Shaft Coupling

Shaft coupling is a mechanical element which is in two halves and that is used to connect the two different machines. These mechanics may pump and motor, pump and turbine, pump and gearbox and motor as per use requirement. Its selection plays a very important role for equipment reliability and availability for operation. Now we will see how to select an appropriate coupling depend on its application and criteria

How To Select Shaft Coupling?

To select appropriate coupling for your equipment, you should have required the following details about both machines: Driver and driven machines, and these details are.

- What is Application.

- Which types of machines need to connect?

- Operating RPM of your machine

- Required torque to drive the driven machine (It is dependent on many factors, like viscosity, fluid nature and load)

- Operating hours for equipment

- Select types for coupling according to application

- Motor rating or your driver equipment ratings in the form of kilowatts and RPM

- Check the diameter of both machine shafts where the coupling hub will be installed.

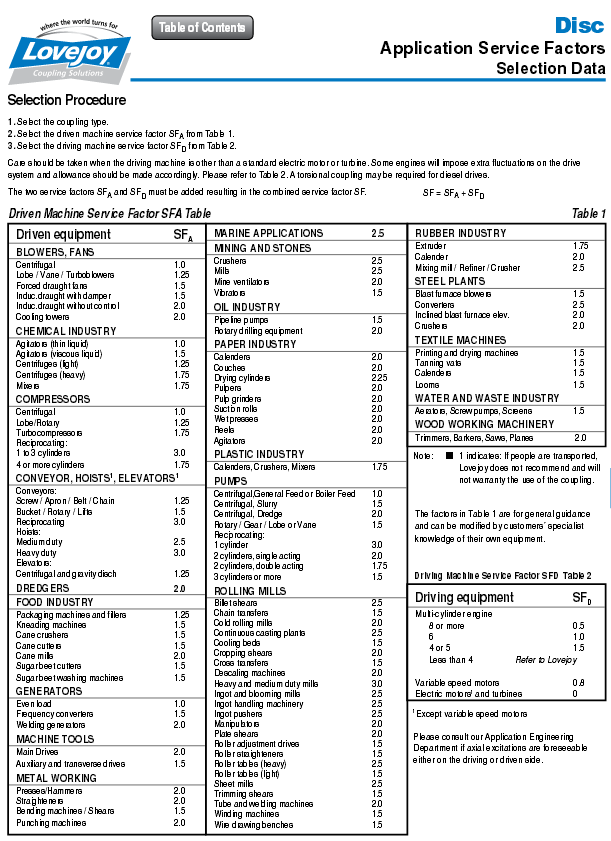

- Select Services factor according to your equipment which has to couple.

Example- For the centrifugal pump to an electric motor, the service factor (SF) is 1.5. which has to couple. And the torque required for running your machine is 10N/M then your coupling should be 1.5 times of the 10 n/m (15n/m) This is not fixed sometimes 1.2 also consider.

In most cases, the purchaser shall choose which type of coupling to be used, whether a flexible type, gear type, quill shaft are other types. Mainly selection of coupling is based on equipment loading of steady-state condition or transient condition of the torque, and angular, axial, or parallel misalignment, and speed.

Shaft Coupling Selection Method

But there are two methods of selecting appropriate coupling for your application.

Selection by kw/100 rpm method

- Select both types of equipment and then choose the required services factor for a given table accordingly.

- Find out required the KW/100 RPM for equipment by using the given formula.

KW/100 rpm = [Motor power (KW)*100*services factor] / Required coupling RPM

- From Rating selection tables, find an appropriate rating equal to or greater than the kw/100 RPM list down coupling size from the left-hand column.

- Check your system maximum RPM.

- Check maximum bore capacity appropriate with your system. If the maximum bore is exceeded, move to a larger size coupling with the adequate bore, but be sure the maximum RPM of coupling is not exceeded.

SELECTION BY TORQUE METHOD

- Select services factor according to application

- Find out the torque (N-M) of your system with the help of the below-mentioned formulas.

Torque (N-M) = [Motor power (KW)*9550*services factor] / Required coupling RPM

- From equipment Rating Tables, find a rating equal to or greater than the calculated torque.

Note coupling size from the column.

- Check max RPM and bore capability. If bore size increases choose coupling size accordingly, but one factor always considers that max RPM should be increased.

Reason for wrong coupling selection

There are five common mistakes that happen during coupling selection for your application.

- Checking the maximum bore size for the application. In some cases, both equipment shaft sizes exceed the maximum bore size of the coupling.

- Fail to identify heat and chemical compatibility due to this coupling reduction.

- Consider installation space required for appropriate selection.

- A common selection for many overrating applications.

- Cost-cutting is the important factor considered.

Term use for coupling selection

Service factors

For your equipment operating condition torque fluctuates cyclically, then service factors play an important factor during selection. But couplings should be selected with the maximum torque that occurs, which will happen in one cycle. So, service’s factor of coupling manufacturers uses to establish a ratio between the maximum and average torque. For your entire system and the ratio is called a service factor.

- How To Install Grid Coupling

- What Are The Gear Coupling And Application

- Important Interview Questions About Shaft Coupling

- What Is Fluid Coupling And Advantage Of Fluid Coupling

- What Is Rigid Coupling And An Overview Of Rigid Coupling