What is a Pressure Reducing Valve (PRV)?

A Pressure Reducing Valve (PRV), also known as a Pressure Regulator Valve or Pressure Control Valve, is a mechanical device used to control and regulate the pressure of fluids (liquids or gases) within a system. Its primary purpose is to reduce and maintain the pressure at a desired and safe level downstream, even when the inlet pressure fluctuates.

The full form of PRV is Pressure Reducing Valve.

Why Pressure Management Matters

Pressure management is of utmost importance in various industrial and residential applications for several compelling reasons:

- Equipment Safety and Longevity

- Safety in Everyday Life

- Safety and Compliance

- Optimized Performance

- Environmental Impact

- Energy Efficiency

- Water Conservation

- System Reliability

- Fire Protection:

- Process Control

- Cost Savings

How Does a PRV Work?

A PRV operates on a straightforward principle. It consists of an adjustable spring-loaded diaphragm and a valve. Here’s how it works:

- Inlet Pressure: The fluid enters the PRV from the high-pressure side (inlet).

- Diaphragm and Spring: Inside the PRV, a diaphragm is exposed to the incoming pressure. This diaphragm is preloaded with a spring, which exerts force on it.

- Valve Mechanism: When the inlet pressure exceeds the desired setpoint (as adjusted by the spring tension), the diaphragm is pushed against the spring force. This causes the valve to close partially or completely, reducing the flow of fluid.

- Outlet Pressure: As a result of valve adjustment, the pressure downstream (outlet) is maintained at the desired level. When the inlet pressure decreases, the diaphragm releases the valve, allowing more fluid to pass through and maintain the set outlet pressure.

The Importance of Pressure Regulation

Pressure regulation is vital for several reasons:

- Pressure Regulation: PRVs are primarily designed to regulate and control the pressure of fluids (liquids or gases) within a system. They ensure that the pressure downstream remains at a safe and specified level, even when the inlet pressure fluctuates.

- Equipment Protection: PRVs help protect downstream equipment and components from damage caused by excessive pressure. By maintaining a consistent pressure level, they prevent overpressure situations that can lead to leaks, bursts, or equipment failure.

- Energy Efficiency: Proper pressure regulation with PRVs can contribute to energy efficiency. By reducing pressure to the optimal level required for a particular process or application, PRVs help minimize energy consumption and associated costs.

- Water Conservation: In applications such as residential water supply and irrigation, PRVs play a vital role in conserving water. By reducing the pressure to a suitable level, they prevent water wastage and promote sustainable water use.

- Safety: PRVs enhance the safety of systems by preventing pressure-related accidents. In situations where high-pressure conditions could pose a risk, such as in steam systems or industrial processes, PRVs act as safety devices to maintain safe operating pressures.

- Controlled Flow: PRVs enable precise control of fluid flow rates. This is valuable in various industrial processes, where maintaining a specific flow rate is critical for product quality and consistency.

- Safety: Pressure regulation is often critical for ensuring compliance with safety standards and regulations. Many industries have strict guidelines regarding pressure levels to prevent accidents and protect workers.

- Environmental Impact: Uncontrolled pressure can result in leaks, spills, and environmental damage, especially in industries like oil and gas. Pressure regulation helps mitigate these risks and reduce environmental impact.

