What is ASTM A105?

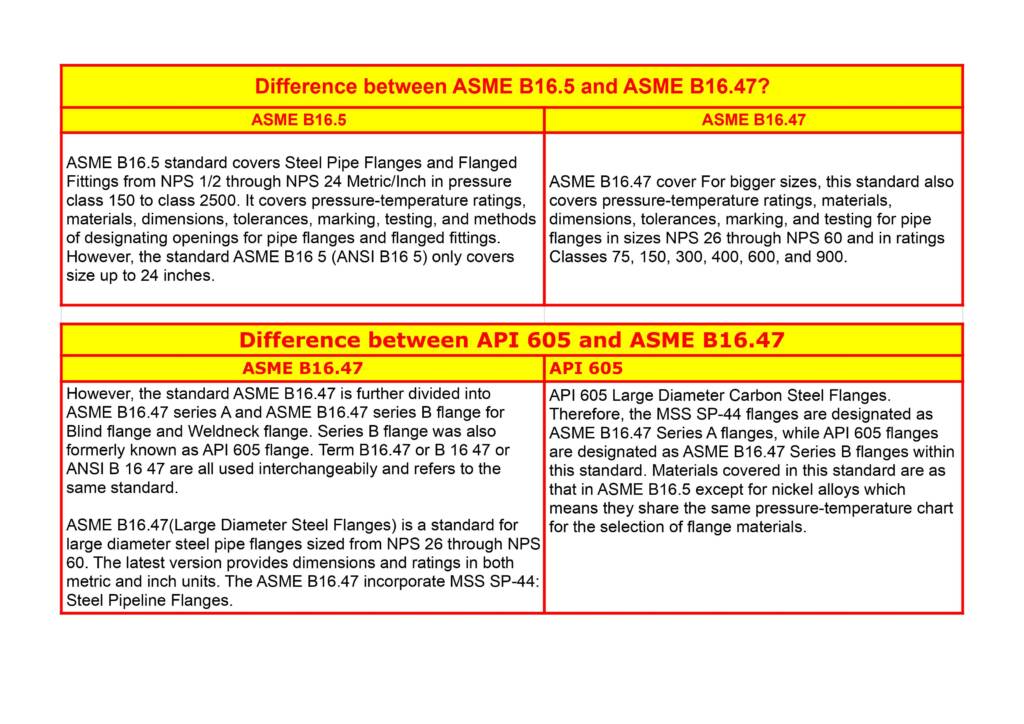

In mechanical ASTM A105 is the same as calling ASME SA 105 under ASME/ANSI B16.5 standard. This is the material grade that is used for carbon steel piping, which covers only seamless forged carbon steel piping components. Generally, it is used for the manufacture of forge piping accessories, like elbow, reducer, many types of flanges for small piping bore size. This carbon steel material grade ASTM A105 is commonly in low and high-temperature service with low- and high-pressure systems as well. This alloy temperature during forge is approx. between 1,700df and 2,200df, followed by quenching and tempering.

What is ASTM A105 and A105N?

ASTM A105 and A105N are both carbon steel specifications used in a variety of industries. ASTM A105 is a standard specification for forged carbon steel piping components, while A105N is a modified version of A105 with the addition of a maximum 0.35% silicon and 0.12% molybdenum. This modification improves the steel’s toughness and resistance to brittle fracture at low temperatures. Both specifications have a maximum carbon content of 0.35%.

Its stands for degree Fahrenheit. The fully killed carbon steel material is used for forging applications. The material form can be put in bar or ingot to meet all types of forging requirements and forgings made to this specification are limited to a maximum weight of 4540 kg. The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such as nominal diameter size and nominal bore size. This specification is expressed in both units inch-pound units and SI.

Heat treatment for ASTM A105

Heat treatment is not mandatory for all applications except for flanges above class 300, flanges of special design where the design pressure or design temperature is not known, and for items over 100 nb or 4 inches and above 300 class rating. The following types of heat treatment are required: annealing, normalizing, normalizing and tempering, normalizing, quench, and tempering shall be the applied methods.

