MS Bolts Weight Charts for Selection

Our comprehensive MS bolt weight charts for selection are here to make your selection easier. Whether you are a professional or enthusiast, having the right information at your fingertips is vital for a successful project. With this essential resource, you can choose the right bolts for your specific applications, ensuring optimal performance and safety. Our MS bolt weight charts are meticulously organized and user-friendly, making it easy for you to find the exact information you need, precisely when you need it. Save time and effort by having all the necessary information right at your fingertips. Don’t waste any more time searching for accurate bolt weight information. Trust our MS bolt weight charts for selection and make your projects go smoothly from start to finish.

Understanding Bolt Weight Charts:

Importance of Selecting the Right Bolt Weight:

- Safety: Choosing the appropriate bolt weight is crucial for the safety and structural integrity of the application. Using bolts that are too lightweight may compromise the stability of the structure.

- Load Distribution: Bolt weight contributes to load distribution. Properly sized bolts help distribute loads evenly, preventing stress concentrations that can lead to failure.

- Material Compatibility: The weight of the bolt should match the material and design specifications of the joint to ensure optimal performance and longevity.

Factors to Consider When Choosing Bolt Weight:

Material Strength: Consider the material strength of the bolts in relation to the materials being joined. Bolts with higher strength may be required for heavy-duty applications.

Environmental Conditions: Environmental factors such as corrosion, temperature, and exposure to chemicals can impact the choice of bolt weight. Corrosion-resistant bolts may be necessary in corrosive environments.

Load Requirements: The magnitude and type of load the bolts will bear influence the selection. High-stress applications may require heavier bolts to handle the load.

M.S. HEX FULL THREAD BOLTS WITH NUTS WEIGHT

M.S. HEX BOLTS WEIGHT CHARTS IN MM

| APPROX WEIGHT IN KGS FOR 100 NOS. BOLTS WITH NUTS | ||||||||||||

|

LENGTH

|

D I A M E T E R | |||||||||||

| M 2 | M 3 | M 4 | M 5 | M 6 | M 7 | M 8 | M 10 | M 12 | M 14 | M 16 | M 18 | |

| 12 mm | 0.05 | 0.12 | 0.25 | 0.40 | 0.67 | 0.99 | 1.46 | 2.94 | 4.34 | |||

| 16 mm | 0.05 | 0.13 | 0.28 | 0.45 | 0.74 | 1.08 | 1.59 | 3.14 | 4.62 | |||

| 20 mm | 0.15 | 0.31 | 0.50 | 0.81 | 1.19 | 1.71 | 3.34 | 4.90 | ||||

| 25 mm | 0.17 | 0.35 | 0.56 | 0.90 | 1.30 | 1.87 | 3.60 | 5.26 | 7.72 | 10.12 | 14.12 | |

| 30 mm | 0.39 | 0.62 | 0.98 | 1.44 | 2.03 | 3.84 | 5.62 | 8.21 | 10.80 | 15.02 | ||

| 35 mm | 0.43 | 0.68 | 1.07 | 1.56 | 2.19 | 4.10 | 5.98 | 8.71 | 11.47 | 15.82 | ||

| 40 mm | 0.46 | 0.75 | 1.16 | 1.69 | 2.35 | 4.34 | 6.35 | 9.21 | 12.14 | 16.61 | ||

| 45 mm | 0.50 | 0.81 | 1.24 | 1.81 | 2.51 | 4.60 | 6.70 | 9.73 | 12.85 | 17.42 | ||

| 50 mm | 0.54 | 0.87 | 1.33 | 1.94 | 2.66 | 4.85 | 7.05 | 10.23 | 13.44 | 18.25 | ||

| 55 mm | 0.58 | 0.93 | 1.42 | 2.06 | 2.83 | 5.10 | 7.42 | 10.71 | 14.12 | 19.16 | ||

| 60 mm | 0.62 | 0.99 | 1.50 | 2.18 | 2.98 | 5.36 | 7.78 | 11.21 | 14.84 | 19.92 | ||

| 65 mm | 0.66 | 1.06 | 1.59 | 2.31 | 3.15 | 5.61 | 8.14 | 11.71 | 15.43 | 20.75 | ||

