Materials of Construction – (MOC)

The selection of material of construction for plant’s equipment, fitting, composite fitting like (elbow, tee, reducer, pipes, flange, orifice, valve, steam traps, NRV) etc. play a crucial role to sustain, reliable and life of itself. That must be based on various factors for setup a process plant. There are a variety of material and construction options available to consider. For some specific plants application itself dictates which MOCs are needed based on your previous experience, continuity and plant.

Now days some common materials are used for process plants such as carbon steel, stainless steel, alloy steel, graphite, glass, titanium, plastic (PVC), PTFE, Monel, Inconal etc.

All these materials of construction should be selected based on the following factors.

- Fluid Nature : corrosiveness, toxicity, flammability, viscosity.

- Service pressure and temperature.

- Expected operating life & availability.

- Fabrication method : Forging, casting and from plates.

- Environment (Desert, Temperate, Marine)

- Price (Economy)

There are some other factors such as compatibility of material of construction with existing plant operating conditions, ease of maintenance, and cleaning requirements to name a few.

Selection Criteria

- Big bore (diameters) flanged valves and components are manufactured by Casting.

- Small bore (diameters) flanged valves, socket welded and threaded components are mostly manufactured forged.

- Components like spectacle blind, Strainers etc. are made using plates.

- Materials are selected based on their mechanical properties and chemical properties.

- Mechanical properties: strength, ductility, hardness, brittleness, toughness

- Metallurgical properties: Chemical composition, weldability.

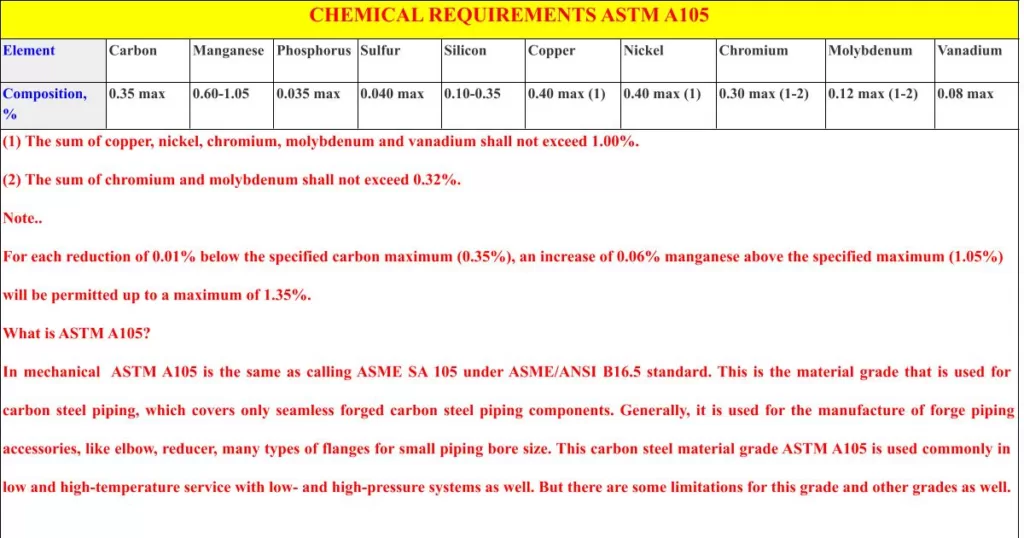

- Carbon increases the strength of steel but decreases weldability.

- Carbon steel used in piping has carbon content from 0.15% to 0.30%.

Now days there are various categories of steel available. Based on the chemical compositions.

Steel is divided into four basic groups:

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Tool Steel

Lists of Piping Materials

Pipe line materials generally include Pipes, Fittings, Valves, steam traps, strainers, filters, PSV, PRV etc. Here is a list of ASTM materials used for manufacturing of various piping parts and its components.

