What is a Square Flange?

Do you need to attach pipes in a certain arrangement, or secure heavy machinery? If so, then a square flange is the ideal piece of hardware for the job. It features a flat plate with four holes around the edge and can be used in many different configurations depending on your needs.

A square flange is a type of flat plate with four holes around the edge. It is most commonly used to attach pipes or machines in different configurations. The flange can be made of different materials, so you’ll need to choose the right one for your particular job. Additionally, there are many sizes and shapes available, so you should make sure you pick the right size that will suit your needs.

What Types of Square Flanges Are Available?

Square flanges are available in different materials and sizes to suit a wide range of applications. Common materials include stainless steel, carbon steel, brass, or aluminum. The flanges come with various features such as holes and threaded patterns. Additionally, they can also be customized according to specific requirements by machine shops.

How Do You Install a Square Flange?

Installing a square flange is an easy task. To begin, ensure that the mating parts are clean and free of any materials or obstructions. Once this is done, holding two bolts in each hole, start screwing them together until the square flange is firmly attached to its mating part. Apply thread lock compound along with the bolts for a secure connection. Finally, check for leaks to make sure that your connection has been properly sealed.

What Materials Are Used to Make Square Flanges?

Square flanges are typically made from steel, stainless steel, aluminum, brass, or plastic. The materials used depend on the application and environment in which the flange is being used. Steel flanges may be galvanized in order to provide extra protection from rust or corrosion. Stainless steel offers excellent strength and resistance to corrosion, making it a popular choice for many industrial applications.

Advantages of Square Flange

- Easy to Install – Square flange is a very simple and easily installed part, since they have half (or three-quarters) holes in each corner, rather than having round holes, meaning that you don’t need any sophisticated tools. This makes them easy to put together as they can simply be bolted on using standard bolts and nuts.

- Variety of Sizes – Square flanges are available in numerous sizes so it’s easy to find one that will fit your project without a lot of problems or modifications needed. Furthermore, it can be cut or bent into different shapes to help fit custom projects better.

- Low Cost – Square flanges are typically less expensive than other types of flanges due to their reliance on simpler materials and easier installation processes which reduce costs significantly over time.

- Versatility – Square flanges have multiple uses, from connecting pipe lengths to connecting equipment such as ductwork and filters in indoor HVAC systems, making them a versatile addition for any construction or home improvement project alike.

- Reduced Leaks / Increased Seals – Since square flange has four steel corners where bolts attach instead of just two sides found with a round bolted connection setup they provide increased strength reducing the chance of leaks as well as providing a tighter seal when everything is tightened appropriately

- A square flange allows incredibly versatile and customizable configurations when compared to other fittings. This makes it a great choice when creating a complicated or specific set up. Furthermore, its increased strength offers improved safety and reliability when handling hazardous materials or working in complex construction projects. Square flanges are also cost-effective as they can be re-used, making them a great option for budget-conscious businesses.

Disadvantages of Square Flange

Installation Difficulty – One of the first disadvantages to installing a square flange is how difficult it can be. Since there are 4 sides instead of just 2 or 3, it can take more time, skill, and effort to install one properly.

- Lower Strength – Despite being widely used in industry, square flanges aren’t as strong as other types of flanges such as elliptical head types. Since they cannot disperse the forces applied evenly throughout the four sections they offer lower strength than alternatives.

- Costly – Due to their complex shape compared to other flange styles like slip-ons or blinds, square flanges tend to cost more money than other more common variations.

- Bore Obstruction – One of the major concerns for using a square flange is the obstruction that occurs during bolt installation and pipe connection due to their unusual shape design. Not being able to get around corners creates varying clearances for bolt installation which requires extra attention during assembly work procedure and makes this even more costly and time consuming as well as increase likelihood of errors in fittings within piping systems .

- Space Limitations – Square flanges have quite an extended design when compared with their round counterparts, which means they take up far more space both horizontally and vertically while installed into any structure or item you may use them in conjunction with such as piping systems, machinery or vessels etc

- Stress Concentration- Square flanges come with the disadvantage of having very large stress concentrations on the sides due to their unique design which is generally not seen with round based designs; this could absolutely lead to fatigue failures if not accounted for correctly otherwise should downfalls arise from such changes in material properties at certain locations on those faces stress values will exceed what was originally assumed safe limits causing failure in some cases .

