What is the ASTM A106 standard?

ASTM A106 is used as a standard of seamless carbon steel pipe and tubes for high-temperature service, like steams 750 degrees F and others. ASTM A106 is equivalent to ASME SA106 or also called ASME SA106 as a second name. It is mostly used in refineries, chemical industries, and power plants when gasses or fluids are transferred at high temperatures and pressures services. This is covering three grades like ASTM A106 Grade A, ASTM A106 Grade B, ASTM A106 Grade C. ASTM’s full form is the American Society for Testing and Materials; it is an American standard. This standard is used in Indian boiler regulation (IBR) for piping systems and compiles all the requirements for the same. But before the start of fabrication work, you have to need to take approval from the IBR inspector if its services came in IBR.

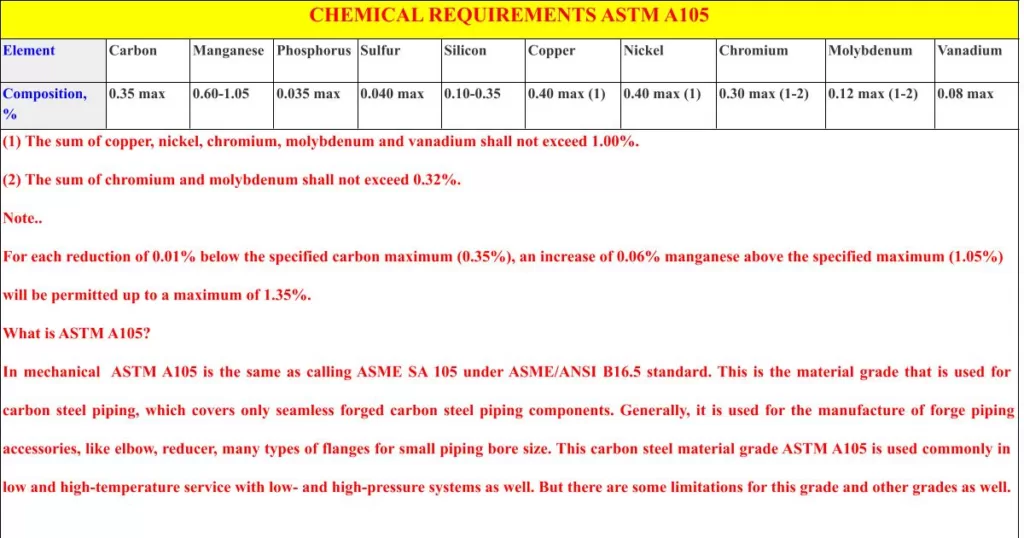

Chemical composition in % ASTM A106

Note- For any reduction of 0.01% below the specified carbon maximum, an increase of 0.06% of manganese above the specified maximum will be permitted up to a maximum of 1.35%.

Mechanical Properties of ASTM A106 for Grades A, B & C

We will delve into the mechanical properties of ASTM A106 for Grades A, B, and C. ASTM A106 is a specification that covers seamless carbon steel pipe for high-temperature service. Understanding the mechanical properties of different grades is crucial for selecting the appropriate material for your specific application. Read on to explore the key properties including tensile strength, yield strength, and impact properties.

- Tensile Strength: Tensile strength is a measure of a material’s resistance to breaking under tension. ASTM A106 Grade A has a minimum tensile strength of X MPa, Grade B has a minimum tensile strength of Y MPa, while Grade C has a minimum tensile strength of Z MPa. The higher the tensile strength, the stronger the material, providing greater structural integrity.

- Yield Strength: Yield strength refers to the maximum stress that a material can withstand before it starts to deform permanently. For ASTM A106, Grade A has a minimum yield strength of X MPa, Grade B has a minimum yield strength of Y MPa, and Grade C has a minimum yield strength of Z MPa. A higher yield strength indicates better resistance to deformation, making it suitable for demanding applications.

- Impact Properties: The impact properties of ASTM A106 grades are determined by conducting Charpy V-notch (CVN) impact tests. These tests measure the energy absorbed by the material when subjected to an impact load. Grade A, B, and C exhibit different impact properties, with each grade having its minimum requirements. The impact properties are critical for applications subjected to low temperatures or dynamic loading conditions.

- Other Mechanical Properties: Apart from tensile strength, yield strength, and impact properties, there are other relevant mechanical properties to consider, such as elongation, hardness, and bend testing. These properties help assess the material’s ductility, resistance to deformation, and formability, ensuring it meets the specific requirements of your project.

Conclusion:

Understanding the mechanical properties of ASTM A106 Grades A, B, and C is essential for making informed decisions when selecting carbon steel pipes for high-temperature service. The tensile strength, yield strength, and impact properties vary between these grades, allowing for tailored applications in different industries. By considering these properties alongside other factors, such as corrosion resistance and chemical composition, you can confidently choose the appropriate ASTM A106 grade for your project’s requirements.

What is the meaning of Grades A, B, and C?

