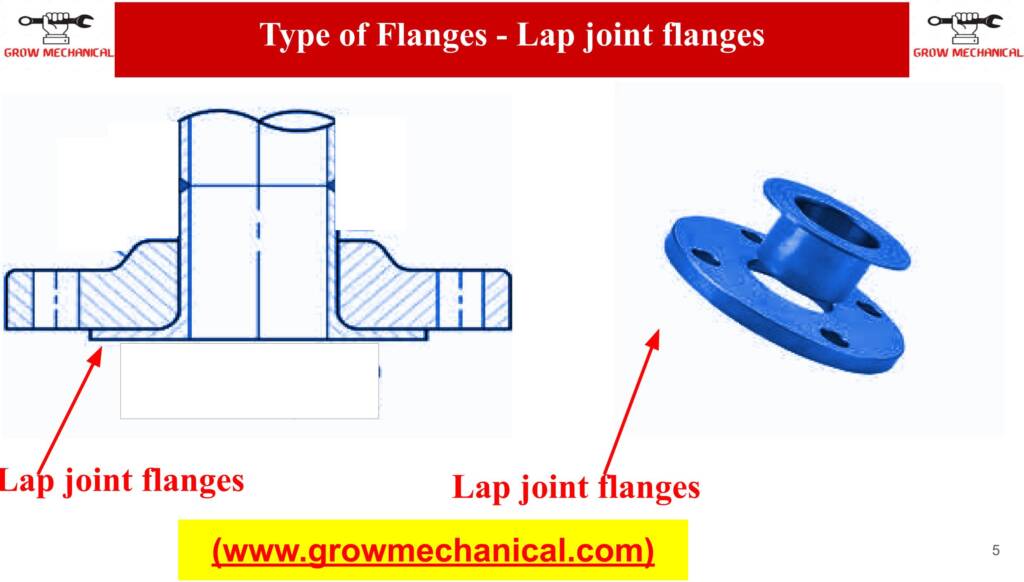

What is a LAP Joint Flange?

The LAP Joint Flange is a pipe flange that combines the strength of lap joints with the easy installation of a flange system. It has numerous advantages compared to regular flanges, including a safer clamping system, cost-effectiveness and ease of installation. Read on to find out more about this innovative flange system, its types and applications, as well as the installation process.

A LAP Joint Flange is a specially designed pipe flange that has two basic components – the lap joint stub end and the backing flange. The lap joint stub end is used to connect two pipes together during installation, while the flange provides extra support and stability for the connection point. This type of flange system offers numerous advantages over traditional flanges, making it an ideal choice for various piping applications.

A Lap Joint Flange, also known as a Loose Flange, is an interlocking joint used in piping systems. This type of flange is not welded or connected to the pipe, but instead is held together by bolts and gaskets. The unique design allows for the outer “stub” and backing flange to be free to rotate on the pipe, making it easier to align the flanges and create a tight seal.

Types of LAP Joint Flanges

There are two types of LAP Joint Flanges – raised face (RF) and ring type joint (RTJ). Both flange styles feature a beveled “lap” on their inner diameter that allows for a “slip-on” connection with the pipe. The difference between the two lies in how they are sealed. RF flanges are sealed with a flat gasket placed between them, while RTJ flanges use a specific grooved shape to provide an o-ring seal, providing superior tightness and strength.

Applications where LAP Joint Flange are used

LAP Joint flanges are commonly used for piping systems that suffer from high vibration or pressure. They are often preferred in applications where the pipe may need to be frequently replaced, such as when fluids of varying temperatures and pressures flow through it. Additionally, because of the beveled lap joint design, they provide additional flexibility by reducing the phenomenon known as “cold flow” that can occur with other flange types.

How to install a LAP joint flange?

Installing a LAP joint flange is a relatively straightforward process. First, the two pieces of pipe must be connected with one end overlapping the other. Then, the bolting surface of the flange can be prepared by grinding it to achieve a smooth and flat finish. Finally, the MDS bolts must be tightened to secure the flange in place before inserting the gasket and O-ring seals. Once everything is in place and secure, your installation should be complete!

How Do Lap Joint Flanges Differ from Rolled Angle Rings?