- Poor Corrosion Resistance – When it comes to corrosion resistance square flanges are sorely lacking when compared with other designs thus requiring additional coating risk protection measures when installed into areas where gasses may be present that could cause rapid degradation over short periods.

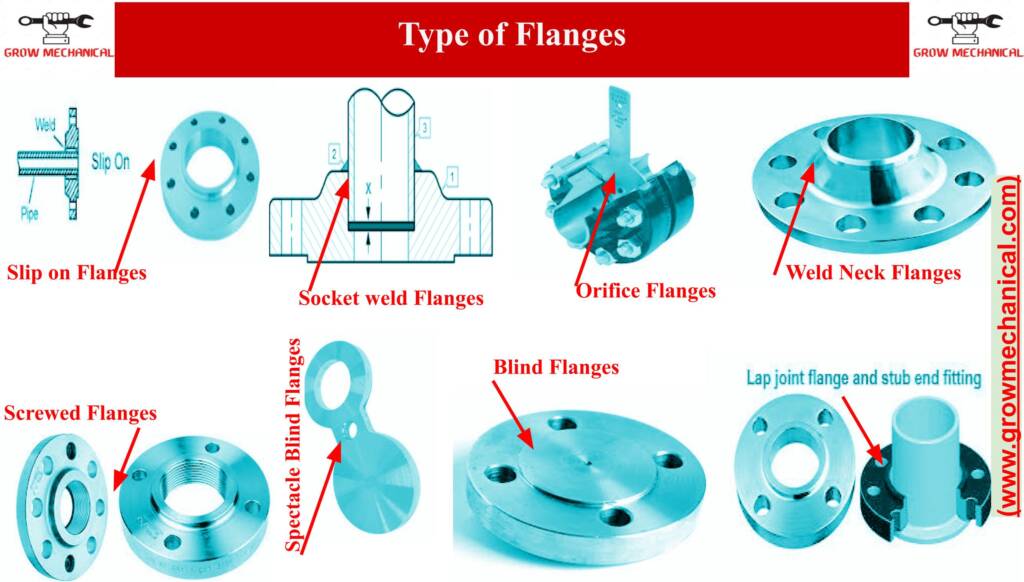

- TYPES OF PIPE FLANGE

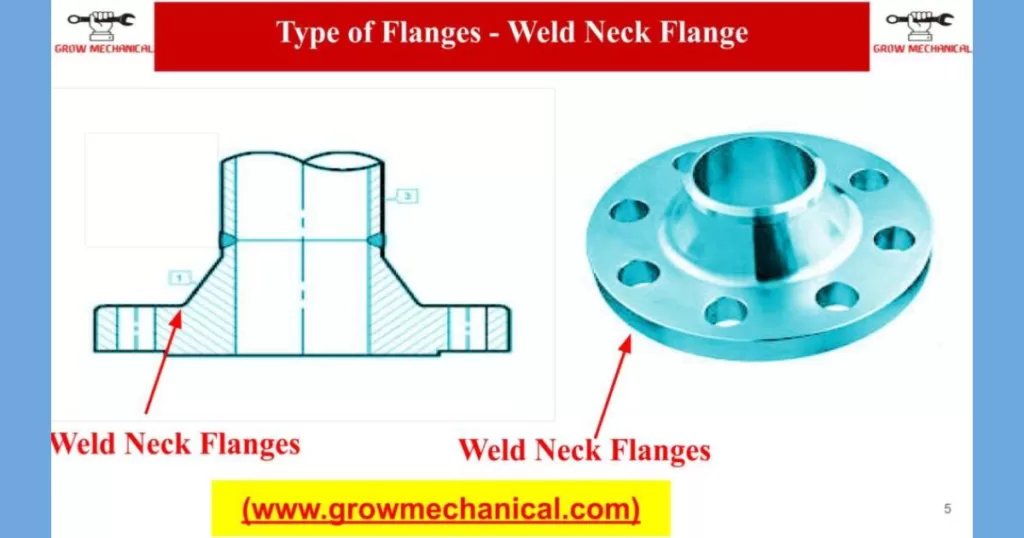

- WELD NECK FLANGE

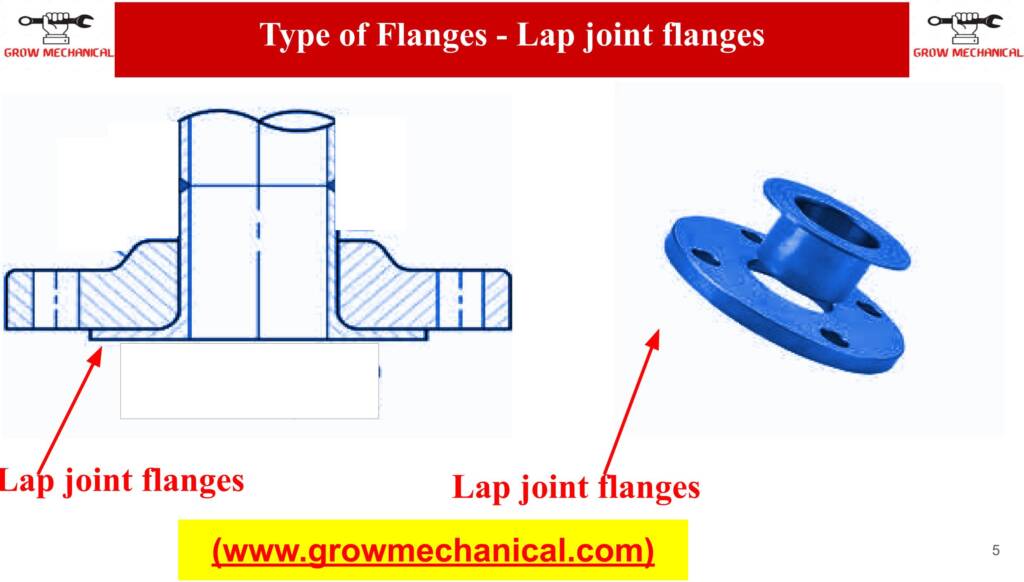

- LAP JOINT FLANGE

- SCREWED FLANGE

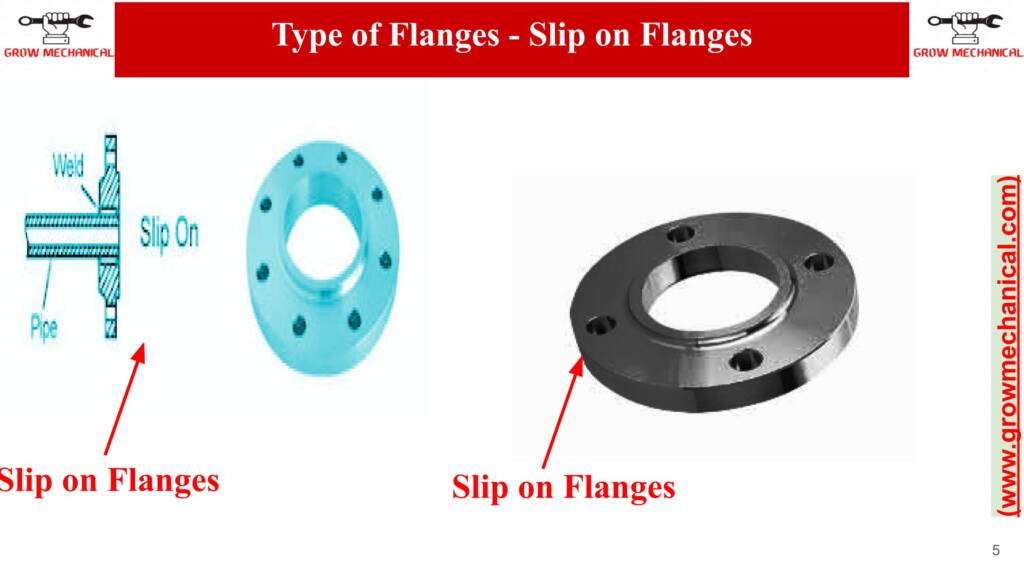

- SLIP ON FLANGE

- BLIND FLANGE

- SORF FLANGE