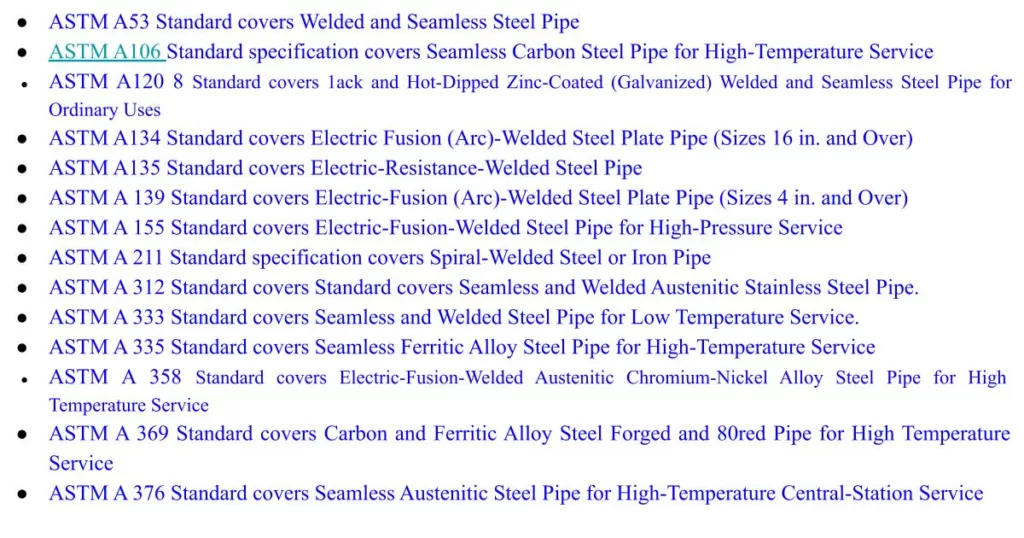

The American Society for Testing and Materials (ASTM) has developed, researched and defined many types of material standards for plants and industry. Properties of these materials depend on chemical composition of services fluids, design temperatures and pressure as well as method of manufacture of pipe fittings. Pipes in the oil and gas industry are made either with a seamless process or using plates and welding process. Below mentioned list of such ASTM Standard materials designed for manufacture of pipes by seamless and welding process.

- ASTM A53 Standard covers Welded and Seamless Steel Pipe

- ASTM A106 Standard specification covers Seamless Carbon Steel Pipe for High-Temperature Service

- ASTM A120 8 Standard covers 1ack and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Ordinary Uses

- ASTM A134 Standard covers Electric Fusion (Arc)-Welded Steel Plate Pipe (Sizes 16 in. and Over)

- ASTM A135 Standard covers Electric-Resistance-Welded Steel Pipe

- ASTM A 139 Standard covers Electric-Fusion (Arc)-Welded Steel Plate Pipe (Sizes 4 in. and Over)

- ASTM A 155 Standard covers Electric-Fusion-Welded Steel Pipe for High-Pressure Service

- ASTM A 211 Standard specification covers Spiral-Welded Steel or Iron Pipe

- ASTM A 312 Standard covers Standard covers Seamless and Welded Austenitic Stainless Steel Pipe.

- ASTM A 333 Standard covers Seamless and Welded Steel Pipe for Low Temperature Service.

- ASTM A 335 Standard covers Seamless Ferritic Alloy Steel Pipe for High-Temperature Service

- ASTM A 358 Standard covers Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy Steel Pipe for High Temperature Service

- ASTM A 369 Standard covers Carbon and Ferritic Alloy Steel Forged and 80red Pipe for High Temperature Service

- ASTM A 376 Standard covers Seamless Austenitic Steel Pipe for High-Temperature Central-Station Service

- ASTM A 381 Standard covers Metal-Arc-Welded Steel Pipe for High-Pressure Transmission Systems

- ASTM A 405 Standard covers Seamless Ferritic Alloy Steel Pipe Specially Heat Treated for High Temperature Service

- ASTM A 523 Standard covers Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High Pressure Pipe-Type Cable Circuits

- ASTM A 524 Standard covers Seamless Carbon Steel Pipe for Process Piping

- ASTM A 530 Standard covers General Requirements for Specialized Carbon and Alloy Steel Pipe

- API-5L Standard covers Line Pipe

- API-5LX Standard covers High-Test Line Pipe

- API-5LS Standard covers Spiral Weld Line Pipe