Maintenance Notifications

Welcome to the ultimate guide to different types of maintenance notifications! A maintenance professional, being informed about the various types of notifications is essential to ensure the smooth and efficient functioning of your equipment or property.

Understanding the different types of maintenance notifications, you’ll be able to stay on top of your maintenance schedules, reduce downtime, and avoid costly repairs. Whether you’re looking to optimize your maintenance processes or seeking to improve customer satisfaction by providing timely updates, this guide is a must-read. So, let’s dive in and discover the wide array of maintenance notifications that can benefit your organization and keep everything running smoothly.

Importance of maintenance notifications

Maintenance notifications play a crucial role in ensuring the longevity and efficiency of your equipment or property. Without proper notifications, you may overlook important maintenance tasks, leading to unexpected breakdowns and costly repairs.

One of the key benefits of maintenance notifications is that they help you stay organized and informed about upcoming maintenance activities. Scheduled maintenance notifications, for instance, allow you to plan and allocate resources effectively, ensuring that maintenance tasks are completed on time.

Moreover, maintenance notifications also serve as a reminder for preventive maintenance activities. By sending out reminders, you can proactively address potential issues before they escalate, extending the lifespan of your equipment and reducing the chance of unexpected breakdowns.

In addition to preventing downtime, maintenance notifications also contribute to a safer working environment. Emergency maintenance notifications, for example, alert employees or residents about potential hazards, allowing them to take necessary precautions and evacuate if needed.

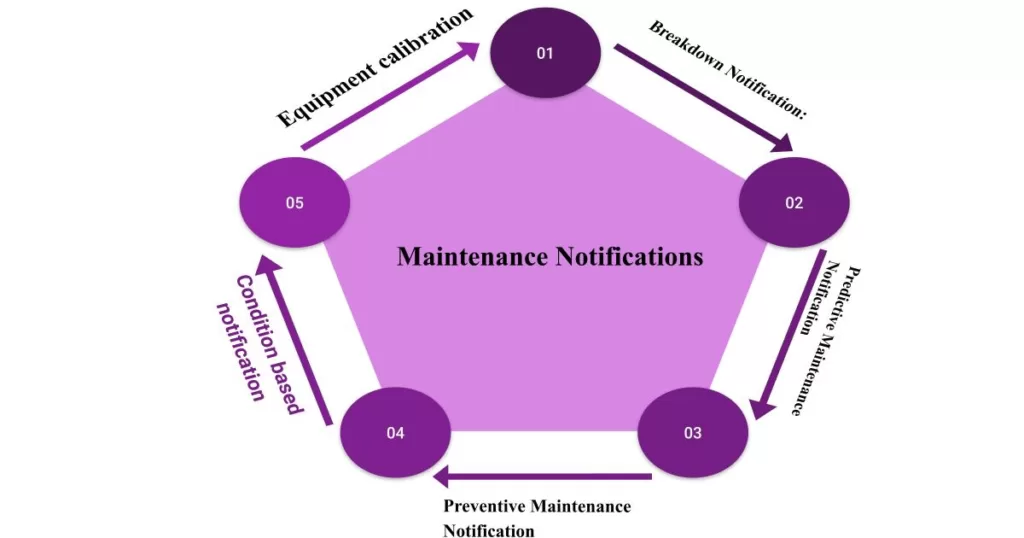

Types of maintenance notifications

Maintenance notifications can be categorized into different types based on their purpose and urgency. Let’s explore some of the most common types of maintenance notifications used in various industries.

| Notification Type | Reason | SAP Tcode |

|---|---|---|

| A1 | Equipment breakdown | IW21 |

| A2 | Preventive maintenance schedule | IW22 |

| A3 | Inspection required | IW23 |

| A4 | Corrective maintenance request | IW24 |

| A5 | Lubrication needed | IW25 |

| A6 | Equipment calibration | IW26 |

| A7 | Safety-related maintenance | IW27 |

maintenance notifications are used to communicate information about maintenance activities, report issues, and track the status of work orders. SAP (Systems, Applications, and Products) is a widely used enterprise resource planning (ERP) software that includes modules for managing various business functions, including maintenance. Here are some common types of maintenance notifications in a chemical plant and the corresponding SAP transaction codes (Tcodes) for creating, viewing, and changing them:

- Breakdown Notification:

- Tcode for creation: IW21 (Create Notification)

- Tcode for viewing: IW23 (Display Notification)

- Tcode for change: IW22 (Change Notification)

- Preventive Maintenance Notification:

- Tcode for creation: IW21 (Create Notification)

- Tcode for viewing: IW23 (Display Notification)

- Tcode for change: IW22 (Change Notification)

- Predictive Maintenance Notification:

- Tcode for creation: IW21 (Create Notification)

- Tcode for viewing: IW23 (Display Notification)

- Tcode for change: IW22 (Change Notification)

Create Predictive Maintenance Notification (Tcode: IW21):

- Enter Tcode IW21 in the SAP command field.

- Select the appropriate Notification type. For Predictive Maintenance, it might be PM01 – Breakdown Maintenance.

- Enter the relevant information such as Equipment, Functional Location, Notification Description, Priority, etc.

- In the “Tasks” tab, you may enter details related to the predictive maintenance task, such as the type of predictive maintenance, predicted date, and other relevant information.

- Save the notification.

View Predictive Maintenance Notification (Tcode: IW23):

- Enter Tcode IW23 in the SAP command field.

