What is a Sockolet used for?

Sockolet is used for 90 degree self-reinforcing branch accessories for pipe line fitting. As its names represent how that will connect to the run pipe (header pipe). Sockolet is a type of self-reinforced branch fitting developed by a company called Bonney Forge. And this is suitable for small bore branch connection pipes up to 1.5 inches.

This is available in 02 varieties, these are full size or reduced size. It is used in small bore pipe branch connections. That is similar to the weldolet but its branch connection is socket weld type. Another measure of changes is that weldolets are used for big bore branch connections as well but same designs as threadolets branch connections. Only types of connection changes that mean sockolet have come with socket weld joints whereas threadolets come with thread type connection.

How to select a sockolets

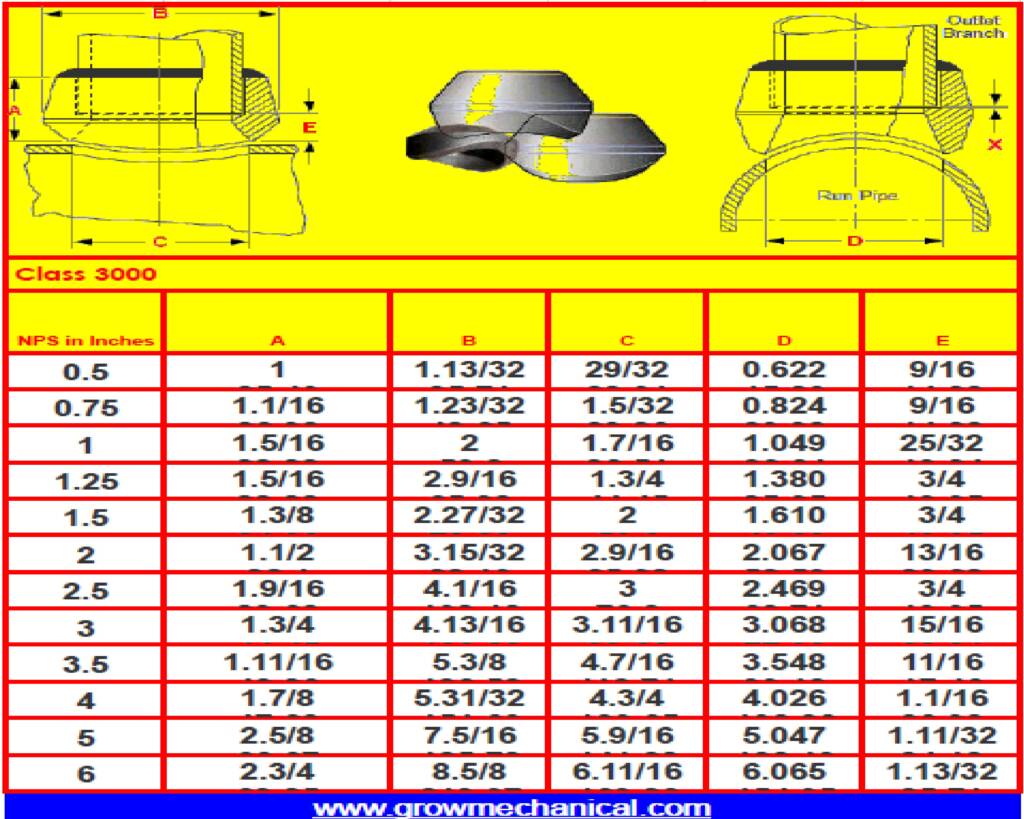

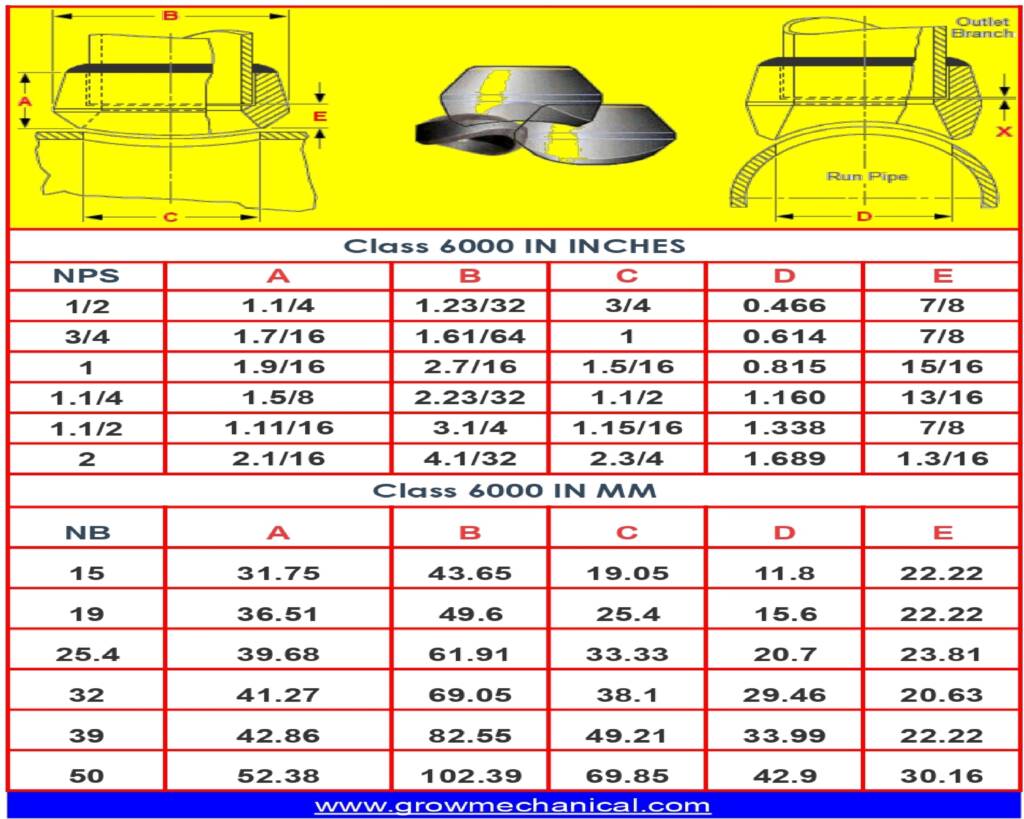

Bore size(mm) – (Run pipe size to branch pipe size) for example 100X15 , select your pipe line system pressure class/rating/schedule pipe (where it is to be used) – for example CL 3000, SCH 80, Which type of Olets are required – Sockolets or weldolets , threadolets or other. What types of end connection are required – like as Socketweld, which materials are to be used – CS/MS/SS/or other as per your requirements you can choose, which dimension standard to be used – like MSS SP97 or other, and last which design standard to be used – like ASTM A105 or other. These pipe fittings are designated as Class CL-2000/3000/6000 for threaded end pipe fittings and Class 3000, 6000, and 9000 for socket-weld end fittings.

These are important data required to select the olets. Socket Dimension should be as per ASME B16.11. MSS-SP-97 design standard used for 90° self-reinforced branch connection with butt, socket, and threaded end connection types.

Difference between Sockolet and a Weldolet

Sockolet and Weldolet are two types of branch connections that are used in piping systems. While both are designed to make a branch connection to a larger pipe, there are some key differences between the two:

- Weldolet is a cost-effective option for small branch connections, while Sockolet is a preferred choice for larger branch connections where high strength and durability are required.

- Weldolet is a welded fitting that is welded directly onto the run pipe, while Sockolet is a forged fitting that is connected to the run pipe with a socket weld.

- Weldolet is available in a variety of materials such as carbon steel, stainless steel, and alloy steel, while Sockolet is typically made of forged steel.

- Weldolet is a standard pipe fitting that conforms to the ASME B16.9 and MSS-SP-97 specifications, while Sockolet conforms to the MSS-SP-97 specification.

