds play an important role in helping create safe working environment for personnel within hazardous industries like chemical plants where highly corrosive products are often being used .

Spectacle Blind Flanges can be used in a variety of applications, including creating relief pressure outlets, controlling leaks and facilitating inspection, repair and maintenance. They are commonly used in chemical production units, gas pipeline systems and petrochemical plants. When correctly designed, they provide tight seals which remain reliable even when exposed to high temperatures or extreme pressures.

Advantages of Using Spectacle Blind Flanges

Safety

Spectacle blind flanges are generally considered to be the most secure form of flange available. This is because they create a liquid seal between two pipes that prevents any liquids or gas from escaping into the environment and keeps dangerous pressure levels in check. These flanges also provide a visual cue, which makes it easier for professionals to identify where pipes and connections are located, adding an extra layer of safety.

Durability

Spectacle blind flanges are often made from durable materials such as stainless steel or other metals, so they won’t corrode or rust over time like other forms of pipe fittings, making them longer-lasting solutions for attaching pipes together.

Versatile

Spectacle blind flanges can be applied across a wide range of industries and applications due to their unique design and adjustable nature; you can use them in environments with high temperatures and pressures, low-temperature conditions, or even hazardous environments if necessary. They’re also great for connecting two different types of pipes since they provide both a liquid seal and a mechanical connection simultaneously.

Cost Effective

Using spectacle blind flanges saves money – not only in terms of buying and fitting them but also by reducing the cost associated with leaks and maintenance issues that may arise when using other forms of pipe fittings. As well as providing an immediate solution, spectacle blind flanges help companies save money in the long run by eliminating costly repairs caused by environmental factors like weathering or corrosion.

Ease Of Use

Installation is easy – all you have to do is align your two pipes correctly then slide the spectacle blind flange into place (this could take anywhere from 15 minutes to several hours depending on how complicated your plumbing system is). On top of that, there is no need for additional equipment either – all you need is the right tools (e.g., wrenches) and some basic knowledge about how these types of fittings work!

Time Saving Benefits

Because installation is fairly straightforward with this type of product, you won’t have to spend weeks putting it together – it can take anywhere between 15 minutes to several hours depending on your piping setup and your level of expertise/knowledge (you may want to get someone with experience in this area just to make sure everything goes smoothly). This means quicker installation times which equals more time saved!

Improved Performance

By having improved performance due to its strong liquid sealing capabilities, spectacle blind flanges ensure leak-free systems — saving time and money when compared against other conventional pipe fittings methods that might not perform as well under higher pressures / temperatures etc.. In addition, its protective benefits ensure safer working environments – making sure there aren’t any unexpected gas releases into the wider environment due for example poor fitting joints etc.

Disadvantages of Using Spectacle Blind Flanges

Low Strength

Spectacle blinds usually have lower strength than standard flanges as they are simply metal plates inserted between two flanges and held together by bolts or studs, making them much weaker than solid flanges. This can be a major disadvantage in certain applications when strong sealing is required to withstand high pressure, temperature, or vibration.

Cost

The cost of purchasing spectacle blinds may be higher in comparison to other types of flanges because they require additional labor to assemble and install the unit. Additionally, they need more bolts to hold the blank together which also increases the cost of installation.