| 70 mm | 0.70 | 1.12 | 1.67 | 2.43 | 3.31 | 5.86 | 8.50 | 12.23 | 16.13 | 21.55 | ||

| 75 mm | 1.18 | 1.76 | 2.56 | 3.47 | 6.11 | 8.87 | 12.63 | 16.89 | 22.42 | |||

| 80 mm | 1.24 | 1.85 | 2.68 | 3.63 | 6.36 | 9.23 | 13.16 | 17.54 | 23.26 | |||

| 85 mm | 1.93 | 2.81 | 3.79 | 6.61 | 9.58 | 13.66 | 18.18 | 24.04 | ||||

| 90 mm | 2.02 | 2.93 | 3.95 | 6.87 | 9.94 | 14.16 | 18.87 | 24.88 | ||||

| 100 mm | 2.19 | 3.18 | 4.26 | 7.36 | 10.66 | 15.15 | 20.16 | 26.46 | ||||

| 110 mm | 2.36 | 4.58 | 7.89 | 11.39 | 16.18 | 21.65 | 28.25 | |||||

| 120 mm | 2.73 | 4.95 | 8.38 | 12.14 | 17.18 | 22.94 | 29.94 | |||||

| 130 mm | 2.87 | 5.30 | 8.88 | 12.82 | 18.18 | 24.16 | 31.65 | |||||

| 140 mm | 3.01 | 5.59 | 9.38 | 13.51 | 19.23 | 25.64 | 33.33 | |||||

| 150 mm | 3.18 | 5.87 | 9.88 | 14.25 | 20.24 | 27.03 | 34.72 | |||||

| 160 mm | 10.04 | 14.62 | 28.57 | 36.50 | ||||||||

| 170 mm | 10.40 | 15.53 | 29.94 | 38.17 | ||||||||

| 180 mm | 11.26 | 16.34 | 30.86 | 39.68 | ||||||||

| 190 mm | 17.01 | 32.26 | 41.67 | |||||||||

| 200 mm | 12.17 | 17.79 | 33.11 | 43.10 | ||||||||

| 225 mm | 19.31 | 36.77 | ||||||||||

| 250 mm | 14.75 | 21.65 | 40.00 | |||||||||

| 300 mm | 24.63 | 47.17 | ||||||||||

|

LENGTH

|

D I A M E T E R WEIGHT BOLTS WITH NUTS | |||||||||||

| M 20 | M 22 | M 24 | M 27 | M 30 | M 33 | M 36 | M 39 | M 42 | M 45 | M 48 | M 52 | |

| 25 mm | 18.73 | |||||||||||

| 30 mm | 19.76 | |||||||||||

| 35 mm | 20.83 | 25.38 | ||||||||||

| 40 mm | 21.83 | 26.60 | 34.97 | |||||||||

| 45 mm | 22.83 | 27.93 | 36.50 | |||||||||

| 50 mm | 24.04 | 29.24 | 38.17 | 53.76 | 72.46 | 92.59 | ||||||

| 55 mm | 25.00 | 30.68 | 39.37 | 56.18 | 74.63 | 96.15 | ||||||

| 60 mm | 26.04 | 31.85 | 40.98 | 57.47 | 76.92 | 98.04 | 125.00 | 161.29 | 185.19 | 277.78 | ||

| 65 mm | 27.03 | 33.11 | 42.74 | 60.24 | 79.37 | 102.04 | 131.58 | 161.29 | 192.31 | 238.10 | 357.14 | |

| 70 mm | 28.09 | 34.48 | 44.25 | 61.73 | 81.97 | 104.17 | 135.14 | 166.67 | 294.12 | |||

| 75 mm | 29.07 | 35.71 | 45.87 | 64.10 | 84.75 | 108.70 | 138.89 | 178.57 | 200.00 | 250.00 | ||

| 80 mm | 30.30 | 37.04 | 47.17 | 65.79 | 87.72 | 111.11 | 142.86 | 178.57 | ||||

| 85 mm | 31.25 | 38.17 | 48.54 | 67.57 | 89.29 | 113.64 | 147.06 | 185.19 | 208.33 | 263.16 | 312.50 | 384.62 |

