Introduction to Piping Support

Piping systems form the circulatory system of industrial plants, power generation facilities, commercial buildings, and various other infrastructures. They transport fluids, gases, and other substances critical to the operation of these structures. To ensure the integrity, safety, and longevity of piping systems, adequate support is indispensable. This chapter delves into the fundamental aspects of piping support, highlighting its importance, its pivotal role within piping systems, and outlining the key objectives of this article.

The Importance of Piping Support

Imagine a complex network of pipes, each carrying different substances under varying pressures and temperatures. Without proper support, this intricate web of conduits would be susceptible to a range of issues that could jeopardize safety, functionality, and the structural integrity of the entire system. The importance of piping support cannot be overstated, and here’s why:

- Alignment and Leveling

- Maintenance Access

- Stress Management

- Vibration Damping

- Safety Assurance

Role in Piping Systems

Piping support plays a multifaceted role within piping systems. Its functions encompass not only the physical support of pipes but also several critical operational aspects:

- Load Distribution: Piping support evenly distributes the weight of pipes and their contents, preventing localized stress points that could lead to failure.

- Thermal Expansion Management: Piping materials expand and contract with temperature variations. Support systems accommodate these movements to prevent buckling, bending, or distortion.

- Vibration Control: Vibrations generated during fluid flow or equipment operation can weaken pipes and connections. Support structures minimize these vibrations, enhancing system longevity.

- Alignment and Leveling: Accurate alignment and leveling are essential for proper flow rates, pressure readings, and system efficiency. Piping support ensures that pipes are correctly positioned.

- Structural Integrity: Piping support contributes to the overall structural integrity of the facility. It prevents sagging, excessive movement, and misalignment, preserving the integrity of the entire system.

Types of Piping Support

Types of Piping Support

Piping support is a critical component of any piping system, and various types of support mechanisms are employed to ensure the stability, safety, and functionality of pipelines. In this chapter, we will explore some of the most commonly used types of piping support, including pipe hangers and their subtypes.

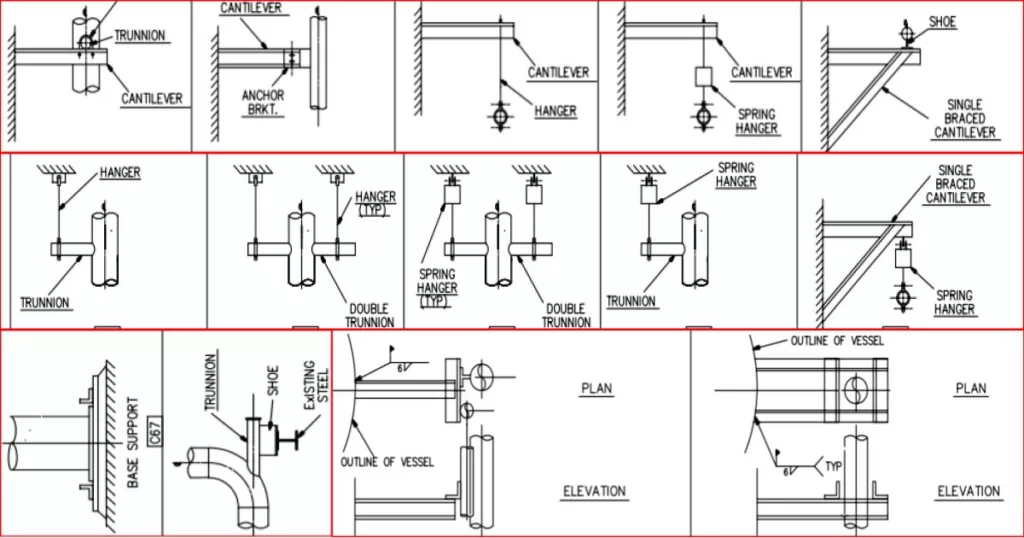

Pipe Hangers

Pipe hangers are support devices that suspend pipes from overhead structures, walls, or other fixed points. They are essential for maintaining the elevation and alignment of pipes, preventing sagging or movement that can lead to stress, vibration, and even failure. Pipe hangers come in various forms, each designed for specific applications. Two of the primary types of pipe hangers are Clevis Hangers and Riser Clamps.

