Custom Manufacturing Services: What it is and How It Can Help You to Succeed?

Did you know? The global custom manufacturing services market, valued at $858.8 billion in 2021. By 2031, this market is projected to hit $1,350.2 billion, with a 4.6% CAGR. Contrary to the common perception of automated production lines, custom manufacturing goes beyond mass replication.

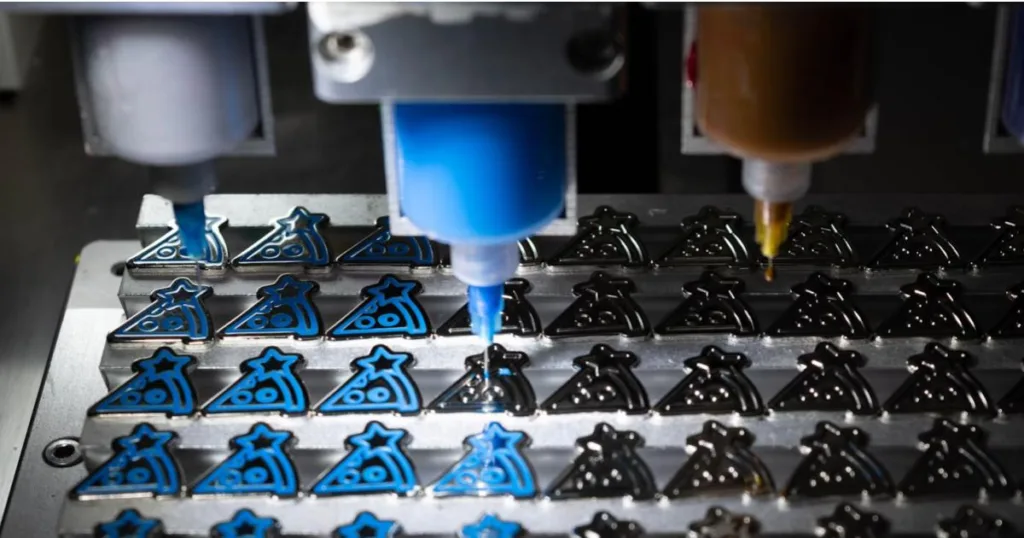

This innovative approach involves designing, engineering, and producing products tailored to individual customer preferences. Common examples of such customized product manufacturing range from build-to-order (BTO) parts to low-volume production and mass customization.

In this article, we’ll delve further into what custom manufacturing service is and its pivotal role in meeting specific business needs.

Source: Unsplash

What are Custom Manufacturing Services?

Custom manufacturing is a process tailored to individual specifications, distinguishing itself from traditional mass production. Unlike the standardized items of mass production, custom manufacturing prioritizes meeting specific customer requirements.

Compared to mass production, custom manufacturing has a different production approach. Notably, it comprises traditional methods focused on quantity, while custom manufacturing centers on addressing the unique needs and preferences of each customer. This shift toward customization offers businesses a remarkable opportunity to differentiate their products in the marketplace.

But that’s not the only difference between mass-manufactured and custom-made products different. The table below runs down on some additional factors that make both manufacturing approaches different.

| Mass Produced Products | Custom Products |

| These products are characterized by uniformity and high-volume production | They offer a high degree of personalization |

| Advantages of such products include cost-efficiency and speed | These products are designed and produced to meet specific customer requirements |

| They often lack uniqueness and personalization | Custom-products result in a unique and tailored product |

| Mass-manufactured products have little room for individual preferences | Such products can lead to higher customer satisfaction and brand loyalty |

| They may not fully meet customer’s needs or expectations | These products manufacturing is more time-consuming and costly |

| They come with challenges in scalability with significant demand increases | They introduce individual design and production processes for each item |

Benefits Of Custom Manufacturing Service

When choosing custom manufacturing services, you can explore endless advantages tailored to your specific manufacturing requirements. These advantages include:

- Functional Tailoring: Custom manufacturing allows for the functional tailoring of designs to precisely match specific needs, ensuring optimal functionality for the end product.

- Cost-Effective Solutions: This type of manufacturing offers cost-effective solutions without compromising on quality, ensuring that businesses can achieve their desired outcomes within budget constraints.

- Reduced Lead Times: Collaboration in custom manufacturing often leads to reduced lead times, enabling the timely delivery of customized products to meet project deadlines.

- Enhanced Product Lifecycle Management: Custom manufacturing provides efficient product lifecycle management, ensuring effective planning, production, and support throughout the entire lifecycle of the product.

- Cutting-Edge Technology: Access to the latest advancements in manufacturing technology is a key benefit of custom manufacturing, allowing businesses to stay competitive and innovative in their processes.

- Flexible Component Acquisition: Custom manufacturing enables the acquisition of necessary components in any quantity, including cost-effective small orders, providing flexibility in production.

- Expert Collaboration: Collaborating with industry-leading manufacturing experts in custom manufacturing elevates product quality through specialized knowledge and experience.

- Scalable Business Growth: Custom manufacturing allows for easily scalable business growth, adapting production capabilities to changing needs and market demands.

- Precision in Product Creation: Custom manufacturing enables the creation of exact products needed, avoiding generic, mass-produced alternatives and ensuring a tailored solution.

- Quality Control Excellence: Custom manufacturing emphasizes improved quality control measures, ensuring that customized products meet high standards and specifications.

Final Thoughts

Custom manufacturing service, while requiring a higher upfront investment, offers significant benefits in product quality, customer satisfaction, and competitive advantage.

At the same time, custom manufacturing services also present challenges such as increased costs, longer production times. Not to mention the need for skilled labor and advanced technology being another common challenge of such manufacturing service.

Despite both advantages and drawbacks, tailoring products to meet specific customer needs is a smart way to introduce innovation and competitiveness. As a result, this manufacturing has now become a crucial aspect of the dynamic manufacturing market.