| 90 mm | 32.26 | 39.68 | 50.00 | 69.44 | 92.59 | 116.28 | 151.52 | 192.31 | 217.39 | |||

| 100 mm | 34.48 | 42.37 | 53.19 | 73.53 | 96.15 | 121.95 | 156.25 | 200.00 | 227.27 | 277.78 | 333.33 | 416.67 |

| 110 mm | 36.50 | 45.05 | 56.18 | 78.13 | 102.04 | 128.21 | 166.67 | 208.33 | 238.10 | 294.12 | ||

| 120 mm | 38.46 | 47.62 | 59.52 | 81.97 | 106.38 | 135.14 | 172.41 | 208.33 | 250.00 | 357.14 | ||

| 130 mm | 40.98 | 50.00 | 62.50 | 86.21 | 111.11 | 142.86 | 178.57 | 227.27 | 312.50 | 384.62 | 454.55 | |

| 140 mm | 42.74 | 52.63 | 65.79 | 89.29 | 116.28 | 147.06 | 185.19 | 238.10 | 263.16 | 333.33 | ||

| 150 mm | 45.05 | 55.56 | 68.49 | 94.34 | 121.95 | 151.52 | 192.31 | 250.00 | 277.78 | |||

| 160 mm | 47.17 | 57.47 | 71.43 | 98.04 | 128.21 | 161.29 | 200.00 | 250.00 | 416.67 | 500.00 | ||

| 170 mm | 49.02 | 60.24 | 74.63 | 102.04 | 131.58 | 166.67 | 208.33 | 263.16 | 294.12 | 357.14 | ||

| 180 mm | 51.02 | 62.50 | 79.37 | 106.38 | 135.14 | 178.57 | 217.39 | 263.16 | 555.56 | |||

| 190 mm | 53.19 | 65.79 | 80.65 | 111.11 | 142.86 | 178.57 | 227.27 | 277.78 | 312.50 | |||

| 200 mm | 54.95 | 68.49 | 84.75 | 113.64 | 147.06 | 185.19 | 227.27 | 294.12 | 333.33 | 384.62 | 454.55 | 625.00 |

