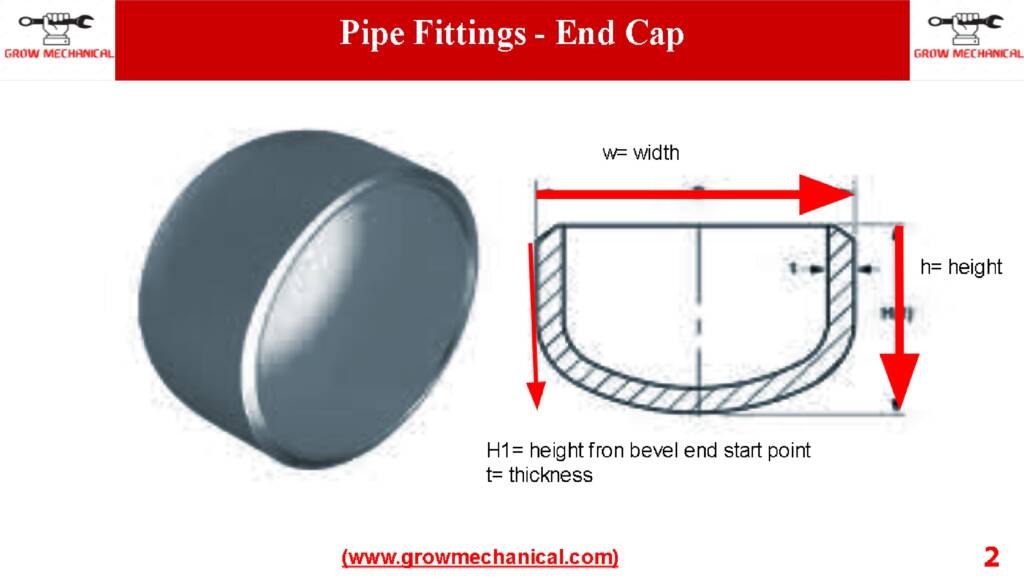

End cap pipe fitting Introductions

End cap pipe fitting is a type of pipe fitting which is used on the end of a pipe/tube or equipment nozzle. The main purpose of the end cap is to protect the leakage from the pipe end or isolate the pipe end as well. That is available with the following types of connection like a weld joint, threaded end, socket fitted.

Connection of end cap pipe fitting totally depends on service fluid and the nature of its hazards. Threaded type end cap may be with a male or female thread connection between pipe/tube and in other case end cap may be welded on to the end of the pipe/tube. The general purpose of end caps is to protect the end of pipe, equipment and other fittings, so the standard of end caps is the same as the pipeline.

Material used for construction of end cap pipe fitting

There are different types of materials used for construction of end cap theses as follows: Aluminium, Carbon Steel, Cost Iron, Nylon or Polyamide Polyethylene Polypropylene Stainless Steel Vinyl Silicone rubber etc.

Types end cap pipe fitting

It is available in many shapes like Round, Square, Rectangular, U Shape, I Shape, Hex End Cap etc.

What are the advantages of pipe end caps?

- It is useful to close the unused pipeline by cutting and installing at ends of the transported or stored pipe.

- This will prevent contamination of the pipe interior from dirt, dust, water, snow, animals, etc.

- That is useful for reducing pressure drop as compared to other pipe fittings.

- Cost savings by installations of end caps and it can be re-used multiple times.

- Installation and removal are very easy and not more tools are required for the same.

Dimensions standard End Cap

Important dimensions standard for End Caps Pipe Fittings like materials Carbon and Alloy Steel are

- ASME B16.25, ANSI B19.28, MSS-SP-43

- DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

- EN10253-1, EN 10253-2

- Seamless / ERW / Welded / Fabricated

the above mentioned chart is use for reference purpose only and that is taken for Asme standard b16.9

the above mentioned chart is use for reference purpose only and that is taken for Asme standard b16.9

Application of end cap pipe fitting

Food processing, Architectural railings, Pharmaceutical and chemical process plants equipment like Heat exchangers Threaded fasteners, Springs Industrial fabrications etc. That is also used at the end of TEE fitting.

Selection of end cap pipe fitting

- There are many parameters for selecting an appropriate pipe end cap, some of the important are given below.

- Choose DN (nominal diameter) of pipe like 50NB (2″).

- Height of the end cap as per user requirements

- Select the dimensions standard ASME B16.9, MSS SP-43.

- Select the design standard ASTM A234 GRADE WPB, ASTM A105, ASTM F1545.

- Process of end cap fitting fabricate (Seamless or ERW, Electric resistance welding).

- Select the (MOC) materials of construction for your fitting, like mild steel (MS), stainless steel (SS), carbon steel, etc.

- Select Class or Pressure rating or Schedule, according to your piping design.

- What type of end connection is required, Plane end (PE), Bevel end, Flange end, Threaded end, or direct fit to pipe?

- Types of weld required Socket weld or Butt weld.

- Corrosion resistance

- Durability