Grades A, B, and C in ASTM A106:

Grade A: ASTM A106 Grade A pipes are the least commonly used within the A106 specification. They have a minimum tensile strength of 48,000 psi (330 MPa) and a minimum yield strength of 30,000 psi (205 MPa). Grade A pipes are typically used for low-pressure and low-temperature applications.

Grade B: ASTM A106 Grade B is the most common grade used in the A106 specification. It offers higher tensile strength compared to Grade A, with a minimum of 60,000 psi (415 MPa), and higher yield strength, with a minimum of 35,000 psi (240 MPa). Grade B pipes find extensive usage in various industries due to their versatility and durability.

Grade C: ASTM A106 Grade C pipes possess similar mechanical properties to Grade B pipes, but with slightly lower tensile and yield strength. Grade C has a minimum tensile strength of 70,000 psi (485 MPa) and a minimum yield strength of 40,000 psi (275 MPa). These pipes are often selected for applications requiring higher working pressures.

Conclusion:

ASTM A106 is a critical standard governing the manufacturing and use of seamless carbon steel pipes in high-temperature services. Understanding the distinctions between Grades A, B, and C is essential for professionals working with these pipes. While Grade A is suitable for low-pressure and low-temperature applications, Grade B is the most commonly used grade. Grade C, on the other hand, is chosen when higher working pressures are required. By comprehending the meaning of these grades, industry experts can make informed decisions regarding the selection and application of ASTM A106 pipes.

Specification of ASTM A106 Grades A, B, and C

The higher-grade material that ASTM A106 receives, the strength of that grade pipe is also higher in the sense of strength compression C>B>A.

ASTM A106 Grade A

Grade A, is used as softer steel, which means it is easy to bend. A indicates a ferrous metal it is recommended for use in close coiling and cold bending applications. ASTM A106 Grade A piping available in size range .5 inches to 36 inches. The strength of Pipe grade A is less than grade B & grade C.

ASTM A106 Grade B

ASTM A106 Grade B pipe materials bear higher stress than grade A and the strength of Pipe grade B material is less than grade C but higher than grade A. This is most common of grade use in industries and compared to other due it is almost appropriate to grade C. but less expensive than grade C pipe. This is mainly suited for machining operations and uses for the same

ASTM A106 Grade C

Understanding ASTM A106 Grade C: Properties, Applications, and Specifications

ASTM A106 Grade C is a widely used carbon steel pipe specification that is known for its high temperature and pressure resistance. This article aims to provide a comprehensive overview of ASTM A106 Grade C, including its properties, applications, and specifications.

What is ASTM A106 Grade C?

ASTM A106 Grade C is a seamless carbon steel pipe specification used for high-temperature service. It is specifically designed to withstand high-pressure conditions and is suitable for various industrial applications. This grade offers excellent weldability and can be used in both bending and flanging operations.

Properties of ASTM A106 Grade C:

Chemical Composition: ASTM A106 Grade C has a carbon content ranging from 0.25% to 0.35%, manganese content of 0.29% to 1.06%, phosphorus content of 0.035% maximum, sulfur content of 0.035% maximum, and silicon content of 0.10% minimum.

Mechanical Properties: The minimum tensile strength of ASTM A106 Grade C is 70,000 psi (485 MPa) and the minimum yield strength is 40,000 psi (275 MPa). It has a maximum hardness of 79 HRB (Rockwell B).

Applications of ASTM A106 Grade C:

- High-Temperature Service: ASTM A106 Grade C pipes are commonly used for transporting fluids and gases at high temperatures and pressures in various industries such as oil and gas, power generation, chemical processing, and more.

- Boiler Tubes: Due to its excellent high-temperature resistance, ASTM A106 Grade C is frequently used in boiler tubes for power plants and industrial boilers.

- Heat Exchangers: The grade is suitable for heat exchangers that operate at high temperatures, ensuring efficient heat transfer and long-lasting performance.

- Refineries and Petrochemical Plants: ASTM A106 Grade C is widely utilized in refineries and petrochemical plants for the transportation of petroleum products and process fluids.

Specifications and Standards:

- ASTM A106: This specification covers seamless carbon steel pipes for high-temperature service. It includes various grades, with Grade C being one of the commonly used grades.

- ASME B36.10M: This standard provides the dimensions and weights of seamless and welded steel pipes, including ASTM A106 Grade C.

- API 5L: While not specific to ASTM A106 Grade C, API 5L is a widely used standard for steel pipe manufacturing and can be applicable to Grade C pipes.

Conclusion:

ASTM A106 Grade C is a reliable and versatile carbon steel pipe grade suitable for high-temperature and high-pressure applications. Its excellent mechanical properties and weldability make it a preferred choice for industries requiring durable and efficient piping systems. By meeting rigorous specifications and standards, ASTM A106 Grade C provides reliable performance and is widely used across various sectors, including oil and gas, power generation, and chemical processing.

What kind of welding can be used in ASTM a106 Grade B?

ASTM A106 Grade B is a widely used specification for seamless carbon steel pipe that is suitable for high-temperature service. Welding is an essential process in the fabrication of ASTM A106 Grade B pipes, ensuring their structural integrity and performance. In this article, we will delve into the various welding techniques that can be employed for ASTM A106 Grade B and explore their benefits and considerations.

