What is a Socket Weld Flange Connection?

Socket weld flanges are a popular choice for pipe installations that require secure and sealed connections. They offer several advantages, including ease of installation and reliable strength when compared to other connection types. Learn more about the benefits, uses, and installation of socket weld flanges here!

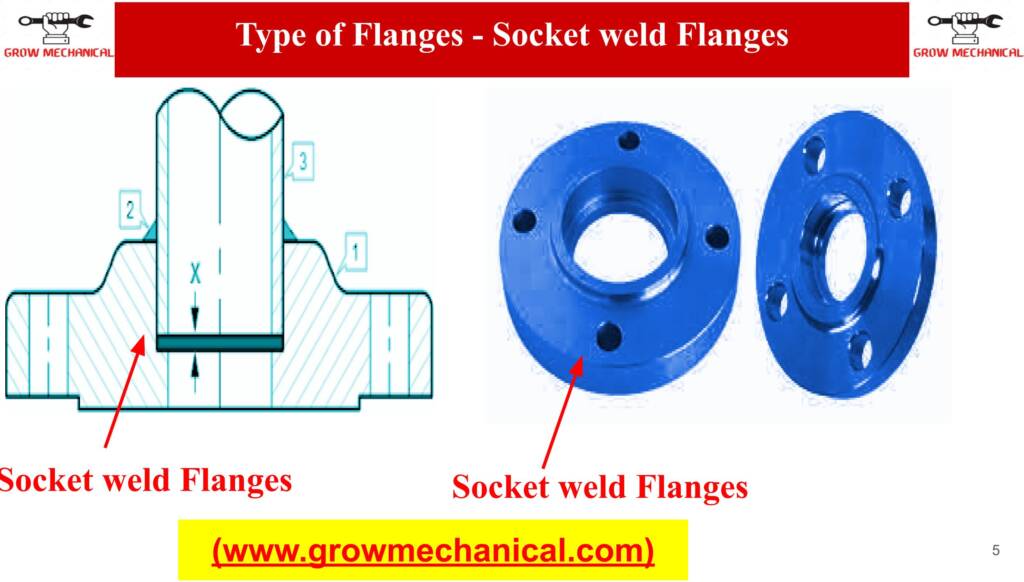

A socket weld flange connection is a type of flange that is used to connect pipes to fittings and valves. It has an enlarged port on the fitting or valve, and the pipe slips into this socket and is then welded into place. This process offers a strong, secure connection that prevents fluid from leaking out. Socket weld flanges can also be used to join pipes at different elevations, which makes them ideal for sanitary systems and piping networks with multiple components.

Socket weld flanges are designed to connect pipes together in a system with high pressure. This form of flange is inserted into the pipe’s socket and secured with a fillet weld on its top for a smooth interior bore, which allows for better flow of gas or liquid. Socket weld flanges are commonly used on smaller sizes of high-pressure pipes.

The installation process for this type of flange involves inserting the pipe into the socket end and then welding it firmly together around the top to provide a smooth interior bore that increases flow efficiency.

Socket Welded Flange Face Types

Socket weld flanges are a type of welding flange, along with slip on, weld neck and blind variants. These two categories are RF type and RTJ type socket welded flanges.

RF Type

A socket weld flange is a type of pipe flange that is generally available in two forms. The first type, known as an RF, has a raised shoulder area around the bore. This area can be used for mounting a gasket to form a tight seal when connecting pipe components together.

RTJ Type

Socket weld flanges are composed of a raised face on which a groove is machined. This RTJ type groove is designed to hold a gasket ring, thus allowing for better sealing to keep liquids from escaping or entering the system.

Benefits of Socket Weld Flanges

The primary benefit of socket weld flanges is their ease of installation. Because they do not require any specialized tools or complicated fabrication, they can be quickly assembled with minimal effort. Additionally, socket weld flanges are known for their strength and durability due to the tightness of the connection. This makes them a great choice for applications that require a secure and sealed connection, such as in sanitary piping systems or chemical plants.

Common Applications of Socket Weld Flanges

Socket weld flanges are typically used in high-pressure applications. They can be found in a variety of industries, including chemical processing, desalination plants, power generation, mining and mineral processing, pharmaceuticals, food and beverage production and wastewater treatment. Additionally, due to its superior strength and reliability when compared to other connection types such as threaded or butt-weld fittings, socket weld flanges are often used in hazardous environments that require robust connections.