Limited Options

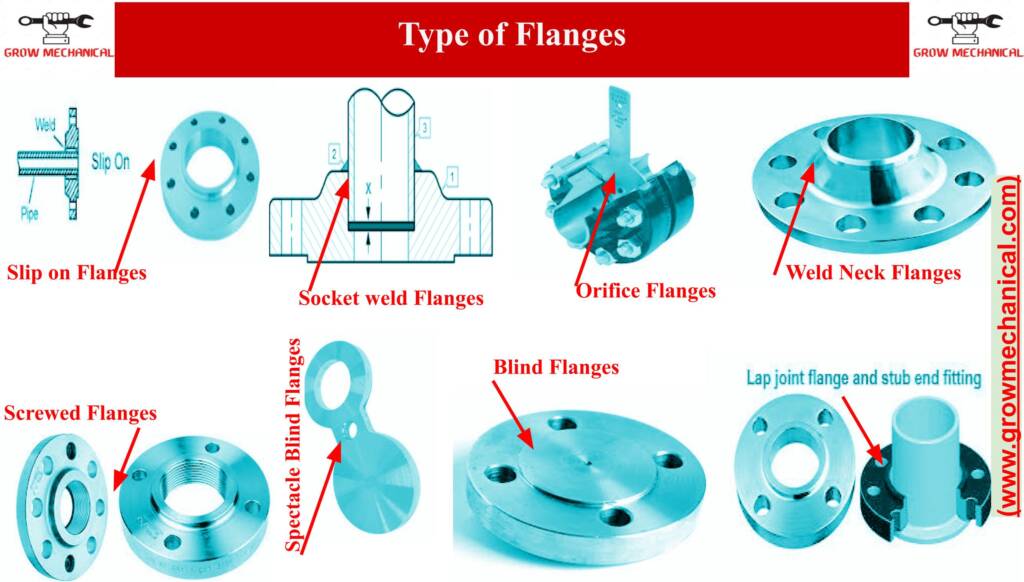

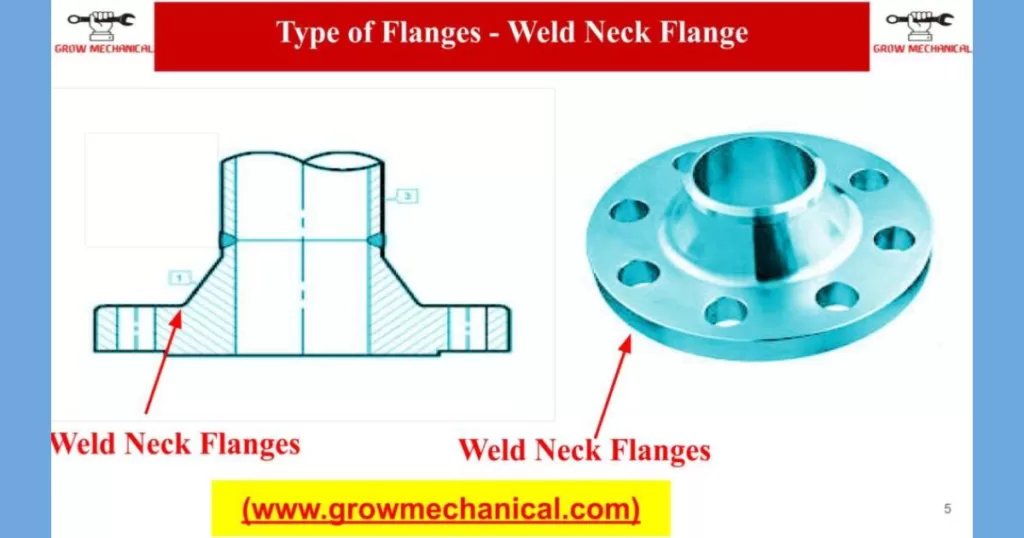

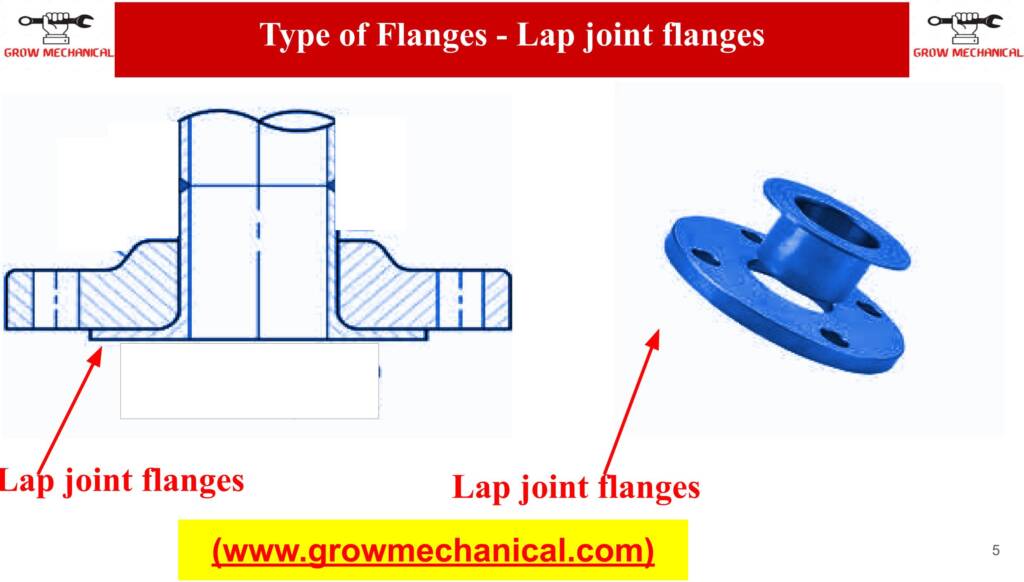

Spectacle blinds are not available in many sizes and materials since manufacturers will typically offer only a few grades for different pipe systems that are commonly used in many industries like oil & gas, and chemical process plants. Depending on your application you may find limited options for spectacle blinds from one manufacturer compared to say slip-on flanges or weld neck flanges which often have a wide range of sizes and materials available for fabrication.