| 225 mm | 60.24 | 92.59 | 156.25 | |||||||||

| 250 mm | 65.79 | 100.00 | 172.41 | |||||||||

| 300 mm | 78.13 | 113.64 | 192.31 | |||||||||

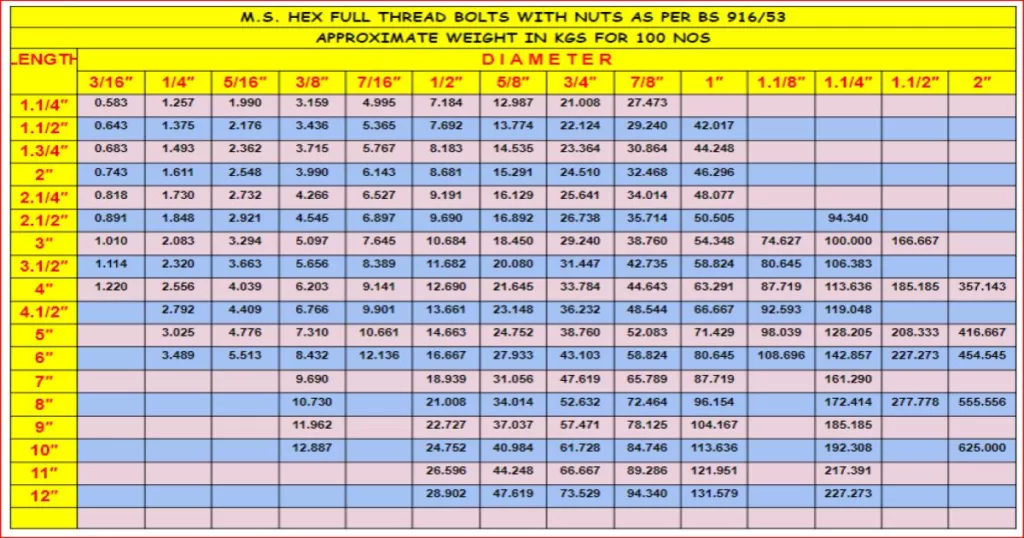

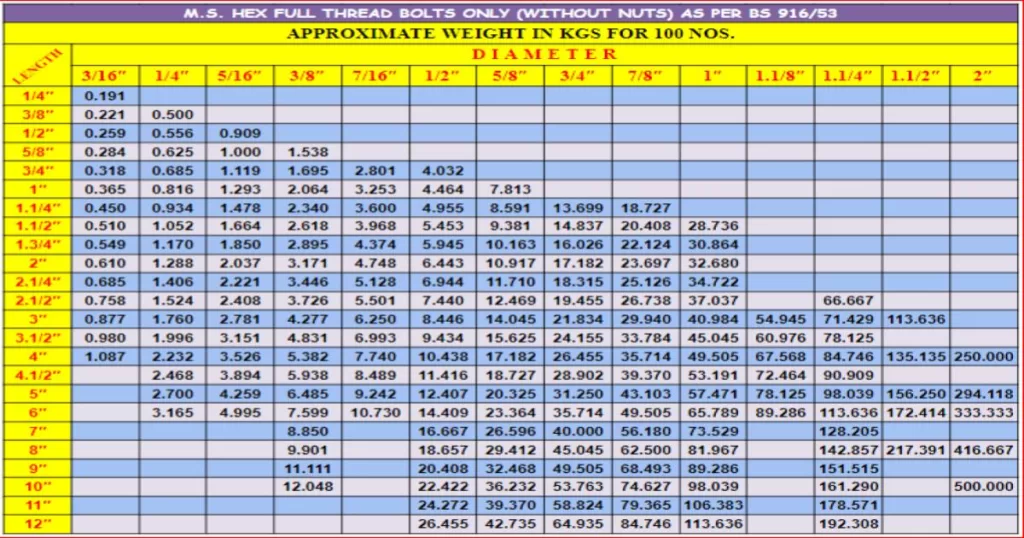

M.S. HEX BOLTS WEIGHT CHARTS IN INCH

M.S. HEX BOLTS WEIGHT CHARTS IN INCH

M.S. HEX BOLTS ONLY (WITHOUT NUTS) | FULL THREAD

HEX BOLTS ONLY (WITHOUT NUTS) IN MM

| APPROXIMATE WEIGHT IN KGS FOR 100 NOS. | |||||||||||||

|

LENGTH

|

D I A M E T E R | ||||||||||||

| M 1.6 | M 2 | M 2.5 | M 2.6 | M 3 | M 3.5 | M 4 | M 5 | M 6 | M 7 | M 8 | M 10 | M 12 | |

| 3 mm | 0.011 | 0.020 | 0.037 | 0.038 | |||||||||

| 4 mm | 0.012 | 0.021 | 0.040 | 0.041 | 0.048 | ||||||||

| 5 mm | 0.013 | 0.023 | 0.043 | 0.044 | 0.053 | 0.084 | 0.126 | ||||||

| 6 mm | 0.014 | 0.025 | 0.046 | 0.047 | 0.057 | 0.090 | 0.133 | 0.218 | 0.340 | 0.543 | |||

| 8 mm | 0.016 | 0.029 | 0.052 | 0.054 | 0.066 | 0.102 | 0.149 | 0.238 | 0.374 | 0.593 | 0.855 | ||

| 10 mm | 0.018 | 0.033 | 0.058 | 0.060 | 0.075 | 0.114 | 0.164 | 0.263 | 0.408 | 0.643 | 0.910 | ||

| 12 mm | 0.020 | 0.036 | 0.064 | 0.067 | 0.084 | 0.126 | 0.180 | 0.287 | 0.442 | 0.692 | 0.980 | 1.920 | 2.741 |

| 16 mm | 0.042 | 0.076 | 0.081 | 0.100 | 0.150 | 0.210 | 0.337 | 0.511 | 0.786 | 1.110 | 2.120 | 3.021 | |

