What Are Screwed Flanges

Screwed flanges are commonly used in the construction and engineering industries as a secure option for connecting pipes, valves, and other components. In this article, we’ll explain how screwed flanges work and what makes them an important part of many projects.

How Do They Work?

Screwed flanges are fastened to pipes and valves with screws. This forms a very secure connection that can withstand large amounts of pressure. As the screws are tightened, a gasket is compressed between the two components, providing an airtight seal that prevents leaks or contamination.

Types of Screwed Flanges

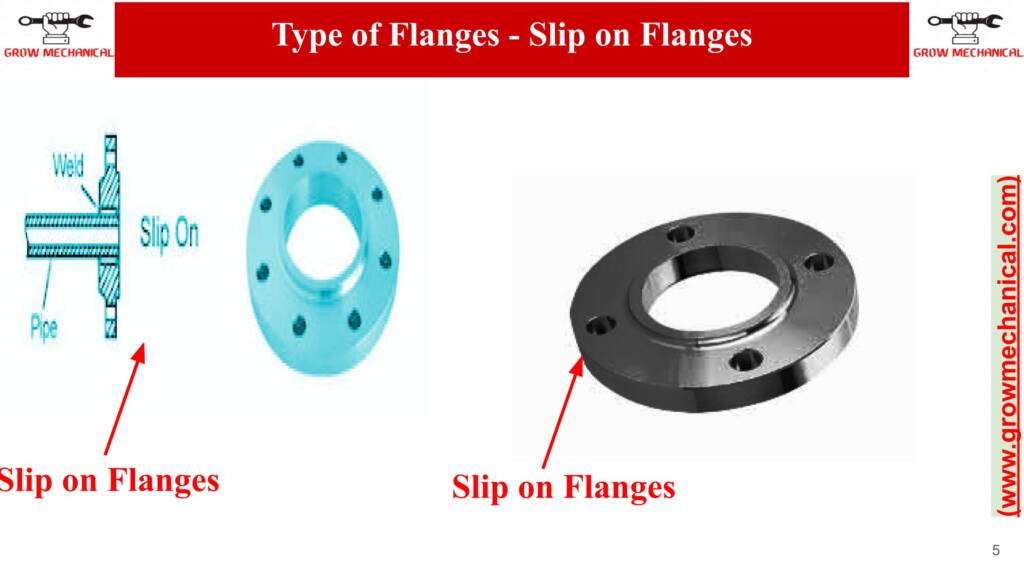

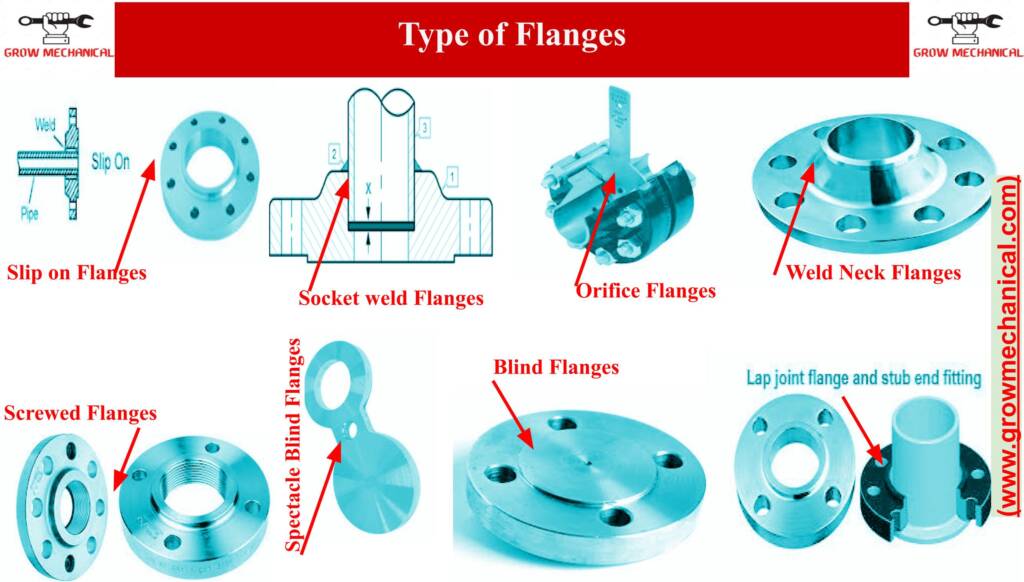

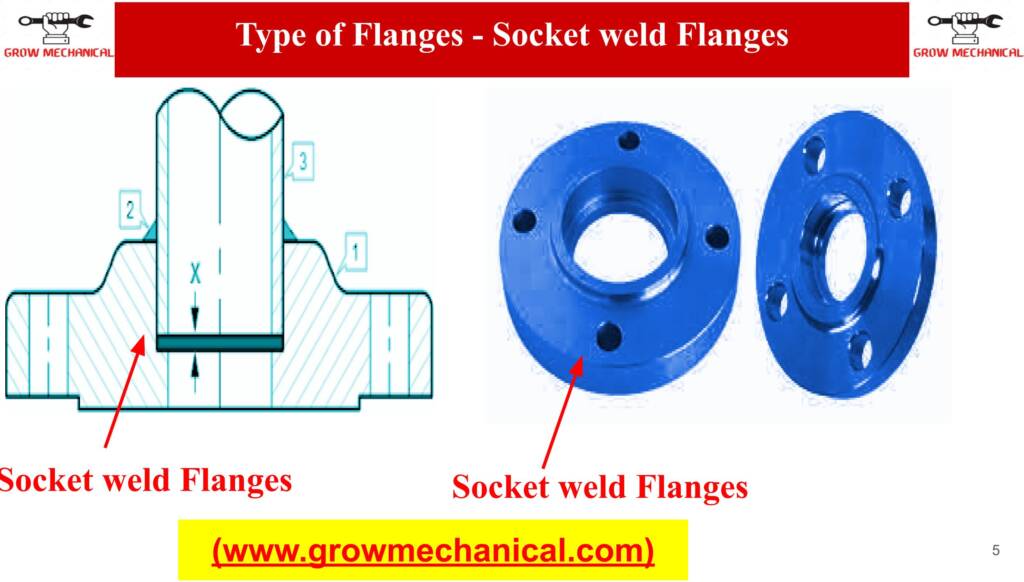

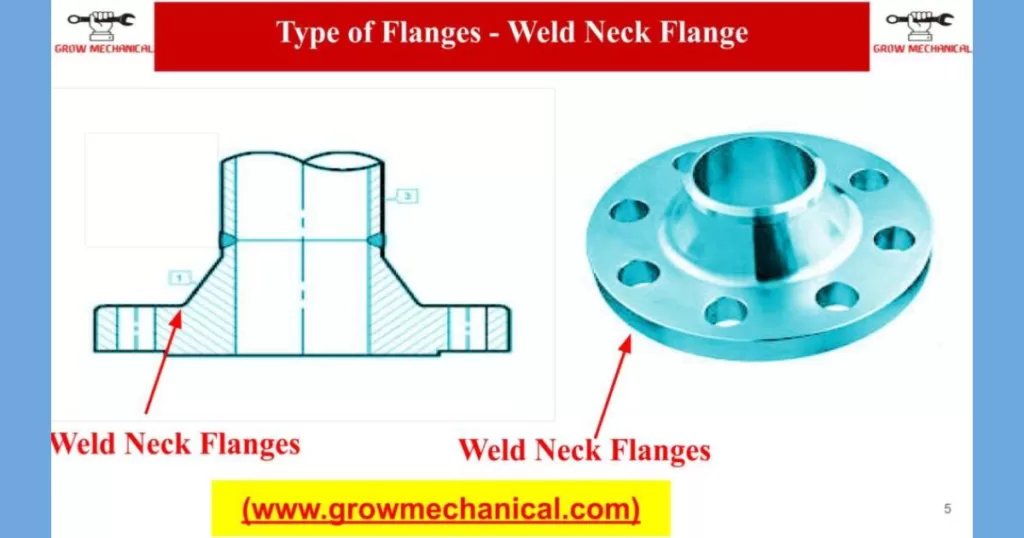

There are several types of screwed flanges available, each designed for a specific application. Blind flanges are used to plug the end of a pipe or tube. Slip-on flanges have grooves cut into their circumference which allow them to attach to the outside of another component much like a sleeve. Socket welded flanges are designed for use in high pressure applications and have a groove that connects it to another pipe or tube along its full circumference.

Why Should You Use a Screwed Flange?

Screwed flanges are ideal for applications where other types of flanges can’t be used. They create a secure and watertight seal between two sections of piping, which is essential for many construction projects. Additionally, screwed flanges are easy to install and require no special tools or equipment. Finally, they have the advantage of being reusable, meaning that they can be taken apart and reinstalled without the need for expensive replacement parts.

Application of Different Flange Designs for Different Needs

Screwed flanges come in a variety of different designs and materials, making them suitable for many different applications. From low-pressure portable cooling systems to high-pressure pipelines that carry fuel, oil or gas, screwed flanges can be used anywhere where you need a watertight seal. Depending on the needs of the project, certain materials may be more suitable than others, so it’s important to research what is available and choose the right design for your job.

Tips for Choosing the Right Screwed Flange for Your Project

Choosing the right screwed flange for your project can be confusing, given the variety of materials, designs and sizes available. The most important factor to consider is the maximum working pressure that the bolted flange must withstand. This will dictate what material you will need to choose. For low-pressure applications, stainless steel is commonly used but for high-pressure systems, alloy steels or copper may be a better choice. Additionally, ensure that you have an accurate measurement of the pipe size in order to properly fit the screws into their designated positions.

Materials

Screwed Flanges are primarily used in piping applications where the primary purpose is to provide a tight seal. They come in several different materials, most commonly forged carbon steel (A105), stainless steel (SS304 and SS316) and molybdenum stainless steel (SS316). All of these materials have good tensile, creep, and stress-rupture strengths at high temperatures and pressures. Screwed Flanges offer excellent corrosion resistance and can be easily welded or screwed into place.