- Enter the Notification number or use other filter criteria to search for the relevant Predictive Maintenance Notification.

- Review the details of the notification, including the status, description, and predictive maintenance information.

Change Predictive Maintenance Notification (Tcode: IW22):

- Enter Tcode IW22 in the SAP command field.

- Enter the Notification number for the Predictive Maintenance Notification you want to change.

- Make the necessary modifications to the notification details, including predictive maintenance task information.

- Save the changes.

Please note that the specific fields and tabs for predictive maintenance tasks may be configured based on your organization’s needs and the version of SAP in use. Additionally, users need the appropriate authorizations to perform these actions in the SAP system.

Inspection required Notification:

Create Inspection Notification (IW21):

Transaction Code: IW21

- Steps:

- Enter Tcode IW21 in the SAP command field.

- Choose the appropriate notification type for inspection (e.g., Q1 – Inspection Request).

- Enter the relevant details, such as equipment, functional location, description of the inspection, priority, etc.

- Save the notification.

View Inspection Notification (IW23):

Transaction Code: IW23

Steps:

- Enter Tcode IW23 in the SAP command field.

- Enter the notification number or use filter criteria to find the inspection notification.

- Review the details of the inspection notification, including its status, description, and other relevant information.

Change Inspection Notification (IW22):

- Transaction Code: IW22

- Steps: Enter Tcode IW22 in the SAP command field.

- Enter the notification number of the inspection notification you want to change.

- Make the necessary modifications to the inspection notification details.

- Save the changes.

- Environmental Notification:

-

- Tcode for creation: IW21 (Create Notification)

- Tcode for viewing: IW23 (Display Notification)

- Tcode for change: IW22 (Change Notification)

- Steps for creating, viewing, and changing a notification in SAP:

- Creation (IW21):

- Enter Tcode IW21 in the SAP command field.

- Choose the appropriate notification type (e.g., Breakdown, Preventive, etc.).

- Enter the relevant information, such as equipment, functional location, description of the issue, priority, etc.

- Save the notification.

- Viewing (IW23):

- Enter Tcode IW23 in the SAP command field.

- Enter the notification number or filter criteria to find the relevant notification.

- Review the details of the notification, including status, description, and other relevant information.

- Change (IW22):

- Enter Tcode IW22 in the SAP command field.

- Enter the notification number you want to change.

- Make the necessary modifications to the notification details.

- Save the changes.

- It’s important to note that the specific steps and fields may vary based on the version of SAP and the configuration of the system in use. Users should have the necessary authorization to perform these actions in the SAP system. Additionally, the terminology and specific notification types may be customized to align with the plant’s requirements.

- Corrective maintenance request Notification:

- In SAP, Corrective Maintenance Requests are typically managed through Maintenance Notifications. Here are the SAP transaction codes (Tcodes) and steps for creating, viewing, and changing a Corrective Maintenance Notification:

- Create Corrective Maintenance Notification (IW21):

-

- Enter Tcode IW21 in the SAP command field.

- Select the appropriate notification type, usually “M1 – Breakdown Maintenance” for corrective maintenance.

- Fill in the required information such as equipment, functional location, description of the issue, priority, etc.

- Save the notification.

- View Corrective Maintenance Notification (IW23):

-

- Enter Tcode IW23 in the SAP command field.

- Enter the notification number or use other filter criteria to find the relevant notification.

- Review the details of the notification, including status, description, and other relevant information.

- Change Corrective Maintenance Notification (IW22):

-

- Enter Tcode IW22 in the SAP command field.

- Enter the notification number you want to change.

- Make the necessary modifications to the notification details.

- Save the changes.

- All most common Tcode for Plant maintenance

- In SAP, there are various transaction codes (Tcodes) related to maintenance across different modules. Here are some common maintenance-related Tcodes:

- Plant Maintenance (PM) Module:

-

- Create Notification: IW21

- Display Notification: IW23

- Change Notification: IW22

- Create Maintenance Order: IW31

- Display Maintenance Order: IW33

- Change Maintenance Order: IW32

- Goods Movement: MB1A

- Create Equipment Master Record: IE01

- Display Equipment Master Record: IE03

- Change Equipment Master Record: IE02

- Materials Management (MM) Module:

-

- Create Purchase Requisition: ME51N

- Display Purchase Requisition: ME53N

- Create Purchase Order: ME21N

- Display Purchase Order: ME23N

- Goods Receipt: MIGO

- Inventory Management (IM) Module:

-

- Display Stock/Requirements List: MMBE

- Material Document List: MB51

- Reservation List: MB25

- Controlling (CO) Module:

-

- Display Actual Line Items: KSB1

- Internal Order Master Data: KO02

- Asset Management (AM) Module:

-

- Create Asset Master Record: AS01

- Display Asset Master Record: AS03

- Change Asset Master Record: AS02

- Depreciation Posting: AFAB

- Quality Management (QM) Module:

-

- Create Inspection Lot: QA01

- Record Inspection Results: QA32

- Display Inspection Lot: QA03

- These Tcodes cover various aspects of maintenance, including creating and managing notifications, work orders, equipment master records, purchase requisitions/orders, goods movements, inventory, internal orders, asset management, and quality inspections.

- Keep in mind that the availability and functionality of these Tcodes may vary based on the SAP modules implemented in your system and the specific configuration of your SAP environment. It’s recommended to consult with your SAP system administrator or consultant for precise information tailored to your organization’s SAP setup.