What is Latrolet fitting?

Latrolet is a type of self-reinforcing branch fitting accessories for pipe-line. As its names represent how that will connect to the run pipe (header pipe). Latrolet fitting was developed by a company called Bonney Forge. And this is mostly suitable for small bore branch connection pipes. A Latrolet is available in 45° outlet fittings and in some other cases other degrees are also available as per user requirements. These outlets come in several different standards, thickness and size etc. These are mostly used for low-pressure pipe branch connections. This is used as Tee fitting but very smaller and lightweight, cheaper than Tees. The biggest advantages of Letrolets fitting is that end connections can be butt welded, socket welded or threaded. That is similar to the sockolets and Weldolet but its branch connection are changes only.

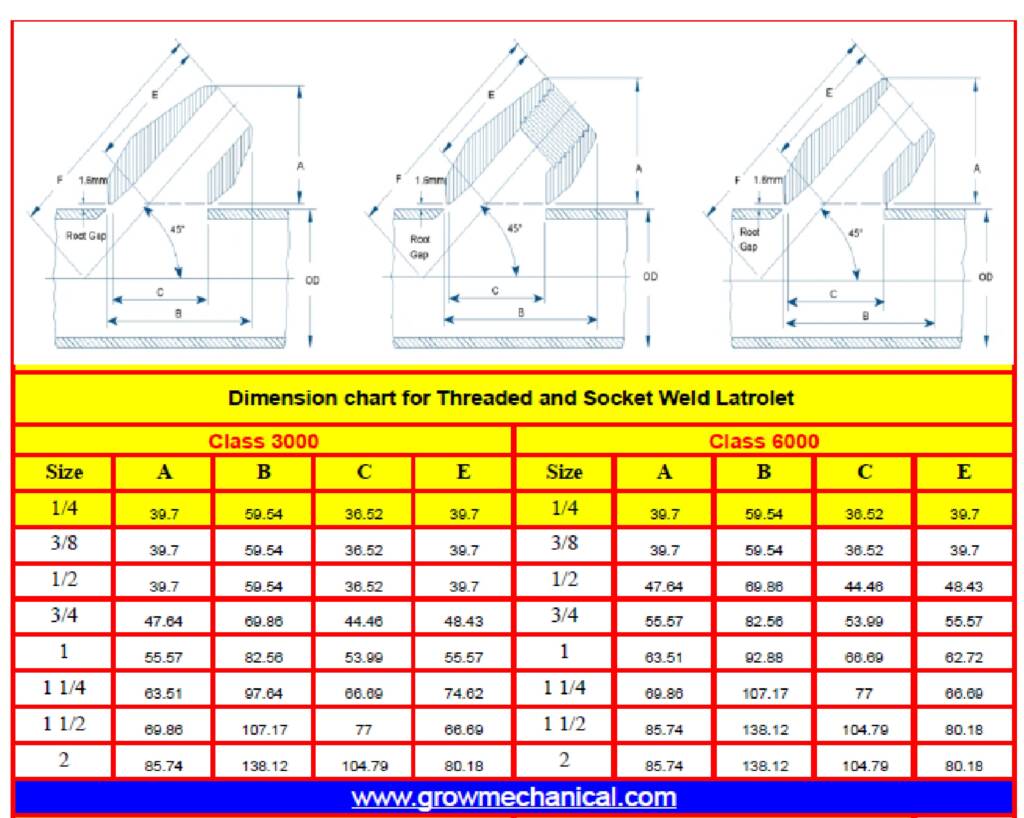

Latrolet Dimensions standard : ASME 16.11, MSS SP-97, BS 3799.

Avalible Pressure Class : 3000, 6000, & 9000 LBS.

Its threads are generally of the NPT (National Pipe Thread) type and conform to the ASME B1.20.1 specification.

Standard and Code

Most common types of Standard and Code are used nowadays to manufacture Letrolets.

ASTM A182 (ASME SA182) Standard/ Code used for Specification for Wrought Austenitic Stainless Steel Piping Fittings

ASME B16.11 Standard/ Code used for Forged Fittings Socket (Welding and Threaded)

MSS SP-97 Standard/ Code used for Integrally Reinforced Forged Branch Latrolet – Socket Welding, Threaded and Buttwelding End.

Manufacturing grads

There are some of the most common types of materials grades given below.

- For Carbon Steel materials grades ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3.

- For Alloy Steel materials grades ASTM A182 F1, F5, F9, F11, F12, F22, F9.

- For Stainless Steel materials grades ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321.

Inspection

There are some inspection points given to inspect and Letrolet fitting.

- Surface of the Letrolet body free from dents, die marks, porosity, undercuts etc.

- Match the marking on the olets Such as Size, Material Code, Grade, Thickness, Heat No and Measure dimensions of latrolet Such as diameter, wall thickness, and end to end length should be as standard.

Remark(s) of Growmechanical

Try the site of Bonney Forge . Weldolet, Sockolet, Thredolet, Latrolet, Elbolet, Nipolet, Sweepolet, Brazolet, Coupolet are trademarks registered ® for the exclusive use of Bonney Forge.