| 20 mm | 0.088 | 0.093 | 0.118 | 0.173 | 0.241 | 0.387 | 0.580 | 0.891 | 1.230 | 2.320 | 3.300 | ||

| 25 mm | 0.102 | 0.109 | 0.140 | 0.203 | 0.280 | 0.449 | 0.665 | 1.010 | 1.390 | 2.571 | 3.660 | ||

| 30 mm | 0.319 | 0.511 | 0.751 | 1.140 | 1.550 | 2.820 | 4.023 | ||||||

| 35 mm | 0.357 | 0.573 | 0.837 | 1.260 | 1.711 | 3.071 | 4.382 | ||||||

| 40 mm | 0.396 | 0.635 | 0.923 | 1.390 | 1.871 | 3.320 | 4.744 | ||||||

| 45 mm | 0.434 | 0.699 | 1.010 | 1.510 | 2.030 | 3.571 | 5.102 | ||||||

| 50 mm | 0.473 | 0.759 | 1.100 | 1.640 | 2.181 | 3.823 | 5.453 | ||||||

| 55 mm | 0.512 | 0.821 | 1.190 | 1.761 | 2.341 | 4.072 | 5.814 | ||||||

| 60 mm | 0.550 | 0.883 | 1.270 | 1.880 | 2.500 | 4.333 | 6.173 | ||||||

| 65 mm | 0.589 | 0.945 | 1.360 | 2.010 | 2.661 | 4.583 | 6.536 | ||||||

| 70 mm | 0.628 | 1.010 | 1.440 | 2.130 | 2.820 | 4.831 | 6.897 | ||||||

| 75 mm | 1.070 | 1.530 | 2.260 | 2.982 | 5.081 | 7.257 | |||||||

| 80 mm | 1.130 | 1.620 | 2.381 | 3.141 | 5.330 | 7.610 | |||||||

| 85 mm | 1.700 | 2.510 | 3.300 | 5.580 | 7.974 | ||||||||

| 90 mm | 1.790 | 2.630 | 3.460 | 5.834 | 8.333 | ||||||||

| 100 mm | 1.961 | 2.880 | 3.771 | 6.337 | 9.058 | ||||||||

| 110 mm | 2.128 | 4.092 | 6.849 | 9.785 | |||||||||

| 120 mm | 2.500 | 4.464 | 7.342 | 10.504 | |||||||||

| 130 mm | 2.632 | 4.808 | 7.849 | 11.211 | |||||||||

| 140 mm | 2.778 | 5.102 | 8.347 | 11.905 | |||||||||

| 150 mm | 2.941 | 5.376 | 8.850 | 12.626 | |||||||||

| 160 mm | 9.009 | 12.987 | |||||||||||

| 170 mm | 9.346 | 13.889 | |||||||||||

| 180 mm | 10.204 | 14.706 | |||||||||||

| 190 mm | 15.385 | ||||||||||||

| 200 mm | 11.111 | 16.129 | |||||||||||

| 220 mm | 17.668 | ||||||||||||

| 250 mm | 13.699 | 20.000 | |||||||||||

| 300 mm | 22.936 | ||||||||||||

| APPROXIMATE WEIGHT IN KGS FOR 100 NOS. | |||||||||||||||

|

LENGTH

|

D I A M E T E R | ||||||||||||||

| M 14 | M 16 | M 18 | M 20 | M 22 | M 24 | M 27 | M 30 | M 33 | M 36 | M 39 | M 42 | M 45 | M 48 | M 52 | |

| 25 mm | 5.3 | 7.0 | 9.7 | 12.6 | |||||||||||

| 30 mm | 5.8 | 7.7 | 10.5 | 13.6 | |||||||||||

| 35 mm | 6.3 | 8.4 | 11.3 | 14.7 | 18.1 | ||||||||||

| 40 mm | 6.8 | 9.0 | 12.1 | 15.7 | 19.3 | 24.5 | |||||||||

| 45 mm | 7.3 | 9.7 | 12.9 | 16.7 | 20.7 | 25.9 | |||||||||

| 50 mm | 7.8 | 10.3 | 13.7 | 17.9 | 21.9 | 27.5 | 37.9 | 50.0 | 63.3 | ||||||

| 55 mm | 8.3 | 11.0 | 14.6 | 18.9 | 23.3 | 28.9 | 40.0 | 52.1 | 66.7 | ||||||

| 60 mm | 8.8 | 11.7 | 15.4 | 19.9 | 24.5 | 30.5 | 41.7 | 54.3 | 69.4 | 86.2 | 108.7 | 128.2 | 156.3 | 185.2 | 227.3 |