Clevis Hangers

Clevis hangers are a type of pipe hanger widely used for supporting horizontal runs of pipe. They consist of a clevis, a yoke-shaped metal component with holes or pins, and a threaded rod or a hanger rod. Here are some key features and applications of Clevis hangers:

- Adjustability:

- Versatility

- Load Capacity

- Installation

- Common Uses

Riser Clamps

Riser clamps are designed to support vertical runs of pipe, such as those found in high-rise buildings, industrial towers, and utility distribution systems. They are called “riser” clamps because they are often used to support pipes that rise vertically through multiple floors or levels. Here are some important aspects of riser clamps:

- Vertical Support

- Construction

- Materials

- Thermal Considerations

- Load Capacity

- Common Uses

Variable Spring Hangers

Variable spring hangers, also known as variable support hangers, are engineered to address one of the most critical challenges in piping systems: managing thermal expansion and contraction. These hangers provide continuous support while accommodating vertical movement due to temperature fluctuations. Here are some key features and applications of variable spring hangers:

- Load Adjustment

- Thermal Expansion Control

- Versatility

- Installation

- Common Uses

Constant Spring Hangers

Constant spring hangers, in contrast to variable spring hangers, provide a consistent level of support regardless of pipe movement due to temperature changes. They are designed to counteract the force exerted by the weight of the pipe and its contents while maintaining a constant support load. Here are some key considerations for constant spring hangers:

- Steady Support

- Limited Vertical Movement

- Precision Engineering

- Applications

Pipe Shoes and Saddles

Pipe shoes and saddles are support components that provide both load-bearing support and protection to the underside of the pipe. They are commonly used to support horizontal pipes resting on beams, piers, or other structural elements. Two primary types of pipe shoes and saddles are Slide Bearings and Roller Supports.

Slide Bearings

Slide bearings, also known as sliding supports or slide plates, are designed to reduce friction between the pipe and its supporting structure. Here are some important aspects of slide bearings:

- Friction Reduction

- Horizontal Movement

- Materials

- Common Uses

Roller Supports

Roller supports are designed to allow vertical movement of pipes while providing stability and support. They consist of rollers or wheels that the pipe rests on, facilitating both vertical and lateral movement. Here are key considerations for roller supports:

- Vertical Movement

- Low Friction

- Load Capacity

- Applications

Pipe Anchors

Pipe anchors are support devices designed to restrain the movement of pipes in a specific direction, preventing undesired axial movement or lateral motion. Anchors are essential for ensuring the structural integrity of a piping system and safeguarding against vibrations or external forces. There are two primary types of pipe anchors: Horizontal Restraints and Vertical Restraints.

Horizontal Restraints

Horizontal restraints, as the name suggests, are used to restrict the horizontal movement of pipes. They are typically employed in scenarios where pipes need to be prevented from shifting or sliding due to forces such as thermal expansion, seismic activity, or pressure fluctuations. Key aspects of horizontal restraints include:

- Application Specific

- Load Distribution

- Materials and Design

- Common Uses

Vertical Restraints

Vertical restraints are employed to prevent vertical movement or displacement of pipes. They ensure that pipes remain in their designated position and elevation, which is crucial for maintaining alignment and preventing damage to the pipe or its connections. Key considerations for vertical restraints include:

- Load Support

- Alignment Maintenance

- Materials and Mounting

- Common Uses

Pipe Guides

Pipe guides, also known as pipe supports or pipe stands, serve the crucial role of guiding and supporting pipes while allowing for controlled movement in one or more directions. These guides are essential for preventing damage due to thermal expansion, contraction, or other dynamic forces. There are two primary types of pipe guides: Rod Guides and Slide Guides.

Rod Guides

Rod guides are a type of pipe guide that restricts movement in a single direction, typically the axial direction along the length of the pipe. Key features of rod guides include:

- Axial Support

- Alignment

- Materials

- Common Uses

Slide Guides

Slide guides, also known as linear or slide supports, are designed to allow movement of the pipe in both axial and lateral directions. These guides are particularly useful in situations where pipes experience multidirectional forces. Key considerations for slide guides include:

- Multidirectional Movement

- Low Friction

- Materials and Design

- Common Uses

Designing Piping Support Systems

The design of piping support systems is a critical aspect of ensuring the integrity and functionality of pipelines within various industrial and commercial settings. This chapter will explore the key considerations in designing these systems, including load calculation, material selection, and other crucial factors.

Load Calculation

Properly calculating the loads that piping support systems must bear is fundamental to their design. These loads can be broadly categorized into several types:

Dead Load

Dead load refers to the weight of the pipes themselves, along with any fixtures, insulation, and attachments permanently affixed to them. Accurate dead load calculation is crucial because it forms the basis for selecting the appropriate support components and determining their spacing and capacity.