- Weldolet is typically used for smaller branch connections, while Sockolet is used for larger branch connections.

Weldolet has a higher pressure rating than Sockolet.

In summary, the main difference between Sockolet and Weldolet is their method of connection and their suitability for different sizes of branch connections. Weldolet is a welded fitting that is cost-effective for small branch connections, while Sockolet is a forged fitting that is preferred for larger branch connections requiring high strength and durability.

Sockolet

- Sockolet available in classes 3000#, 6000# and 9000#.

- Butt weld ends connection shall comply to ASME B16.25.

- Sockolets belong to the socket fittings and socket weld categories.

- Sockolets are used for less bore pipes applications, and smaller pipe diameters, than Weldolets less than 1.5 inches.

Weldolet

- whereas Weldolets are butt weld fittings.

- weldolets available in classes like 150, 300, 600, 900, and others.

- socket weld and threaded ends connection shall be comply ASME B16.11.

- Weldolets are most preferred used for big bore pipes applications, greater than 1.5 inches.

How to select Sockolets

When selecting a Sockolet for a piping system, there are several factors to consider in order to ensure that the fitting is compatible with the system and performs as intended. Some key selection points for Sockolet are:

- Size: The Sockolet should be selected based on the size of the run pipe and the size of the branch pipe. It is important to ensure that the Sockolet has the appropriate dimensions to fit both pipes.

- Material: Sockolets are typically made of forged steel, but the specific material selected will depend on the requirements of the system. Factors such as pressure, temperature, and corrosion resistance should be taken into account when selecting the material.

- Pressure rating: Sockolets are available in different pressure ratings, which should be matched to the pressure rating of the system.

- Standard specification: The Sockolet should conform to the appropriate standard specification, such as MSS-SP-97, to ensure compatibility with the system.

- Weldability: The Sockolet should be selected based on its weldability with the run pipe material to ensure a strong and reliable connection.

- Application: The Sockolet should be selected based on the specific application in which it will be used, such as high-temperature or high-pressure applications.

- Manufacturer: The Sockolet should be sourced from a reputable manufacturer with a proven track record of producing high-quality fittings.

By considering these selection points, it is possible to select a Sockolet that is compatible with the piping system and will perform as intended, providing reliable and long-lasting service.