Lap joint flange is a combination of stub end and a flange for connecting two pieces of pipe or pressure vessels together. The flange has a small gap between the ends and is tightened together by bolts. This setup provides easy access to inspect, clean, maintain, or replace piping components while eliminating leakage paths along the intersection.

It is also known as a loose steel or Vanstone flange, is a pipe fitting that joins two pipes together. Unlike other types of flanges such as weld neck or slip-on, the Lap Joint Flange does not require welding. Instead, it slips over the stub end and fastens with a threaded nut to form a leak-proof joint. This makes it ideal for special applications when welding cannot be done or not possible. The flange has an extended lip which wraps around the end of the pipe and then is secured with bolts to create a tight seal.

As you know this is a two-part flange system consisting of a backing flange and a rolled angle ring. It consists of a stub end, which is sized to fit inside the adjacent pipe or fitting, and an integral collared (or “lapped”) portion at one or both ends. The lap joint flange slips over the pipe allowing easy bending in different configurations. This type of flange offers the advantage of being able to select different materials for each part, allowing greater flexibility in cost optimization. For example, you could pair a 316/L stainless steel rolled angle ring with a carbon steel or galvanized backing flange.

A lap joint flange, also known as a stub-end flange, is a type of steel pipe flange typically used in low-pressure or non-critical applications with systems that require frequent dismantling and reassembly. It consists of two components, a stub-end and a backing flange which is normally a slip-on or weld neck flange. The stub end slides into the hub of the mating flange for a secure but removable connection.

A Lap Joint Flange is a type of flange that is used in piping systems. It is usually paired with a stub end and can be welded or bolted. It has two components – the flange itself, which has slots cut into it, and the stub end, which wraps around the pipe from which it takes its name. The lap joint flange design allows for easy installation and repairs with minimal downtime.

The Lap Joint Flange, or LJF, is a method of connecting pipes, valves, and fittings which are made in accordance with a particular schedule.

A Lap Joint flange is a specialized type of pipe flange used for piping applications. It has two components – the stub end which is welded to the pipe, and the backing flange which rests against the pipe. The backing flange can be rotated so it can line up properly with other connected components, while also providing a measure of flexibility in terms of allowing easy access to the inside of a piping system. Lap joint flanges are typically made from 11-gauge angle iron, although larger pipe sizes may require 7-gauge angle iron.

It is also known as a Pressed Angle Ring or I.D. Pressed Vanstone Ring, is a type of hydraulic flange created from a piece of plate that has been cut to certain inner and outer diameters. These flanges are typically used for smaller rings and are designed to provide strength and flexibility for various projects.

A lap joint flange is a type of mechanical connection that allows for ease of assembly and disassembly, as it produces a continuous ring form with no seams. This type of joint is often used in the production of various components.These components are mostly used in applications where the alignment of two pieces of piping must be precise.

Rolled angle rings are similar in design to lap joint stub ends and can offer comparable benefits. Rolled angle rings are used with lap joints flanges as shown in figure. Rolled angle rings are an important part of the lap joints system because they help to tighten both flanges.

Why Choose Lap Joint Flanges or Rolled Angle Rings?

A lap joint flange is a type of flange that is used in piping systems to connect pipes without having to weld them together. It is made up of two components- a stub end and a backing flange. The stub end is slipped into the pipe and the backing flange is then secured to the stub end using bolts. The great advantage of using this type of flanges is that it makes it easy to assemble and disassemble your piping system without the need for welding.

If you have any doubts about the pressure capacity of a certain flange, then it is best to consult an experienced engineer before purchasing. Allows you to work with multiple materials while maintaining a secure leak-tight connection between components and piped materials. Its flexibility can be used with a wide range of pipe materials due to its unique design. Secondly, it provides easy installation and maintenance as it allows for rotation or realignment of the flange freely.

A Lap Joint flange is specifically designed to be used in high-corrosion or high-erosion processes. This design consists of two parts: a stub end and an angle ring. The stub end can be salvaged for reuse, while the angle rings are replaceable. This makes Lap Joint flanges an economical and safe option for such processes. This makes them ideal for applications where frequent disassembly and reassembly may be required.