- Pipe Weight: The weight of the pipes depends on their material, size, and wall thickness. Manufacturers provide weight tables for different pipe types.

- Attachments: Consider any valves, fittings, insulation, or instruments attached to the pipe and include their weights.

Live Load

Live load includes the weight of the fluid or material being transported through the pipes and any transient forces applied during operation. Calculating live load involves assessing the maximum expected weight, fluid velocity, and potential hydraulic forces within the system.

- Fluid Weight: Calculate the weight of the fluid by multiplying its density by the flow rate and the volume of fluid within the pipe.

- Hydraulic Forces: Consider forces generated by pressure surges, water hammer, or other hydraulic phenomena that can affect the pipe.

Wind Load

For outdoor or exposed piping, wind load calculations are essential to determine the force exerted by wind on the pipes and support structures. Wind load depends on factors such as the pipe’s diameter, height above ground, and wind speed in the location.

- Wind Speed: Refer to local weather data or engineering standards to determine the expected wind speed for your location.

- Exposure Factor: The degree of exposure and the pipe’s shape can affect the wind load. Factors like terrain and surrounding structures play a role in this calculation.

Seismic Load

In areas prone to earthquakes, seismic load calculations are critical for designing piping support systems that can withstand seismic forces. Seismic load is determined based on the seismic zone, soil conditions, and the pipe’s location within the facility.

- Seismic Zone: Different regions have varying seismic hazard levels. Determine the seismic zone for your location.

- Soil Type: Soil conditions affect how seismic forces are transmitted to the piping system. Consider soil properties when calculating seismic loads.

- Building Category: The building’s occupancy and importance factor also impact the seismic design.

Material Selection

Selecting the appropriate materials for piping support components is crucial for ensuring durability and long-term performance. Material selection is influenced by factors such as the type of pipe, environmental conditions, load capacity requirements, and corrosion resistance. Common materials for support components include:

- Steel

- Aluminum

- FRP (Fiber-Reinforced Plastic)

- Thermoplastics

- Coatings

Material selection should align with the specific needs of the piping system and consider factors like load capacity, exposure to chemicals or harsh weather, and compliance with industry standards and codes.

Support Spacing and Placement

Proper support spacing and placement are crucial for the effective operation of piping support systems. Support components should be strategically located to distribute loads evenly, prevent sagging or excessive deflection, and maintain alignment. Key considerations include:

- Spacing Guidelines

- Consider Loads

- Temperature Effects

- Considerations for Expansion Joints

Thermal Expansion Joints

Thermal expansion and contraction are inherent to piping systems, and thermal expansion joints are crucial for accommodating these movements while preventing stresses and damage to the pipes and support structures. Key considerations for thermal expansion joints include:

- Types of Expansion Joints

- Proper Sizing

- Materials

- Installation

Supporting Insulated Pipes

In applications where pipes are insulated to maintain temperature, supporting insulated pipes requires special consideration. The insulation adds additional weight and thickness to the pipe, which can affect support requirements. Key considerations include:

- Insulation Thickness

- Support Type

- Load Calculation

Special Considerations for High-Temperature Applications

In high-temperature applications, the challenges of designing a piping support system become more complex due to the increased risk of thermal stresses, material degradation, and safety concerns. Here are some special considerations for high-temperature applications:

- Material Selection

- Insulation

- Expansion Joints

- Thermal Movement

- Safety

High-temperature piping systems demand meticulous engineering and adherence to stringent safety standards to ensure both operational efficiency and safety.

Piping Support Codes and Standards

The design and installation of piping support systems are subject to a wide range of codes and standards to ensure the safety, integrity, and reliability of piping infrastructure across various industries. Below, we’ll explore some of the most prominent codes and standards that govern piping support systems.

ASME B31.1 and ASME B31.3

- ASME B31.1: This code, titled “Power Piping,” provides requirements for piping systems used in power plants, including fossil-fueled, nuclear, and other facilities. It covers aspects of design, materials, fabrication, inspection, testing, and more, including guidelines for the design and installation of piping supports.

- ASME B31.3: Titled “Process Piping,” this code is widely used in the chemical, petrochemical, and refining industries. It addresses the design, construction, and maintenance of process piping systems, including piping support systems.

API 650 and API 620

- API 650: The American Petroleum Institute’s API 650 code pertains to the design and construction of welded steel tanks for the storage of liquids. It includes specifications for tank foundations and anchorage systems, which are crucial aspects of tank support.