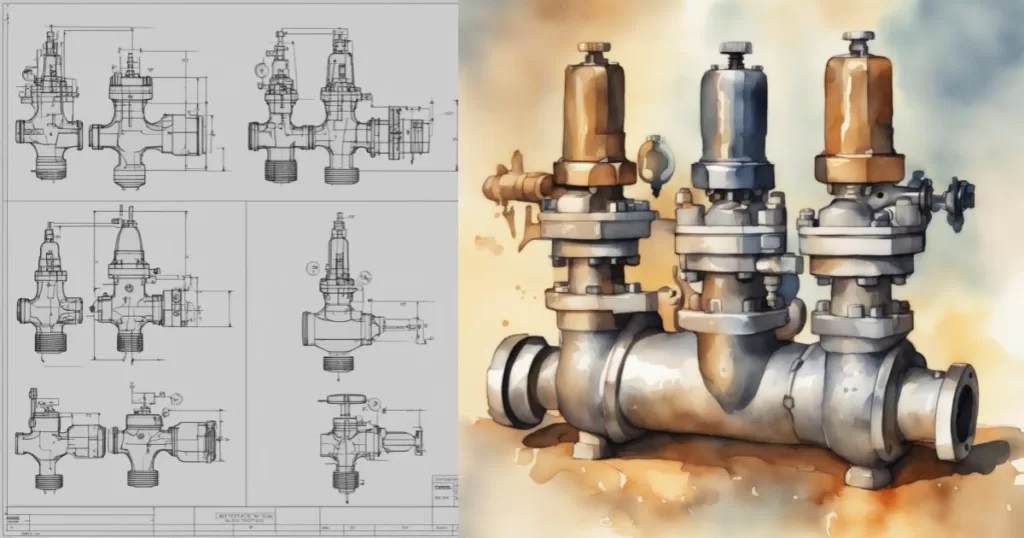

Pressure Reducing Valves (PRV) P and ID symbol

Types of Pressure Reducing Valves (PRV)

They come in a variety of types, each designed for specific purposes. We different types of Pressure Reducing Valves in a sequential manner to provide a comprehensive understanding of their functionalities.

Direct-acting Pressure Reducing Valves:

- Pilot-Operated Direct-Acting PRVs

- Piston-Type Direct-Acting PRVs

- Diaphragm-Type Direct-Acting PRVs

Pilot-Operated Pressure Reducing Valves:

- Single-Port Pilot-Operated PRVs

- Double-Port Pilot-Operated PRVs

- Balanced Pilot-Operated PRVs

- Unbalanced Pilot-Operated PRVs

Spring-Loaded Pressure Reducing Valves:

- Standard Spring-Loaded PRVs

- High-Pressure Spring-Loaded PRVs

- Low-Pressure Spring-Loaded PRVs

Temperature-Controlled Pressure Reducing Valves:

- Thermostatic Pressure Reducing Valves

- Balanced Pressure Thermostatic Valves

- Unbalanced Pressure Thermostatic Valves

Proportional Pressure Reducing Valves:

- Electrically Controlled Proportional PRVs

- Pneumatically Controlled Proportional PRVs

- Hydraulically Controlled Proportional PRVs

Adjustable Pressure Reducing Valves:

- Manual Adjustable PRVs

- Remote Adjustable PRVs

- Automatic Adjustable PRVs

Applications of Pressure Reducing Valves

Pressure reducing valves (PRVs), also known as pressure regulators, are essential components in various industries and applications where precise control of fluid pressure is required. Here are some common applications of pressure reducing valves:

- Steam boilers

- Pneumatic systems

- Hydraulic systems

- Irrigation systems

- Chemical processing

- Industrial processes

- Oil and gas pipelines

- Municipal water supply

- Aerospace applications

- Fire protection systems

- Power generation plants

- Water distribution systems

- Pharmaceutical manufacturing

- Food and beverage production

- HVAC (Heating, Ventilation, and Air Conditioning) systems

Benefits of Using Pressure Reducing Valves

- Cost savings

- Leak prevention

- System efficiency

- Equipment protection

- Safety enhancement

- Water conservation

- Energy conservation

- Reduced maintenance

- Pressure stabilization

- Extended equipment lifespan

Installation and Maintenance Tips

Certainly, here are installation and maintenance tips for Pressure Reducing Valves (PRVs):

Proper PRV Installation:

- Location: Choose an appropriate location for the PRV that is easily accessible for maintenance. Ensure it is installed as close as possible to the point of use to maintain accurate pressure regulation.

- Orientation: Install the PRV in the correct orientation as indicated by the manufacturer, typically with the arrow pointing in the direction of flow.

- Pipe Support: Use proper pipe supports to prevent undue stress on the PRV and ensure that the valve and surrounding pipes are adequately supported.

- Strainer Installation: If a strainer is required, install it upstream of the PRV to protect the valve from debris and contaminants.

- Pressure Gauges: Install pressure gauges upstream and downstream of the PRV to monitor the pressure differentials and ensure the valve is functioning correctly.

- Safety Valves: In high-pressure systems, consider installing a safety relief valve downstream of the PRV to protect against overpressure situations.