The backing flange can come with or without a gasket and is often made of stainless steel or other alloys for added strength and chemical resistance. Lap joint flanges are ideal for projects that require frequent shutdowns or maintenance as they allow for quick access and less downtime.

These flange has a hole at the center, which allows it to fit over the end of a pipe, connecting two parts that can be easily unscrewed or disassembled for inspection and maintenance. These flanges provide excellent strength and have a wide range of applications in piping systems. This flange does not have a facing and the gasket is used to seal the two connected pipes. The gasket itself prevents leakage between them and provides strength.

Difference between Lap Joint Flanges and Rolled Angle Rings

A Lap Joint Flange, also referred to as a Vanstone Ring or a Vanstone Rolled Angle Ring, is essentially the same as a Lap Joint Stub End in terms of design and installation. It has many of the same benefits, though it is slightly less expensive and may be more suitable for certain applications.

A lap joint flange, also known as a Vanstone Rolled Angle Ring Flange is used when connecting to an existing pipe without welding or brazing. This type of flange has a female end that slips over the pipe and has a ring that fits into the groove at the end of the pipe. The ring closes off the flange creating an effective seal for connections with pressurized systems.

A Lap Joint Flange is a type of pipe fitting used to join pipes together. It is composed of two parts, the stub end and the backing flange, that are bolted together to form a secure joint. The backing flange serves as a connector to allow easy disassembly of the pipeline while providing full face contact with other components of the line, making it an ideal choice for high-pressure systems.

A lap joint flange is a type of flange that allows for easy assembly between two pipes or tubes. It consists of two parts; a stub end, which is welded to the pipe, and a backing flange that is bolted to the stub end. This type of flange are commonly used in the food, beverage, chemical and pharmaceutical industries due to its versatility and easy assembly.

Lap Joint flanges are a two-part design made up of both a rolled angle ring and backing flange. This design gives it added flexibility and allows for cost optimization potential by using different materials between the two parts.

A Lap Joint Flange, also known as a Van Stone Flange, is a type of flange design that is composed of two separate pieces: a stub end, which is connected to the pipe, and a loose backing flange that lines up with this to form a welded joint. The lap joint flange here is composed of 316/L stainless steel rolled angle ring with a carbon steel, galvanized backing flange.

A Lap Joint Flange, also known as a Loose Flange, is an interlocking joint used in piping systems. This type of flange is not welded or connected to the pipe, but instead is held together by bolts and gaskets. The unique design allows for the outer “stub” and backing flange to be free to rotate on the pipe, making it easier to align the flanges and create a tight seal.

A Lap Joint flange is a type of flange which has two components. It consists of a stub end, which is sized to fit inside the adjacent pipe or fitting, and an integral collared (or “lapped”) portion at one or both ends. The lap joint flange slips over the pipe allowing easy bending in different configurations.

A lap joint flange, also known as a stub-end flange, is a type of steel pipe flange typically used in low-pressure or non-critical applications with systems that require frequent dismantling and reassembly. It consists of two components, a stub-end and a backing flange which is normally a slip-on or weld neck flange. The stub end slides into the hub of the mating flange for a secure but removable connection.

A Lap Joint Flange is a type of flange that is used in piping systems. It is usually paired with a stub end and can be welded or bolted. It has two components – the flange itself, which has slots cut into it, and the stub end, which wraps around the pipe from which it takes its name. The lap joint flange design allows for easy installation and repairs with minimal downtime.

A Lap Joint Flange connection is a two-piece assembly consisting of a stub end and an accompanying backing flange. The Stub End fastens to the pipe, while the backing flange attaches over the Stub End at a right angle, or lap joint. This type of connection is commonly used in pressurized systems due to its flexibility and ease of installation.

The lap with its gasket is then bolted to the mating flange face-to-face or back-to-back, dropping into grooves on the top and bottom of the flange or shoulder on either side. The traditional material used in manufacturing these Lap Joint Flanges are 11 gauge Angle Iron which may vary depending on the size of the pipe/fitting.

Advantages of Lap Joint Flange

- The advantages of LAP Joint Flange include its flexible installation, cost-effectiveness, and corrosion resistance.

