What Are ASME/ANSI B16.9 Fittings?

ASME/ANSI B16.9 fittings standard specification are cover only the butt weld fittings. That are followed to connect pipes with other fittings components in industrial piping systems. These fittings are made from a wide variety of materials, like carbon steel, stainless steel, alloy steels, nickel alloys, and titanium for high-temperature applications. The specifications set out by ASME/ANSI B16.9 outline the dimensional and pressure requirements for these fittings.

The ASME/ANSI B16.9 fitting specification outlines standards for butt weld fittings, which are used to connect piping systems in industrial applications. With an understanding of this standard, you can ensure accuracy and safety in your piping system design.

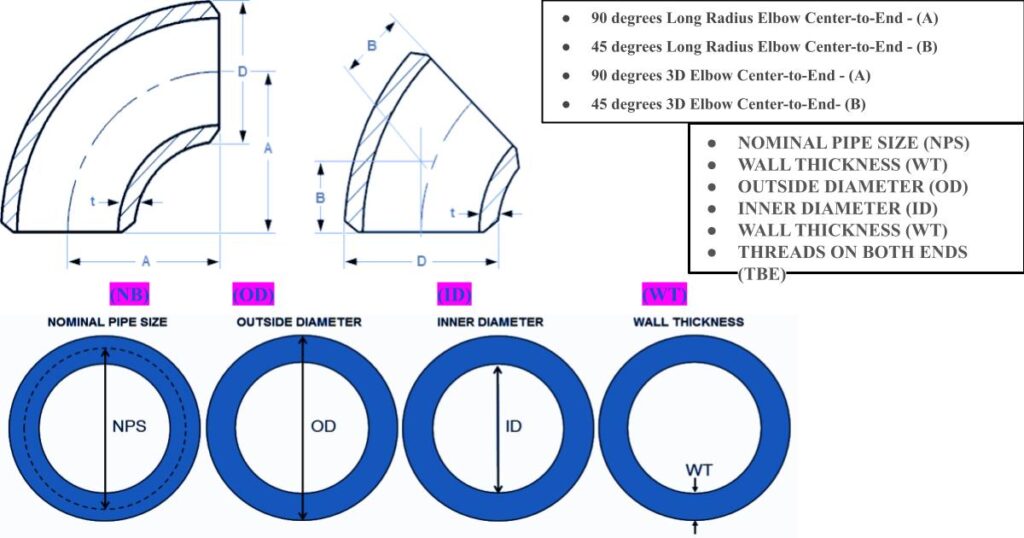

Dimensions for 45 and 90 Degrees Elbows in Long Radius and Short Radius

When using ASME/ANSI B16.9 fittings, it is important to be aware of the dimensional requirements for both 45 degree and 90 degree elbows in a long radius or short radius. For 45° elbows in long radius form, the outside diameter of the fitting must be between 1.25 and 24 inches, with a maximum center-to-end distance of 2 times the nominal size of the pipe. For 90° elbows in short radius form, this outside diameter should also be between 1.25 and 24 inches, but with a center-to-end distance that is equal to the nominal size of the pipe.

Dimensions of Straight Tees, Reducing Tees, Caps, Olets and Outlets

That standard specification also covers straight tees and other fittings that are available in diameters ranging from 1.25 to 24 inches, with the center-to-end distance of its run pipe equal to its nominal size. Reducing tees must have a run pipe with an outside diameter no greater than that of its branch pipe, also with a maximum center-to-end distance equal to the nominal size. Caps fittings have an outside diameter that is between 1.25 and 24 inches, while olets and outlets must have a minimum outside diameter of 3/4 inch and a maximum overall length of 6 times the fitting’s outside diameter.

Manufacturers Standardization Society (MSS) Standard

It is important to reference MSS SP-44 when buying standard size fittings, as it outlines the various dimensions used to fit pipes. The inner outside diameter (ID) and outer outside diameter (OD) of a fitting’s ends must match the nominal pipe size’s ID and OD respectively. For example, the most common ID measurement for a 1/2 inch fitting is 0.531 inches with an OD of 0.8438 inches. Additionally, socket weld fittings must conform to the requirements of ANSI B16.11 which specifies the pressure classes and overall length of each product type.

Impact of Errata on Document Quality & Compliance

Errata are changes to ASME/ANSI B16.9 documents that can impact product quality and compliance standards. Errata should be taken into consideration when it comes to ordering, purchasing, or installing fittings. Types of errors include corrections, additions and deletions. Be sure to check the issuing date of the document and any publication errors that have been issued since the document was released in order to ensure you have accurate information.

Dimensions chart for 45 and 90 Degrees Elbows

|

|

| NPS | NB (MM) | O.D (D) | 90° LR (A) | 45° LR (B) | 90° 3D (A) | 45° 3D (B) |

| 1/2″ | 15mm | 21.3 | 38 | 16 | ||

| 3/4″ | 20mm | 26.7 | 38 | 19 | 57 | 24 |

| 1″ | 25mm | 33.4 | 38 | 22 | 76 | 31 |

| 1 1/4″ | 32mm | 42.2 | 48 | 25 | 95 | 39 |

| 1 1/2″ | 40mm | 48.3 | 57 | 29 | 114 | 47 |

| 1 2″ | 50mm | 60.3 | 76 | 35 | 152 | 63 |

| 2 1/2″ | 65mm | 73 | 95 | 44 | 190 | 79 |

| 3″ | 80mm | 88.9 | 114 | 51 | 229 | 95 |

| 3.1/2″ | 87.5mm | 101.6 | 133 | 57 | 267 | 111 |

| 4″ | 100mm | 114.3 | 152 | 64 | 305 | 127 |

| 5″ | 125mm | 141.3 | 190 | 79 | 381 | 157 |

| 6″ | 150mm | 168.3 | 229 | 95 | 457 | 189 |

| 8″ | 200mm | 219.1 | 305 | 127 | 610 | 252 |

| 10″ | 250mm | 273 | 381 | 159 | 762 | 316 |

| 12″ | 300mm | 323.8 | 457 | 190 | 914 | 378 |

| 14″ | 350mm | 355.6 | 533 | 222 | 1067 | 441 |

| 16″ | 400mm | 406.4 | 610 | 254 | 1219 | 505 |

| 18″ | 450mm | 457 | 686 | 286 | 1372 | 568 |

| 20″ | 500mm | 508 | 762 | 318 | 1524 | 632 |

| 22″ | 550mm | 559 | 838 | 343 | 1676 | 694 |

| 24″ | 600mm | 610 | 914 | 381 | 1829 | 757 |

| 26″ | 650mm | 660 | 991 | 406 | 1981 | 821 |

| 28″ | 700mm | 711 | 1067 | 438 | 2134 | 883 |

| 30″ | 750mm | 762 | 1143 | 470 | 2286 | 946 |

| 32″ | 800mm | 813 | 1219 | 502 | 2438 | 1010 |

| 34″ | 850mm | 864 | 1295 | 533 | 2591 | 1073 |

| 36″ | 900mm | 914 | 1372 | 565 | 2743 | 1135 |

| 38″ | 950mm | 965 | 1448 | 600 | 2896 | 1200 |

| 40″ | 1000mm | 1016 | 1524 | 632 | 3048 | 1264 |

| 42″ | 1050mm | 1067 | 1600 | 660 | 3200 | 1326 |

| 44″ | 1100mm | 1118 | 1676 | 695 | 3353 | 1389 |

| 46″ | 1150mm | 1168 | 1753 | 727 | 3505 | 1453 |

| 48″ | 1200mm | 1219 | 1829 | 759 | 3658 | 1516 |