- Piping Material: Use appropriate piping materials that are compatible with the fluid being regulated to prevent corrosion and leaks.

Routine Maintenance Practices:

- Regular Inspection: Periodically inspect the PRV for signs of wear, corrosion, or damage. Look for leaks around the valve body.

- Cleaning: Clean the valve and its components to remove any accumulated dirt, scale, or debris that may affect its performance.

- Lubrication: If your PRV requires lubrication, follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Pressure Adjustment: If you have an adjustable PRV, periodically check and adjust the set pressure to ensure it remains within the desired range.

- Testing: Conduct regular pressure tests to confirm that the PRV is maintaining the correct pressure downstream. Compare readings with pressure gauges.

- Drainage: Ensure that any condensate or moisture is properly drained from the system to prevent damage to the PRV and associated components.

Download here-

Pressure Reducing Valve: Types, Applications, and Benefits PDF

Troubleshooting Common Issues:

- Pressure Fluctuations: If you’re experiencing pressure fluctuations downstream, check for debris or scale buildup in the PRV. Clean or replace components as needed.

- Leaking Valve: Leaks around the valve body can indicate worn seals or damaged components. Inspect the valve for wear and replace parts if necessary.

- Incorrect Pressure: If the PRV is not maintaining the desired pressure, check for blockages in the pilot system (for pilot-operated PRVs) or adjust the spring tension (for direct-acting PRVs).

- Noise and Vibration: Unusual noise or vibration may indicate problems with the valve. Inspect for loose parts, misalignment, or damaged components.

- Frozen Valve: In cold climates, PRVs can freeze. Install insulation or heat tracing to prevent freezing or consider using freeze-resistant PRVs in such conditions.

- Safety Valve Activation: If a safety relief valve downstream of the PRV frequently activates, it may indicate an issue with the PRV, such as a malfunctioning pilot system. Investigate and address the root cause.

Always refer to the manufacturer’s installation and maintenance guidelines specific to your PRV model, as recommendations may vary. Regular maintenance and prompt troubleshooting can help ensure the continued reliable operation of your Pressure Reducing Valve.

Choosing the Right Pressure Reducing Valve

Choosing the right Pressure Reducing Valve (PRV) is crucial to ensure it performs effectively in your specific application. Here are the factors to consider and sizing and selection guidelines:

Factors to Consider:

- System Type: Determine the type of system the PRV will be used in, whether it’s a residential water supply, industrial process, or fire protection system. Different systems may have varying pressure requirements.

- Inlet Pressure Range: Know the range of inlet pressures the PRV will encounter. Ensure the selected valve can handle the maximum and minimum pressures within the system.

- Outlet Pressure Requirement: Determine the desired outlet pressure or pressure range needed for your application. This is a critical factor in selecting the right PRV.

- Flow Rate: Calculate the maximum flow rate (in gallons per minute, cubic meters per hour, etc.) the PRV will need to handle. Oversized or undersized valves can lead to inefficiencies.

- Fluid Type: Consider the type of fluid (liquid or gas) that the PRV will be regulating. Different fluids may require specific materials or valve designs to prevent corrosion or contamination.

- Temperature Range: Ensure that the PRV is rated to handle the temperature range of the fluid it will be in contact with. Extreme temperatures can affect valve performance.

- Valve Material: Select materials compatible with the fluid being regulated to prevent corrosion or contamination. Common materials include brass, stainless steel, and bronze.

- Adjustability: Decide whether an adjustable or non-adjustable PRV is needed. Adjustable PRVs allow you to fine-tune the outlet pressure, while non-adjustable ones are set at the factory.

- Installation Space: Consider the available space for installation, including clearance requirements and pipe layout. Ensure there’s enough room to install the chosen PRV properly.

Sizing and Selection Guidelines:

- Calculate Flow Rate: Determine the maximum flow rate the PRV needs to handle. This can be calculated based on the size of the system and the expected demand.

- Pressure Drop: Calculate the expected pressure drop across the PRV. This helps ensure that the valve can effectively reduce pressure while maintaining the desired outlet pressure.

- Select Valve Type: Choose between direct-acting and pilot-operated PRVs based on your specific application. Pilot-operated PRVs are often used for high-flow industrial systems, while direct-acting PRVs are suitable for smaller residential applications.