Corrosion Risk

Since spectacle blinds usually feature gasket seating surfaces on both sides these areas can promote corrosion if water accumulates in the confined space over time due to condensation or any other cause leading corrosion effects such as holes formation in the plate reducing its wall thickness until it fails completely during operation time.

How to Select the Right Spectacle Blind Flange for Your Needs

Design Options for Spectacle Blind Flanges

Spectacle Blind Flanges are available in various materials, sizes and design options to meet your needs. These include traditional flat faces, serrated finishes, ring joint faces and integral type designs. They can also be manufactured as per your requirements with bespoke fins or channels customized to your application. It’s also important to choose a material suited to the temperature, pressure and media requirements of the flanges before purchasing them.

Material

Spectacle blind flanges are available in a variety of materials including steel, stainless steel, and chrome-moly, depending on the application. For example, stainless steel is better suited for corrosive environments while chrome-moly flanges offer more strength and temperature protection.

Size

Spectacle blinds come in a wide range of sizes ranging from 1/2 inch to 60 inches. It’s important to consider the size of the flange based on your application as it needs to be able to handle the needed pressure rating and type of material that will be used.

Pressure Ratings

Pressure ratings vary between 300 lbs to 2500 lbs or higher depending on the material and thickness of the spectacle blind being used. It’s best to work with an experienced contractor when determining the right pressure rating for your application as there are several factors that need to be taken into consideration such as environmental conditions and expected loads.