| 65 mm | 9.3 | 12.3 | 16.2 | 20.9 | 25.8 | 32.1 | 43.9 | 56.8 | 72.5 | 90.9 | 111.1 | 131.6 | 161.3 | 192.3 | 238.1 |

| 70 mm | 9.8 | 13.0 | 17.0 | 21.9 | 27.0 | 33.6 | 45.5 | 59.5 | 74.6 | 94.3 | 116.3 | 138.9 | 166.7 | 200.0 | 250.0 |

| 75 mm | 10.2 | 13.7 | 17.9 | 22.9 | 28.2 | 35.0 | 47.6 | 61.7 | 78.1 | 98.0 | 122.0 | 142.9 | 172.4 | 208.3 | 250.0 |

| 80 mm | 10.7 | 14.4 | 18.7 | 24.0 | 29.6 | 36.5 | 49.5 | 64.1 | 80.6 | 100.0 | 125.0 | 147.1 | 178.6 | 208.3 | 263.2 |

| 85 mm | 11.2 | 15.0 | 19.5 | 25.0 | 30.9 | 37.9 | 51.5 | 66.7 | 84.7 | 104.2 | 128.2 | 151.5 | 185.2 | 217.4 | 263.2 |

| 90 mm | 11.7 | 15.7 | 20.3 | 26.0 | 32.3 | 39.4 | 53.2 | 69.4 | 87.7 | 108.7 | 135.1 | 156.3 | 192.3 | 227.3 | 277.8 |

| 100 mm | 12.7 | 17.0 | 21.9 | 28.2 | 34.7 | 42.4 | 57.5 | 73.5 | 92.6 | 116.3 | 142.9 | 166.7 | 200.0 | 238.1 | 294.1 |

| 110 mm | 13.7 | 18.5 | 23.7 | 30.3 | 37.3 | 45.5 | 61.0 | 78.1 | 98.0 | 122.0 | 151.5 | 178.6 | 217.4 | 250.0 | 312.5 |

| 120 mm | 14.7 | 19.8 | 25.3 | 32.3 | 40.0 | 48.5 | 64.9 | 83.3 | 104.2 | 128.2 | 156.3 | 185.2 | 227.3 | 263.2 | 312.5 |

| 130 mm | 15.7 | 21.0 | 27.0 | 34.5 | 42.4 | 51.5 | 69.4 | 87.7 | 111.1 | 135.1 | 166.7 | 200.0 | 238.1 | 277.8 | 333.3 |

| 140 mm | 16.7 | 22.4 | 28.6 | 36.5 | 45.0 | 54.3 | 72.5 | 92.6 | 116.3 | 142.9 | 178.6 | 208.3 | 250.0 | 294.1 | 357.1 |

| 150 mm | 17.7 | 23.8 | 30.1 | 38.5 | 47.6 | 57.5 | 76.9 | 98.0 | 122.0 | 151.5 | 185.2 | 217.4 | 263.2 | 294.1 | 357.1 |

| 160 mm | 25.3 | 31.8 | 40.7 | 50.0 | 60.2 | 80.6 | 102.0 | 128.2 | 156.3 | 192.3 | 227.3 | 263.2 | 312.5 | 384.6 | |

| 170 mm | 26.7 | 33.3 | 42.7 | 52.6 | 63.3 | 84.7 | 106.4 | 135.1 | 166.7 | 200.0 | 238.1 | 277.8 | 333.3 | 416.7 | |

| 180 mm | 27.6 | 35.0 | 44.6 | 54.9 | 67.6 | 87.7 | 111.1 | 142.9 | 172.4 | 208.3 | 250.0 | 294.1 | 333.3 | 416.7 | |