- Check Manufacturer Specifications: Review the manufacturer’s specifications and performance curves for PRVs you’re considering. Look for valves that match your calculated flow rate and pressure requirements.

- Consider Safety: In applications where safety is a concern, such as steam systems or fire protection, consider using redundant PRVs or safety relief valves downstream of the PRV for added protection against overpressure situations.

- Consult with Experts: If you’re unsure about the sizing and selection process, consider consulting with a knowledgeable engineer or a representative from the PRV manufacturer for guidance.

By carefully considering these factors and following sizing and selection guidelines, you can choose the right Pressure Reducing Valve that best suits your application’s needs, ensuring efficient and reliable pressure regulation.

FAQs on Pressure Reducing Valves:

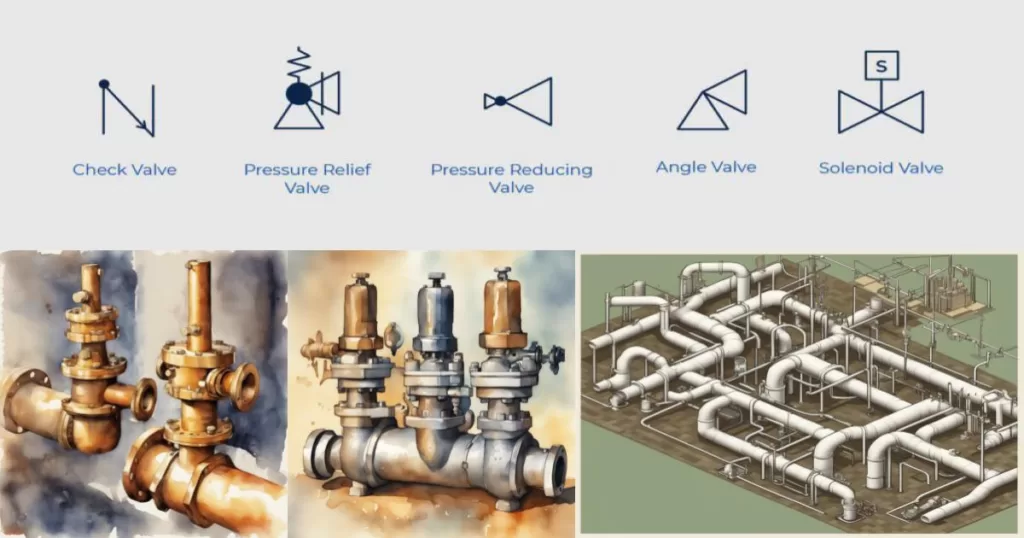

What is the difference between a Pressure Reducing Valve (PRV) and a Pressure Relief Valve (PRV)?

Here’s a comparison between a Pressure Reducing Valve (PRV) and a Pressure Relief Valve (PRV) in chart format:

| Aspect | Pressure Reducing Valve (PRV) | Pressure Relief Valve (PRV) |

| Purpose | Reduces and maintains a set pressure in a system. | Releases excess pressure to prevent over-pressurization. |

| Function | Regulates incoming pressure to a lower, desired level. | Opens to vent or release pressure when it exceeds a specific setpoint. |

| Normal Position | Closed or partially open, maintaining pressure downstream. | Closed, preventing any pressure release under normal conditions. |

| Set Pressure | Adjustable to a predetermined lower pressure. | Set to open at a specific, higher pressure level. |

| Location | Installed downstream in the system where pressure reduction is needed. | Typically installed upstream in the system to protect against overpressure. |

| Pressure Control | Maintains a constant, lower pressure within the system. | Activates only when pressure exceeds a preset limit, then closes when pressure is reduced. |

| Common Applications | Water distribution systems, HVAC, irrigation, and industrial processes. | Boiler systems, pipelines, and tanks to prevent catastrophic failures. |

| Direction of Flow | Reduces pressure in the direction of flow. | Releases pressure to the atmosphere. |

| Safety Function | Prevents pressure from becoming too high in downstream equipment. | Protects equipment and pipelines from damage due to excessive pressure. |

| Maintenance | Regular inspection and adjustment may be required. | Periodic testing and maintenance to ensure proper operation. |

| Symbols |

Please note that the term “PRV” can stand for both Pressure Reducing Valve and Pressure Relief Valve depending on the context, so it’s important to clarify which type of PRV is being discussed.