Common Specifications for Socket Weld Flanges

Socket weld flanges come in various sizes, materials, pressure and temperature ratings, depending on their application. Commonly used specifications and standards include ASTM A105 for carbon steel flanges and ASME B16.5 for stainless steel flanges. The most popular materials used to construct socket weld flanges are carbon alloys, stainless steel alloys such as 316L, nickel alloys such as Inconel 600, Hastelloy C276 and Monel 400, and non-metallic flanges such as those made of plastic or BRZF (Bronze Filled).

Socket Weld Flanges and Their Advantages

Socket weld flanges are available in a variety of configurations, including Class 150 (a pressure rating for flanges below 300 lb) and blind. Then comes the Class 300 Stainless Steel Flange with a pressure rating between 600-900 lb and raised face flange fitting with an internal socket weld to connect pipes that have already been welded. Socket welding also keeps their connection secure and sealed properly, eliminating galling, corrosion or leaks. Furthermore, as opposed to slip on flanges which require more space due to their height due to welding gap requirements, socket weld flanges are perfect for space-restricted areas.

How to Use Socket Weld Flanges

These are designed to be welded onto the pipe, with a space between it and the flange. To install, insert the pipe end into a socket weld flange until the bottom of the pipe touches the shoulder area, then pull back 1.6mm (1/16”) away from the inserted pipe. Finally, perform fillet welding to fill the gap between flange and pipes or fittings.

Available Material

A socket weld flange is a type of pipe fitting that connects a piece of pipe to an existing line and are most commonly used for small diameter piping with pressure ratings between Class 150 and Class

How is Socket Welding Flange Generated?

Socket weld flange is a kind of flange that is used to connect two pipes together. It was originally designed for use with stainless steel superheaters in order to prevent any cracking from the thermal stresses inflicted during the heating process. Over time, it has become a common application for various materials due to its reliability and durability.

Advantages Of Socket weld flange

Socket weld flanges offer an alternative to threaded flanges, minimizing the potential for leakage. These types of flanges are designed to prevent any pathways for fluids or gas to escape, making them a popular choice for many industrial applications.

Socket weld flange is a type of pipe connection that does not require the use of beveled edges before welding. This allows for faster and easier installation process, making it an ideal option for those who are looking to save time in their projects.

Socket weld flanges are a type of welding fitting used in piping systems where the welding work is done outside of the pipe and does not penetrate into the bore of the pipe.

Socket Weld Flanges are designed for applications where internal welding operations are difficult, featuring a welded construction to create a flush joint. This allows for the elimination of pockets within the interior and reduces warping from welding heat or damage to the flange face from weld spatter. Socket Weld Flanges also maintain the same level of internal pressure as that found in a sliding flange, resulting in an increased fatigue life.

Disadvantages Socket weld flange

Socket welded flanges are used to create secure, reliable connections between pipes. This requires a high level of skill from the welder because there must be a gap of 1/16 inch between the pipe and shoulder when the welding is completed.

A socket weld flange is a pipe fitting designed to be connected to a pipe via a relatively low-pressure socket weld. This type of connection is typically used for pipes carrying high-pressure fluids, as it greatly reduces the chances of crack defects and allows for better strength and corrosion resistance. The welding process involves completely welding through the pipe from outside to inside, forming an incredibly strong joint that can withstand extreme pressure and corrosive materials.

Socket Weld Flange vs Slip On Flange

The socket weld flange is a type of pipe flange that fits between two pipes or fittings. It consists of a round collar with an opening at the end, which is inserted into the end of one of the pieces to be connected. The flange also has a shoulder built into it, forming an inner bore that accepts the other piece welding material when fitted together.

Socket Weld Flanges are a type of pipe flange that attach to pipes via a socket welding process. It is a circular fitting with female threads on its inside bore, creating a highly secure seal between the connected pipes or fittings. Socket Weld Flanges use an overlap between the connected pieces, eliminating the need for any shoulders in the inner bore.

When compared to a double welded slip on flange, socket weld flanges have a static strength that is the same but better fatigue strength by 50%.