Shielded Metal Arc Welding (SMAW):

Shielded Metal Arc Welding, commonly known as stick welding, is a versatile and widely utilized welding technique for ASTM A106 Grade B pipes. SMAW employs a consumable electrode coated in flux, which creates a shield to protect the weld from atmospheric contamination. This technique offers excellent control and can be used for welding in various positions. SMAW is suitable for both field and shop applications, making it a preferred choice in many scenarios.

Gas Tungsten Arc Welding (GTAW):

Gas Tungsten Arc Welding, also known as TIG (Tungsten Inert Gas) welding, is another popular method for joining ASTM A106 Grade B pipes. GTAW employs a non-consumable tungsten electrode to create an arc and a shielding gas, typically argon, to protect the weld zone. This technique offers precise control, producing high-quality welds with minimal spatter. GTAW is particularly suitable for thin-walled pipes and applications that require a superior aesthetic finish.

Gas Metal Arc Welding (GMAW):

Gas Metal Arc Welding, commonly known as MIG (Metal Inert Gas) welding, is a semi-automatic welding technique that utilizes a consumable wire electrode and a shielding gas. GMAW is known for its high welding speed and versatility, making it an efficient choice for joining ASTM A106 Grade B pipes in various positions. However, it is essential to ensure proper gas selection and parameter settings to avoid issues like porosity and lack of fusion.

Flux-Cored Arc Welding (FCAW):

Flux-Cored Arc Welding is a versatile technique that combines elements of both SMAW and GMAW. FCAW employs a tubular wire electrode filled with flux, which provides a shielding gas and produces slag to protect the weld. This technique offers high deposition rates and deeper penetration, making it suitable for thicker-walled pipes. FCAW can be used in all positions and is particularly useful for field welding applications.

Considerations for Welding ASTM A106 Grade B Pipes:

- Preheating and Post-Weld Heat Treatment: Depending on the pipe thickness and intended service conditions, preheating and post-weld heat treatment may be required to prevent cracking and improve the mechanical properties of the weld.

- Welding Procedure Qualification: It is essential to follow the appropriate welding procedure specifications and conduct qualification tests to ensure the compatibility of the welding process with ASTM A106 Grade B.

- Material Selection: Choosing the correct filler metal that matches the base metal’s chemical composition is crucial to maintain the desired mechanical properties of the weld joint.

Conclusion:

When welding ASTM A106 Grade B pipes, various techniques such as Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW) can be employed. Each technique offers unique advantages and considerations, depending on the application requirements. Adhering to proper welding procedures, material selection, and post-weld treatments will ensure the integrity and performance of the welded joints in ASTM A106 Grade B pipes.

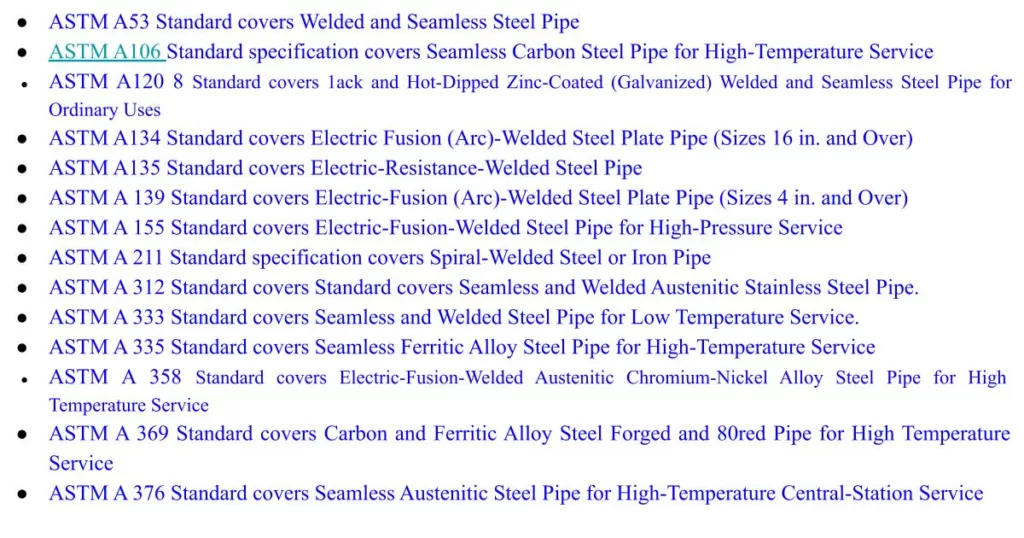

SOME OF THE IMPORTANT LING ARE HERE YOU CAN READ IT BY CLICKING ON TEXT.

- Great application of butterfly valve – API 609

- What is a globe valve and its uses part 1

- Basic application of gate valve part 1

- Types of valve

- Top 10 interview question answer glove valve

- Troubleshooting of the Piston valve part 1

- What is ASTM A105 grade