What should I do if my PRV is making unusual noises?

Unusual noises like whistling or chattering can indicate issues with the PRV. It’s best to have a professional inspect and troubleshoot the valve to identify and rectify the problem.

Can I adjust the outlet pressure of an non-adjustable PRV?

No, non-adjustable PRVs have a fixed outlet pressure set at the factory and cannot be manually adjusted. If you need to change the outlet pressure, you would need to replace the PRV with an adjustable one.

When it comes to Pressure Reducing Valves (PRVs), there are several important codes and standards that govern their design, installation, and use. These codes and standards vary by region and application, so it’s essential to consult the specific codes relevant to your location and industry. Below are some of the key international and national standards and codes often associated with PRVs:

Important codes and standards Pressure Reducing Valve

- ASME Boiler and Pressure Vessel Code: ASME BPVC contains various sections that address different types of pressure vessels and related equipment, including Section VIII, which covers Pressure Vessels. PRVs used in pressure vessel applications are typically subject to this code.

- API 526: This standard published by the American Petroleum Institute (API) provides specifications for Pressure-Relieving and Depressuring Systems, including PRVs used in the oil and gas industry.

- ANSI/ISA-75.01.01: The International Society of Automation (ISA) standardizes the symbols and identification for control and instrumentation devices, including PRVs. This standard helps ensure consistent labeling and documentation.

- ISO 4126: The International Organization for Standardization (ISO) has developed a series of standards related to safety devices for protection against excessive pressure. ISO 4126 covers safety valves, including PRVs.

- ASME B16.34: This standard by ASME specifies requirements for valve design, materials, and testing. It is often referenced when selecting PRVs for specific applications.

- NFPA 30: The National Fire Protection Association (NFPA) code for flammable and combustible liquids includes requirements for pressure relief devices like PRVs to prevent overpressure situations in storage tanks.

- API RP 520: This recommended practice by API provides guidance on the installation, inspection, and maintenance of pressure-relieving devices, including PRVs, in process industries.

- ISA-TR96.05.01: An ISA technical report that provides guidance on the terminology, concepts, and evaluation of safety instrumented functions, including those involving PRVs.

-

EN 12516: This European standard covers industrial valves, including safety and relief valves. It provides requirements for the design, testing, and selection of PRVs for various applications.

Important formula Pressure Reducing Valve only

Here are some important formulas related to Pressure Reducing Valves (PRVs):

- Pressure Drop Across PRV:

- ΔP = P1 – P2

- ΔP is the pressure drop across the PRV.

- P1 is the inlet pressure (upstream pressure).

- P2 is the outlet pressure (downstream pressure).

- Flow Rate Through PRV:

- Q = Cv √(ΔP/SG)

- Q is the flow rate through the PRV.

- Cv is the valve flow coefficient.

- ΔP is the pressure drop across the PRV.

- SG is the specific gravity of the fluid.

- Valve Flow Coefficient (Cv):

- Cv = Q / √(ΔP/SG)

- Cv is the valve flow coefficient.

- Q is the flow rate through the PRV.

- ΔP is the pressure drop across the PRV.

- SG is the specific gravity of the fluid.

- Valve Sizing for Gas Service (Cg):

- Cg = Cv * √(P1 / T1)

- Cg is the valve sizing coefficient for gas service.

- Cv is the valve flow coefficient.

- P1 is the inlet pressure (absolute) in psia.

- T1 is the absolute temperature in Rankine.

- Valve Sizing for Liquid Service (Cv-L):

- Cv-L = Cv * √(ρ)

- Cv-L is the valve sizing coefficient for liquid service.

- Cv is the valve flow coefficient.

- ρ is the density of the liquid in lb/ft³.

- Valve Setpoint Adjustment:

- P2 = P1 – ΔP

- P2 is the desired outlet pressure (setpoint).

- P1 is the inlet pressure (upstream pressure).

- ΔP is the desired pressure drop across the PRV.

These formulas are used in the sizing, selection, and operation of Pressure Reducing Valves to ensure they function effectively in various applications and systems.