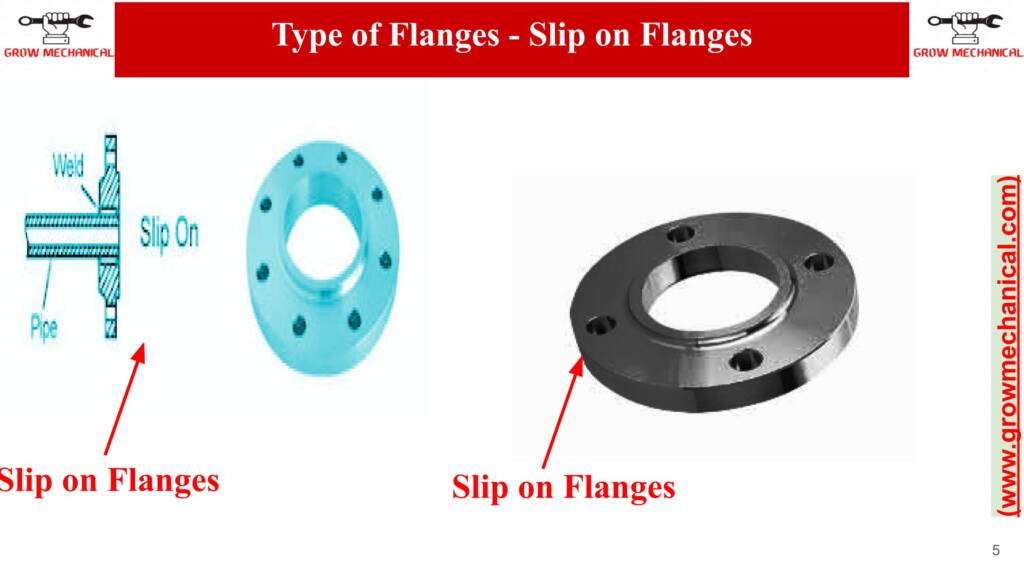

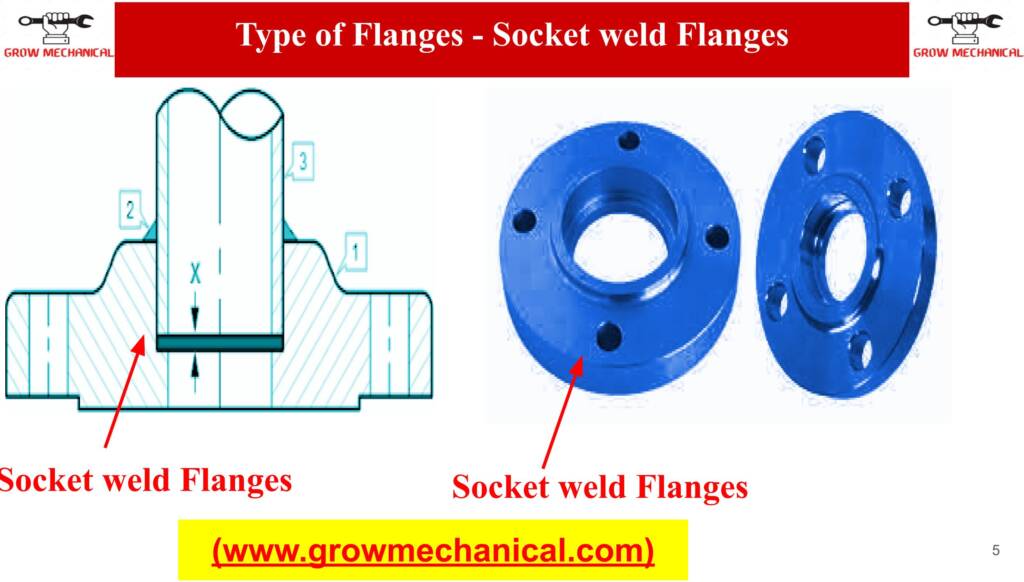

Connection Options

There are various connection options available with spectacle blinds including welded, threaded, screwed, or even none at all (slip-on). The right choice is dependent upon how you intend on mating it into your existing system/piping run so make sure you double check before ordering!

Flange Faces

Another option when selecting your spectacle blind is which faces you want: raised face (RF) or flat face (FF). While RF faces are typically used for pressurization situations due to its ability to contain forces better over time than FF type faces, some applications may require FF faces instead if a liquid does not apply direct force onto them (e.g., wastewater piping).

Coating / Finishes

Spectacle blind flanges can also have protective coatings and finishes applied such as varnish or galvanized surfaces which helps prevent corrosion over time and prolong their lifespan in harsher settings like outdoor/marine atmospheres where additional protection might be needed against rusting or further abrasion damage occurring due environment factors out of control (like moisture or airborne contaminants).

Standards & End Connections

You’ll want to consider what standards apply prior making your selection such as ANSI B16 standard for sizes up through 24″ diameter pipe runs and API 6A afterward; in addition what other end connections will match properly without modifications being necessary (e.g., NPT male threads), ensuring proper fitment both within itself w/o leaks plus adjacent components hooked into it prior-to addressing this setup will save headaches downroad should rework ever become necessary afterwards.

Spectacle blind Types

Double Spectacle Blinds: As the name suggests, these blinds consist of two spectacle blind pieces that are usually used in pipe and vessel systems with high pressure ratings. Usually both flanges sides have one, but they can also be designed in such a way as to account for different sizes and materials.

Weld Overlay Spectacle Blinds

These are similar to double spectacle blinds, but instead of bolts and nuts, this type utilizes welding overlay technology (also known as weld-cladding) to join the two parts together for a stronger seal at higher temperatures and pressures.

Bull Plugs

Also referred to as ‘Bull Plugs’ or ‘Bull Plug Spades’ these devices are best used for simple shut-off applications in gas lines or other piping systems requiring easy and reliable closure of flow through connections. Bull Plugs offer a one-handed operation, allowing quick shut off and connection without the use of wrenches or clamps.

Cone & Threaded Flange Drains

In some situations it assistance might require removal of key components which can be counted by using cone & threaded flange drains so that when those components has been removed than easily put back into place just like same work has never been done before on that area thus making reattachment easier afterward if needed any time soon after service process completion

Orifice Plate Spectacle Blinds

This type is used as an alternative material selection when increased durability is required due to fluids running under high temperatures and pressure, such as chemical feedlines in pipelines transporting corrosive gases or liquids where conventional sights may not be able to handle it properly. The Orifice Plate is mounted between two spectacle frames held by hub bolts into place providing an extremely secure joint connection during operation

Lugged Spectacle Blinds

In order for large sized ASME 150LB class flanges with semi lugged/grooved surface structures will require much heavier design expertise so here enters precisely built lugged spectacle blind having ability to mated with particular kind of groove depths per class rating requirement apart from this modification got attention management quickly in case adjustment became unavoidable thought during provisioning development processes accordingly

Blankers/Spades

Generally these blankers utilize rings design facade created by couple flanges facing each other while sitting opposite each other thus forming figure eight configuration these shape blankers provide excellent performance capabilities due positive pullout designs not only makes them highly reliable but provides tighter pressure seals too while transferring varied hot fluids across challenging pipeline configurations.

