Bearing

The term bearing comes from the bear, a bearing is a component that supports load while permitting relative motion between two parts of the machine. Bearing is an important part of a machine that carries the load, reduces friction, and gives a smooth operation. The selection of bearings is based on the requirement of the operating load for a given period of the equipment. Centrifugal pump

Type of bearing

- Rolling contact bearing

- Plain bearing (sleeve bearing)

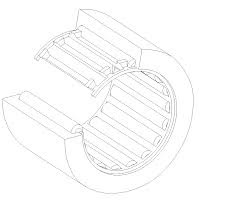

Rolling element bearing

A rolling-element bearing carries load between two parts by placing the circular element between the inner and outer race of the bearing. Rolling contact bearings are designed to carry a high radial and high axial load, or a combination of both. Many types of circular elements are used in rolling element bearings like balls, spherical roller, needle roller, taper roller, circular bearing. Rolling contact bearings are divided into two categories.

Types of rolling contact bearing

- Ball-bearing

- Roller bearing

But these two types of bearing are divided in many parts, later we will discuss in detail. There are a variety of rolling contact bearings available in the industry.

Types of ball bearing

Ball bearings are classified into three types

- Deep groove ball bearing

- Angular contact ball bearing

- Self-aligning ball bearing

To get deep knowledge of any type of bearing, you have to learn about construction, application, and features.

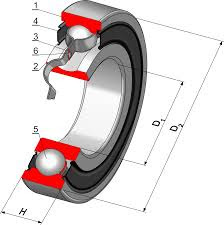

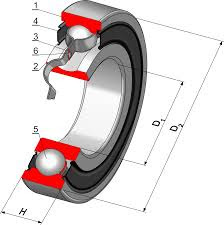

Deep groove ball bearing

Deep groove ball bearings run with very low friction because of the point contact between balls, inner race and outer race. It has less noise due to being pre-loaded during installation. Very little misalignment is tolerated between the inner and outer races of bearing. Axial movement is not permitted, this type of bearing can not be used as a floating type.

Applications

Applications

- Motorcycles and other types of low weight vehicles

- Small and medium-duty electric motor, and electric fans.

- Convener systems and small size or light duty gearboxes.

- Low duty machinery tools like torquing tools

- Low and medium-duty pumps.

Angular contact ball bearing

Angular contact ball bearings are constructed with axially asymmetric races and able to bear higher thrust and radial load, while higher contact angles are kept around 40 degrees. Angular contact ball bearing can take the radial load with high axial load, it is also used for combined load application. It may be used in pairs in “O”, which is back to back arrangement, ‘X’ for face-to-face arrangement, and tandem arrangement. It can run at high speed, high accuracy with low noise. But axial displacement is not possible in it and it does not compensate for misalignment.

Applications

- High-speed application

- Gearboxes

- Clutch system

- Motorcycle overhead system

- Mills

- Wind energy

- Steel plants

What is the nominal angle for angular contact bearing?

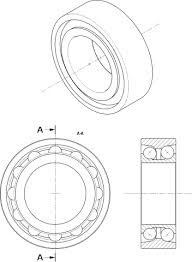

Self-aligning ball bearing

It consists of two rows for the ball with a common spherical outer race, and a cage is between the inner and outer race of the bearing. In the self-aligning ball-bearing, the inner ring has two raceways. The self-aligning ball bearing is recommended when the machine shaft can be bent during operation and housing deformation, or the alignment between shaft and housing is difficult, and it creates less friction than other types of bearing. This type of bearing with the taper bore that’s why it easily fits in the shaft with the adapter assembly.

Application

- Textile

- Mining

- Heavy machinery

- Power machinery

- Agriculture

- Liquid ring compressor

Types of roller bearing

- Cylindrical roller bearing

- Spherical roller bearing

- Needle roller bearing

- Taper roller bearing

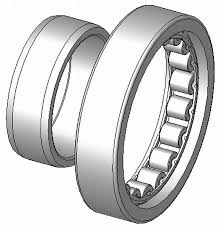

Cylindrical roller bearing

there are many types of cylindrical roller bearing are used. but single row cylindrical roller bearings are mostly used, cylindrical roller bearing takes more space as compared to another type of bearing during installation.

single row cylindrical (B.) have radial load carrying capacity is less. But double or multi-row cylindrical roller bearings is used for carrying the heavy radial load.

Application

Application

- In power generation

- Oil field

- Heavy-duty gearbox

- Machine tools transmission

- Vibration machine

- Trains wheels

- And other types of heavy redial loads machinery.

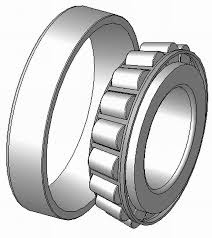

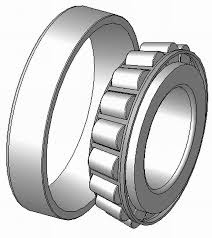

Taper roller bearing

It is constructed with taper inner and outer raceways. The inner and outer ring is separated by the tapered roller it is used in tight-fitting arrangement. When used in pairs arrangement, proper internal clearances and preload can be set by adjusting the distance between two bearing inner and outer rings. Designed to accumulate the combined load, the axial load carrying capacity of the bearing depends on the contact angle between the raceway and rollers. It means that the larger the contact angle, the capacity to bear the axial load is large (heavy).

Applications

Applications

- Mostly used for combined load

- It is used in face-to-face, back-to-back, or in tandem

- Gearbox

- Overhead hoisting equipment

- Mining equipment

- Rolling mills

Spherical roller bearing

It is a type of rolling-element bearing and used for heavy heavy radial and axial load applications. It can bear more angular misalignment as compared to others. Spherical roller bearing consists of the outer ring having a continuous spherical raceway. Within that spherical race, two rows of barrel-shaped rollers are operated.

This barrel-shaped roller is intended to be guided by an inner ring raceway. But misalignment and shaft deflection is a big challenge for Spherical roller bearing because it can not bear more misalignment and shaft deflection to prevent this type of problem used with the combination of spherical roller bearing. The spherical roller bearing is used in two combinations. single row spherical roller bearing, and double Spherical roller bearing as per required application.

Application

- Use in equipment for shock resistance

- Use for bear heavy load due to it ring arrangement

- Heavy gearbox

- Turbine

- Compressor and mining equipment

- Mechanical fan

- Construction equipment

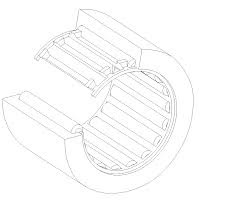

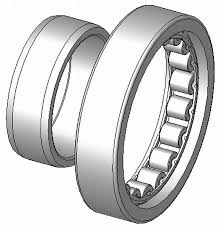

Needle roller bearing

This is a type of roller bearing. In this type of bearing very thin cylindrical rollers are used. The number of rollers used in this bearing is more than other types of roller bearing, so the radial load carrying capacity is also more. It is used as an interchange of sliding bearings. The needle roller bearing is available in many types of arrangements, like single row, double row, and split case.

Application

Application

- Rocker arm pivot

- Power transmission

- Pump

- Compressor

Some good article is here please read

Application

Application

Applications

Applications

Application

Application