- Its flexibility makes it easy to fit into all types of pipes – rigid or flexible – without having to conduct a full flange analysis.

- The unique design eliminates the need to weld the pipe and flange together, saving time and money in the installation process.

- The flange is corrosion resistant which gives it a longer lifespan when compared to other types of piping systems.

- Lap joint flanges allow for a connection between two separate materials in various scenarios, like backing flange and stub end or angle ring may be different materials, so it has a wide range of applications.

- The stub end or angle ring is usually crafted with material compatible with the fluid passing through the pipe, while more cost-efficient or otherwise preferable material can be used for the rotating flange since it does not come into contact with the process fluid.

A lap joint flange is a type of piping component with two main advantages over regular flanges. - One advantage is that the connection requires no guarantee of perfect alignment or seal – instead, it relies on a gasket and/or o-ring between the flange and the pipe. This makes for an easier installation process than other types of flanges.

- The second advantage of lap joint flanges is their ability to be realigned and rotated freely during maintenance procedures, saving time in systems that require frequent adjustments.

Lap joint flanges are an economical choice for certain applications due to the lack of need for filet welds on the plates with faster installation and overall cost savings when compared to other flange types.

A lap joint flange is an economical solution for reducing the cost of replacing piping components. - The stub end is easily replaced when needed without having to replace the entire product, while the backing flange can be reused due to its resistance to high corrosion and high erosion processes.

Disadvantages of LAP Joint Flange

- Lap joint flanges are typically used in low-pressure applications, as they are not designed to hold up to the same level of pressure as other types of flanges.

- They are most commonly used for exhaust lines and other piping applications where pressure is not a primary concern.

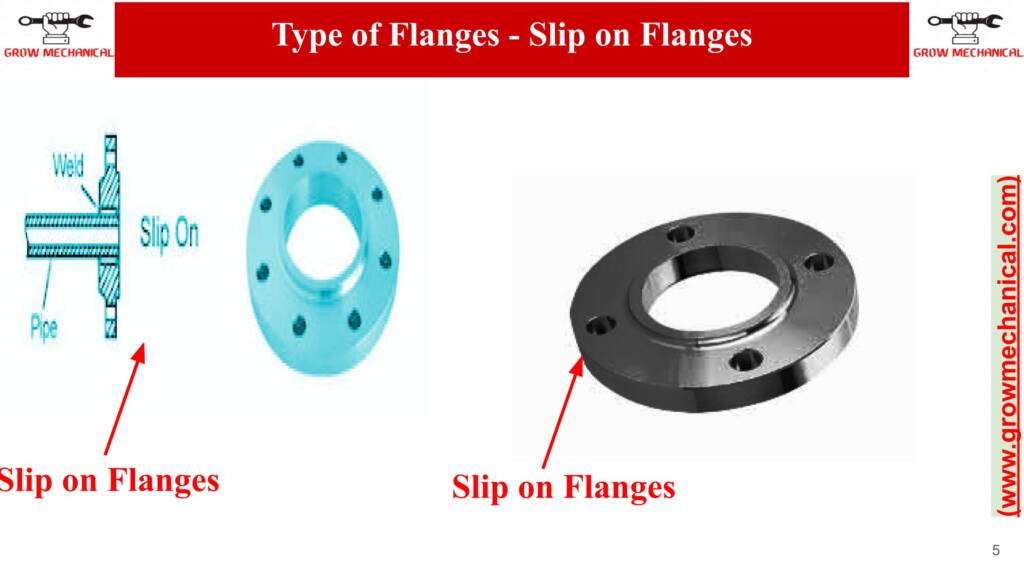

- A lap joint flange is different from a slip on flange in that it is not designed for use in high pressure applications.

- It should be consulted with a piping materials engineer to determine if its suitable for a specific setup. If not weld Neck Flanges are usually recommended as they are better constructed and intended for high pressure scenarios as compared to lap joint flanges.

- That is costly than other types of flanges.

You can also read the following article

- SORF FLANGES

- SLIP ON FLANGE

- WELD NECK FLANG

- SOCKET WELD FLANGE

- TYPES OF PIPE FLANGE