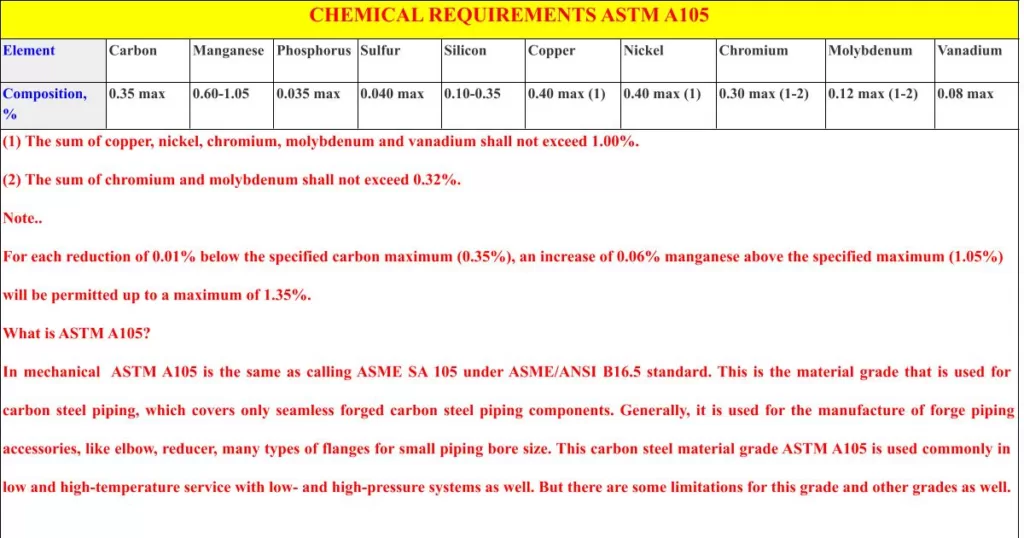

Chemical composition for ASTM A105

All element composition is mentioned in %, c carbon -.35, manganese .60-1.05, phosphorus .035, sulfur .040, silicon .10-35 copper .40, note a nickel.40, note a chromium.30, note a, b molybdenum.12, note a,b vanadium.08, note a. This is the max value considered. Some abbreviation is given below for the above-mentioned short text- note a – this represents the sum of cu, ni, cr, mo, and VA shall not exceed 1.00%. Cu, ni, cr, mo, and VA represent copper, nickel, chromium, molybdenum, and vanadium Note b – this represents the sum of cr & mo shall not exceed .32%. Note c – this represents the sum for each reduction of 0.01% below the specified carbon maximum (.35%), an increase of .06% manganese above the specified maximum (1.05%) will be permitted up to a maximum of 1.65.

Mechanical properties of ASTM A105

The mechanical property for ASTM A105 shall be matched with tensile 70 KSI, min yield, note a -(36 KSI, min) elongation in 2in, the basic minimum for wall 5/16″ and over, strip test – 30%, hardness – 187 HBW max, note a – determined by either the 0.2% offset method or the 0.5% extension-under-load method. Other test methods are available as listed in A105.

Welding process ASTM A105 Grade materials

These components can be welded easily. Welding procedures need to comply with ASME boiler and pressure vessel code section ix. And the procedure of welding also needs to be followed.

What is the difference between A105 and A105N?

Measure difference between ASTM A105Grade & ASTM A105N Grade

ASTM A105 carbon steel forge, flanges, and other fitting are not the same as ASTM A105N, But both have the same raw materials, same carbon steel grades used to construct, but different heat treatment requirements for ASTM A105 & ASTM A105N. The letter N represents normalization heat treatment, and for the A105 materials, the grade haves no heat treatment requirement. ASTM A105N materials grades are the same as the ASTM A105 grade. But ASTM A105N flange has good mechanical properties than A105 materials grade, good in strength, good in performance in low-temperature service. ASTM A105 material grade has the same chemical composition as in ASTM A105N, but the A105N has a better mechanical property and that is used in a critical situation.

Is A105 an alloy?

ASTM A105 is a forge carbon steel materials grade commonly used to cover forged piping components. In this type of carbon steel forging alloy material has a low carbon, manganese and silicon containing steel.

What type of material is ASTM A105?

ASTM A105 is the same as ASME SA 105, that covers seamless forged carbon steel piping components which are used in high- and low-pressure systems at ambient and high-temperature service.

Is A105 killed carbon steel?

Yes this is killed carbon steel material and only killed carbon material is used for forging. So, it can be in the shape of a bar or in the shape of the ingot to meet various forging requirements. And they are allowed maximum machinability and weldability properties.

Heat treatment and impact testing

Both ASTM A105 and A105N require heat treatment after forging or hot working to improve their mechanical properties. The heat treatment involves heating the steel to a specific temperature and then cooling it in a controlled manner. Additionally, both specifications require impact testing to ensure their toughness at low temperatures. However, A105N has stricter requirements for impact testing, with a minimum temperature of -46°C compared to -29°C for A105. This makes A105N a better choice for applications that require high toughness at low temperatures, such as cryogenic storage tanks and pipelines.

Choosing between ASTM A105 and A105N

When choosing between ASTM A105 and A105N, it’s important to consider the specific requirements of your application. A105N is preferred for applications that require high toughness at low temperatures, while A105 is a more versatile specification that can be used in a wider range of applications. Additionally, A105N may be more expensive than A105 due to its higher nickel content. Ultimately, the choice between these two specifications should be based on the desired mechanical properties and the specific needs of your application.