Introduction of ASTM A234 / ASTM A234M

Under ASTM A234 specification covers wrought carbon steel and alloy steel fittings of seamless and welded fitting materials. Design, dimension, tolerance, testing will be followed in ASME B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, and MSS-SP-97. These fittings are only applicable for pressure piping and vessel fabrication for service at moderate and high temperatures, and expressed in both unit inch-pound and in SI units.

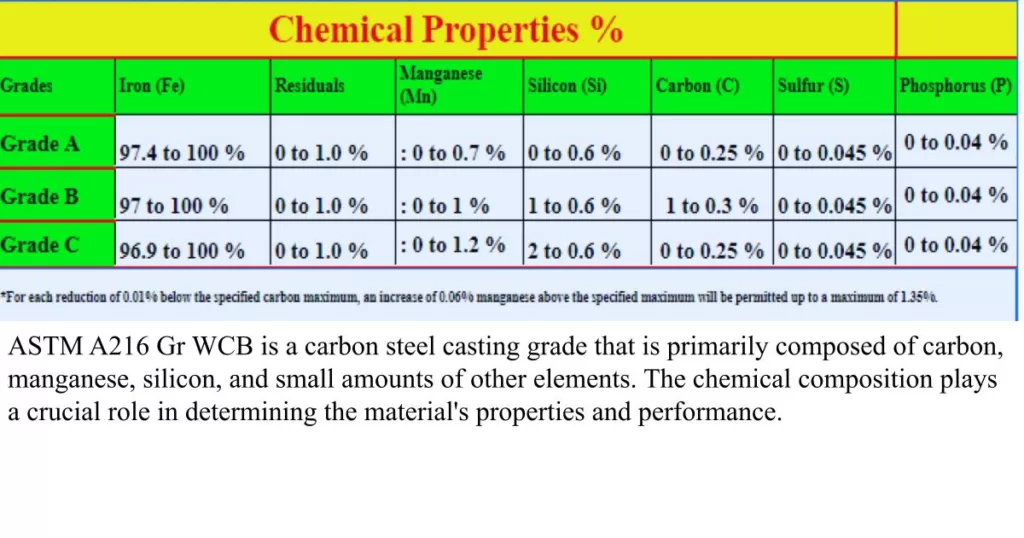

But this specification does not cover cast welding fittings and castings machined fittings. Both types will be governed by Specifications A 216/A 216M and A 217/ A 217M.

Materials Grade ASTM A234 / ASTM A234M

ASTM A234 Grade and WPC, WP11 WP11 CL1, WP11 CL3, Marking WP22 CL1, WPB WP22 CL3, WP1 Symbol WPR CL2, WP91 WP5 CL1, WP911 WP2 CL3, WP12 CL2 WP9 CL1 WP9 CL3.

In this standard it covers the specification of elbows, tees, reducers, caps and cross, it is usually used for butt weld. The fittings material within this standard specification consists of killed steel, forgings, fusion-welded tubular products, bars, plates, or seamless with filler metal added. ASTM A234 WPC that forms good connections between multiple pipes of various sizes. WPC Pipe, Elbow include other types of conventional and customized fittings. This specification covers Alloy Steel fittings of welded and seamless material construction, for use in the pressure piping and pressure vessel fabrication for operations at moderate to elevated temperatures.

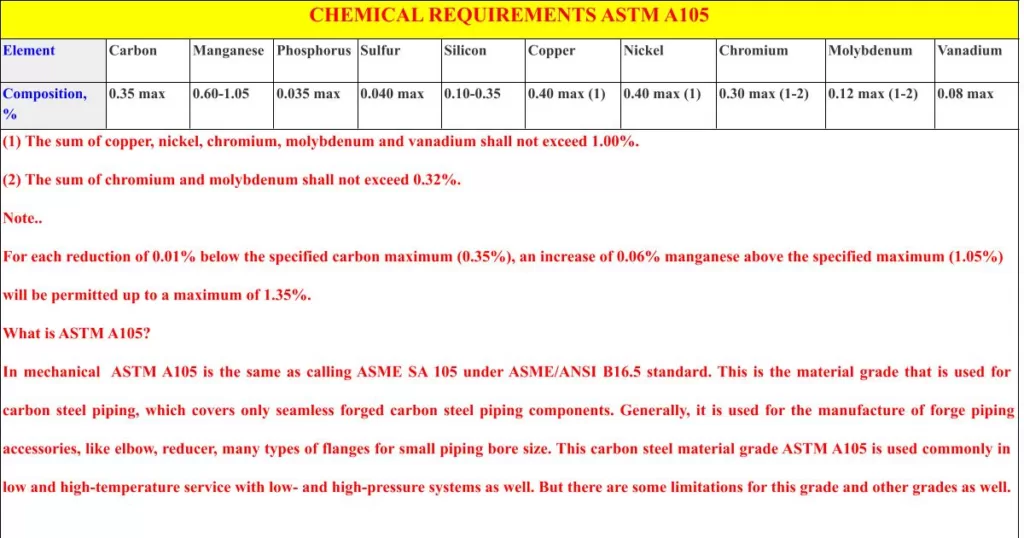

Chamical composition chart in %

Carbon Steel A234 WPC Buttweld Fittings are indispensable to the oil and petroleum industry. These type of pipes do’nt support porosity as they are formed through a single metal body and can be trusted for critical transmission cases. Besides, ASTM A234 Carbon Steel WPC Lap Joint Stub Ends which are reusable and corrosion resistant, divide quick dismantling in the case of inspection. Also a wide range of Carbon Steel ASTM A234 WPC pipe fittings such as Carbon Steel WPC tee, WPC Carbon End Pipe Cap, ASTM A234 WPC reducer, A234 WPC cross, Carbon Steel A234 WPC elbow, Carbon Steel WPC stub ends etc.

The important Specification For Carbon Steel ASTM A234 WPC Pipe Fittings

Specifications : ASTM A234 / ASME SA234M

Dimensions : ASME/ANSI B16.9/ ANSI B16.11/ MSS-SP-79, MSS-SP-83, MSS-SP-95, and MSS-SP-97

Size : 1/8” NB TO 48” NB. (Seamless & Welded, Fabricated)

Fabricated Type Available : Seamless / Welded / Fabricated

Elbow Bending Radius : R=1D, 45, 1.5D (90), 2D, 3D, 5D, 6D, 8D, 10D or Custom.

Pipe Thickness measure in : Schedule number 5s, Sch 10s, Schedule 40s, Schedule 80s, Schedule 160s, Schedule XXS or Custom Thickness.

Tensile Strength 60,000 pis 415 Mpa, Yield Strength 35,000 psi 240 Mpa

Pressure Ratings: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2000 LBS, 3000 LBS to 9000 LBS.

In these standard Grade WPB is the most common material used for medium and high temperature pipelines. W means weldable, P means pressure, B is grade b, refer to the minimum yield strength.

You can check the following article as well…….