- API 620: This code, also from the American Petroleum Institute, focuses on the design and construction of large, low-pressure storage tanks. It provides requirements for tank foundations and anchor bolts, emphasizing stability and safety.

AISC 360

The American Institute of Steel Construction (AISC) 360 specification governs the design of steel structures, including those used in support systems for piping. It outlines design criteria, material specifications, fabrication and erection requirements, and considerations for structural stability.

NFPA 13 and NFPA 14

- NFPA 13: The National Fire Protection Association’s NFPA 13 standard is concerned with the installation of sprinkler systems in buildings. It includes guidelines for the support and bracing of piping systems, ensuring their reliability in fire protection applications.

- NFPA 14: This NFPA standard addresses the installation of standpipe and hose systems for fire protection. It provides requirements for the support and hanger spacing of pipes used in these systems.

International Building Code (IBC)

The International Building Code (IBC) is a widely adopted building code that provides comprehensive regulations for building design, construction, and safety. It includes provisions for the design and installation of piping systems, including support and hanger requirements, ensuring compliance with structural and safety standards.

European Standards (EN)

In Europe, European Standards (EN) govern various aspects of piping systems, including piping support design. These standards are developed by the European Committee for Standardization (CEN) and provide guidelines for materials, design, fabrication, installation, and testing of piping systems across different industries.

Installation and Maintenance

The proper installation of piping support systems is essential to ensure their functionality, safety, and longevity. In this chapter, we’ll explore installation best practices, including alignment and leveling, fastening and clamping, and the importance of inspections during installation.

Installation Best Practices

Alignment and Leveling

Alignment and leveling are critical aspects of piping support system installation. Proper alignment ensures that pipes are positioned correctly relative to their supports and connected components. Leveling ensures that the pipe is in the correct horizontal plane. Key considerations include:

- Survey and Layout.

- Alignment Tools

- Leveling Instruments

- Adjustability

- Preliminary Checks

Fastening and Clamping

The fastening and clamping of support components to the structure and pipes is critical for maintaining the integrity of the piping support system. Consider the following best practices:

- Proper Fasteners

- Torque Specifications

- Cushioning and Insulation

- Load Distribution

- Prevent Slippage

Inspection during Installation

Inspection during installation is a critical step to catch any errors or issues before they become problematic. This proactive approach helps identify and rectify installation issues early in the process. Key considerations include:

- Visual Inspection

- Level and Plumb

- Alignment Check

- Load Testing

- Documentation

- Safety Precautions

- Quality Control

Routine Maintenance

Routine maintenance is a key aspect of ensuring the continued reliability and safety of piping support systems. This chapter explores the various components of routine maintenance, including inspection, lubrication, and the importance of timely repairs and replacements.

Inspection

Regular inspection of piping support systems is crucial for identifying signs of wear, damage, or misalignment. Here are some important considerations for inspections:

- Frequency

- Visual Checks

- Alignment Verification

- Load Assessment

- Vibration Analysis

- Documentation

- Non-destructive Testing (NDT)

Lubrication

Lubrication is essential for the proper functioning of moving parts within a piping support system. Here are key points to consider for lubrication:

- Lubrication Points

- Lubricant Selection

- Regular Lubrication

- Cleanliness

- Quantity

- Record Keeping

Repairs and Replacements

Prompt repairs and replacements are essential when maintenance inspections reveal issues or when components reach the end of their service life. Consider the following:

- Timely Repairs

- Component Life Expectancy

- Spare Parts

- Professional Expertise

- Record of Repairs

Key Takeaways for pipeline supports

- Piping support systems play a crucial role in various industries by ensuring the integrity, safety, and reliability of pipelines that transport fluids and materials under various conditions.

- Different types of piping supports, including hangers, anchors, guides, and expansion joints, are designed to address specific challenges such as load distribution, thermal expansion, vibration control, and maintenance accessibility.

- Proper design, material selection, support spacing, and anchoring are essential elements in creating effective piping support systems.

- Routine maintenance, including inspection, lubrication, and timely repairs or replacements, is critical to preventing failures and ensuring the longevity of support systems.

- Compliance with industry codes and standards is fundamental to achieving safe and reliable piping support systems.

- Real-world case studies highlight the consequences of support failures, successful implementations, and valuable lessons learned.

- Future trends in piping support include innovative technologies such as smart support systems, 3D printing, sustainable practices, and advances in materials and manufacturing.

Download PDF here – Piping Support: Types, Purpose, Design, Codes PDF