SPECTACLE BLIND FLANGE OPERATION

Wear the Appropriate Safety Gear

Before attempting any flange operation, you must wear safety equipment to protect your eyes and face from harm. Safety glasses, a face shield and gloves are all necessary pieces of equipment when performing a flange operation. A full-face mask is also recommended if there is a potential for dust or fumes in the environment.

Inspect All Components Beforehand

Inspect all parts of the flanges before beginning operations, such as repairing or replacing them. Make sure that the nuts, bolts and washers are properly secured to be sure they don’t come loose and injure you during the process. Additionally, check the surfaces of both the mating flanges for presence of debris so as not to disturb it during assembly or disassembly of the piping system.

Clean All Flanges During Operation

Cleaning both surfaces thoroughly with a solvent helps clear away oils, dirt and contamination that can cause leaks later on. Doing this step helps ensure maximum sealing performance every time you assemble your flange connection. The cleaning should include wiping down threads and pipe ends before tightening into place too—to make sure that no extra torque on bolts is needed after assembly to keep them in place firmly.

Use an Appropriate Torque Wrench

For proper sealing performance with long-term integrity it important to use appropriate torque wrenches when working on blind flanges during operation or repair activities—which are not necessarily found in day-to-day pneumatic tool sets! It’s critical to choose one with large calibration and is capable of having enough torque output for whatever specifications you set when securing your fasteners into place (consciously maintaining bolt tension). Plus using a preset device eliminates need recheck threads each time they become disconnected—saving maintenance crews valuable labor hours too!

Maintain Proper Bolt Tension While Assembling Your Flange Joints

It’s absolutely vital to maintain proper bolt tension throughout assembly—to securely compress gaskets between two pipe elements —which promotes better connection airtightness between them! Pay special attention when tightening bolts around corners as tightening sequence appears more crucial here then straight connections where these controls aren’t even considered necessary!

These are generally available in standard sizes up to 24 inches, ranging from ASTM A105 (high-temperature carbon) to A350 low-temperature carbon), and various ASTM A182 grades (alloy, stainless steel, duplex).

FLANGE SPADE VS SPECTACLE BLINDS

Spectacle blind flanges are a useful accessory for controlling the flow of fluid in your pipeline. Available in sizes from 1/2 inch to 24 inches and pressure ratings from 150 to 2500#, spectacle blinds fit a variety of pipelines and are crafted from the same materials used for standard flanges.

FLANGE SPADE AND RING SPACER

Flange Spade Flange

Flange spade flanges are most commonly used in the oil and gas industry due to their superior strength and reliability in demanding environments as they can withstand higher temperatures and pressures than other types of flanges. This type of flange has a solid machined wall that allows for excellent structural balance, sealing capability, and precision fitment. These features make it particularly useful in applications such as high pressure mud pumps or gas turbines that require robust performance at specific locations.

Ring Spacer Flange

Ring spacer flanges are another type of connection assembly that is often used in the oil and gas industry. As its name suggests, it acts as a separation between two mating components which prevents tube kinking when under elevated pressure or movement from thermal expansion or contraction. Similarly to standard flanges, ring spacers are made from carbon steel, stainless steel or aluminum depending on the application requirements. They come complete with all junctions necessary for connection integration – typically Bolts, Studs & Nuts with Gaskets (formed GRP/Rubber).

When the flange is needed for isolation it will be in use as a blanking spade, also known as a single-blind, pad blind, or paddle blind. Spectacle blind flanges consist of two metal discs held together with a small bar. The communicating hole in the disc is made especially to indicate if it is open or closed, as blanking spades feature one single signaling hole on the holder, whereas ring spacers have two holes instead.

Spectacle Blind Flange Materials

When choosing a Spectacle Blind Flange, make sure to select the right materials for your application. Common materials used in Spectacle Blinds include carbon steel, stainless steel, aluminum and other alloys. Consider factors such as operating temperature, pressure rating, chemical compatibility and corrosion resistance when deciding which material is best for your needs.

Spectacle Blind Flanges are available in various sizes, ranging from 1/2 inch (15 NB) to 48 inches (1200NB).

These flanges are available in hot forged carbon or stainless steel to meet the requirements of different applications.