| 190 mm | 29.1 | 36.8 | 46.7 | 57.5 | 69.4 | 92.6 | 116.3 | 147.1 | 178.6 | 217.4 | 250.0 | 312.5 | 357.1 | 416.7 | |

| 200 mm | 29.8 | 38.2 | 48.5 | 60.2 | 72.5 | 96.2 | 122.0 | 151.5 | 185.2 | 227.3 | 263.2 | 312.5 | 357.1 | 454.5 | |

| 220 mm | 33.3 | 53.8 | 80.6 | 131.6 | |||||||||||

| 250 mm | 36.5 | 58.8 | 87.7 | 142.9 | |||||||||||

| 300 mm | 43.9 | 70.4 | 102.0 | 166.7 | |||||||||||

HEX BOLTS ONLY (WITHOUT NUTS) IN INCHES

Common MS Bolt Weight Charts:Mild Steel (MS) bolt weight charts provide information on the weight of bolts based on their dimensions (diameter, length, etc.). These charts often categorize bolts into different grades or classes, each designed for specific applications and load capacities.

How to Read and Interpret Bolt Weight Charts:

Diameter and Length: Bolt weight charts typically list bolts by diameter and length. Select the appropriate size based on the requirements of your application.

Grade/Class: Different grades or classes of bolts have varying strength characteristics. Ensure the selected grade meets the required specifications for your project.

Weight per Unit: The weight per unit (e.g., weight per meter or weight per piece) is provided in the chart. Use this information to calculate the total weight based on the quantity required.

Additional Considerations:

Torque Requirements: Bolts need to be tightened to a specific torque. Ensure the selected bolt weight allows for proper torquing without compromising the integrity of the joint.

Industry Standards: Consider relevant industry standards (e.g., ASTM, ISO) for bolt specifications. Adhering to these standards ensures the bolts meet quality and safety requirements.

Examples of Different Bolt Weight Selections:

Light-Duty Application | Selection: A low-strength, lightweight bolt may be suitable for assembling furniture or other non-load-bearing structures where the primary concern is ease of installation.

Medium-Duty Structural Connection | Selection: For moderate load-bearing applications, such as connecting steel beams in a residential structure, a mid-range bolt with a balanced weight-to-strength ratio might be chosen.

Heavy-Duty Industrial Machinery | Selection: In applications where high loads are anticipated, such as securing heavy machinery components, a heavy-duty bolt with a higher weight and greater strength would be selected for durability and safety.

Tips for Using Bolt Weight Charts Effectively:

Define Application Requirements: Clearly understand the load, environmental conditions, and other factors affecting the joint. This will help narrow down the range of suitable bolt weights.

Refer to Standards: Consult relevant industry standards to ensure compliance. Standards provide guidelines on the appropriate bolt grades and weights for specific applications.

Consider Corrosion Resistance: In corrosive environments, prioritize bolts with corrosion-resistant coatings. The bolt weight chart should specify the type of coating and its impact on weight.

Calculate Total Weight: Use the weight per unit information in the chart to calculate the total weight of bolts required for a particular project. Consider both individual bolt weight and the quantity needed.

Tools and Resources for Finding Bolt Weight Charts:

Manufacturer Specifications: Manufacturers often provide detailed specifications and charts for their bolt products. Check with the manufacturer for the most accurate and up-to-date information.

Engineering Handbooks: Engineering handbooks and manuals, such as those from organizations like ASTM or ASME, often include bolt weight charts along with guidelines for their selection.

Online Databases: Explore online databases and resources that compile bolt specifications and charts. These can be valuable references for various bolt types and applications.

Engineering Software: Some engineering software tools include databases or modules that assist in selecting appropriate bolt sizes based on application requirements. These tools can streamline the selection process.

Conclusion and Final Thoughts:

Selecting the right bolt weight is a critical aspect of ensuring the safety and performance of any construction or manufacturing project. Bolt weight charts offer valuable information, and by considering factors such as load requirements, environmental conditions, and adherence to standards, one can make informed choices. Using these charts effectively involves careful consideration of application needs, proper calculations, and consulting reliable tools and resources. Always prioritize safety and compliance with industry standards when working with bolted joints.