Spectacle Blind flanges carbon steel ASME B16.5 flange composed of two metal discs, known as a “spade” and a “ring.” These unique flanges require exact measurements, made from ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65 ,F70 and A516.60 materials (carbon steel RST37.2 and C22.8). They are often used in piping systems that need clean separation or stoppage so that the pipeline can be worked on safely.

Stainless steel spectacle blind flanges

ASME B16.5 ASTM A182 F 202, F 304/ 304L/ 304H, F 316/316L, F 316H, F 316TI, F 310, F 321, and F 904L are all available to meet your flange needs!

Spectacle blind alloy steel materials

ASTM A182 F1, F5, F9, F11, F22 and F91 according to the ASME B16.5 standard.

ASME B16.5 Spectacle Blind Flanges are special alloy-made flanges that come in a variety of materials, such as nickel alloys, monel, inconel, hastelloy c 276, alloy 20 and titanium. These flanges are also available in duplex and super duplex grades including ASTM/ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61, 2205 (UNS No. S31803), 2507 (UNS No.S32750).

Spectacle Blind Flanges, manufactured to ASME B16.5 standards, are devices used to close off the end of a pipeline. They contain two circular pieces–one solid and one with a cutout–that connect together and resemble spectacles. They are made of copper alloy such as UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, and 71500; or UNS No. C 70600 (Cu -Ni- 90/10), and C71500 (Cu -Ni- 70/30).

They come in three different types: Flat Face (FF), Raised Face (RF) and Ring Type Joint (RTJ).

Spectacle Blind Flanges may be treated with a variety of surface coating treatments, such as anti-rust paint, oil black paint, yellow transparent, zinc plating or cold and hot dip galvanizing. These processes help to protect the flanges from corrosion and provide a longer service life.

Spectacle Blind Flange Codes And Standard

A spectacle blind flange conforms to ASME standards B16.5, B16.20, B16.47 and B16.48, depending on the size of the pipe flange being used. They comply with variety of standards such as ANSI B16.5, MSS SP44, ASA, API-605 and many others including EN1092, B16.5-2009 B16.47-2006 and ASME API 605-1988 or custom specifications based on national/international standards like BS1560-3.1 BS4504-3.1-1989, Afnor nf E29-200-1-2007, ISO 7005-1-1992, AS2129 – 2000 and JIS B2220-2004.

Spectacle Blind Flanges are for high pressure application. They are available in a range of pressure ratings to suit different needs, including Class 150, 300, 400, 600, 900, 1500 and 2500 as well as PN6, 10, 16, 25, 40 and 64.

ASME B16.5 – Specification for Weld Neck, Slip-on, Socket Welding, and Threaded Flanges: A wide range of flange sizes and pressure ratings are covered under this specification with options varying widely depending on the size and type of flange needed. This is one of the most widely used standards, making it one of the best starting points when selecting a blind flange.

2. ASME B16.47 Large Diameter Steel Flanges – Series A & B (API 605): Primarily intended for the oil and gas industry, this standard covers steel flanges over 24 inches in diameter and addresses API standards for larger blind flanges that cannot be found in other specifications.

3. MSS SP – 44 – Steel Pipe Line Flanges: This specification defines large diameter steel line pipe seals as well as blind line pipe seals in various materials including carbon steel or stainless steel construction with raised face connections or flat faces connections when using another seal such as spiral wound gaskets to further enhance their use in hydrostatic pressure testing deployments

4. ANSI B16.48 – Spectacle Blind and Spacer Rings: This is a unique type of spectacled blind line pipe seal that has two slots instead of holes which allow it to be cinched when a fastener is inserted into one side after being placed between two spacer rings in order to seal two products while still allowing them to be exposed like an open valve without being completely exposed to the environment outside

5. ASTM A105N: Commonly known as carbon steel, this material is often used for spectacle blinds since it offers strength at temperature extremes, impact strengths, fracture toughness, and long-term energy absorption capabilities that can limit its use in some applications but can also give it a longer service life when properly used

6. Stainless Steel: Stainless steel is highly corrosion resistant material due to its chromium content which makes it perfect for spectacle blinds as its durability allows them to be installed outdoors where they may come into contact with corrosive elements such as acid rain or salty air near bodies of water

7. Duplex alloy 2205 (S32205/S31803): Made up of both austenite and ferrite phasing which gives it improved toughness over standard stainless mixtures while also giving it improved weldability making them ideal choice selection if you need increased concentration specs compared against just using stainless steel.