Stainless Steel SS 316 Bolts Weight Chart

Here present a comprehensive stainless steel SS 316 bolts weight chart. Whether you’re a professional in the construction industry or a DIY enthusiast, this chart will provide you with the accurate weight details you need. It is commitment to providing accurate and reliable information, and this weight chart is no exception. We understand the importance of precision in your projects, and that’s why we’ve carefully compiled this chart using data from trusted sources. With this information at your fingertips, you can confidently make decisions about the right bolts for your specific applications. Stainless steel bolts are known for their strength, durability, and resistance to corrosion, making them a popular choice for a wide range of industries. But choosing the right bolts also means considering their weight, especially when dealing with large-scale projects. Don’t waste time guessing or approximating the weight of stainless steel bolts. Let our weight chart guide you to make informed choices and ensure the success of your projects. Read on to discover the weight details of stainless steel SS 316 bolts.

Why Weight Matters in Bolt Selection

Choosing the right bolt for a job might seem like a small detail, but it’s a crucial decision that directly impacts safety and performance. One key factor to consider is the weight. The weight of the bolt itself may not be much, but when multiplied across numerous bolts in a structure, it adds up. This weight affects the overall load-bearing capacity of the structure and can influence its stability. When selecting bolts, it’s essential to factor in the weight they will bear and choose ones that can handle the load effectively. This not only ensures the structural integrity of your project but also contributes to its overall safety and longevity. So, paying attention to the weight capacity of bolts is not just a technical detail but a practical and safety-conscious consideration in any construction or assembly endeavor.

Density of SS 316 Stainless Steel

Stainless Steel 316 (SS 316) is a commonly used austenitic stainless steel with excellent corrosion resistance, particularly in chloride environments. The density of SS 316 stainless steel is approximately 8.0 g/cm³ (grams per cubic centimeter).

Note: The density value provided is an approximation, and actual values may vary slightly depending on specific manufacturing processes and alloy compositions.

I understand that the weight of bolts is calculated based on their density, and there is an approximate tolerance of 5% (+/-). This means that the calculated weight may vary by up to 5% from the nominal value. When performing any calculations or making decisions based on these weights, it’s important to consider this margin of error.

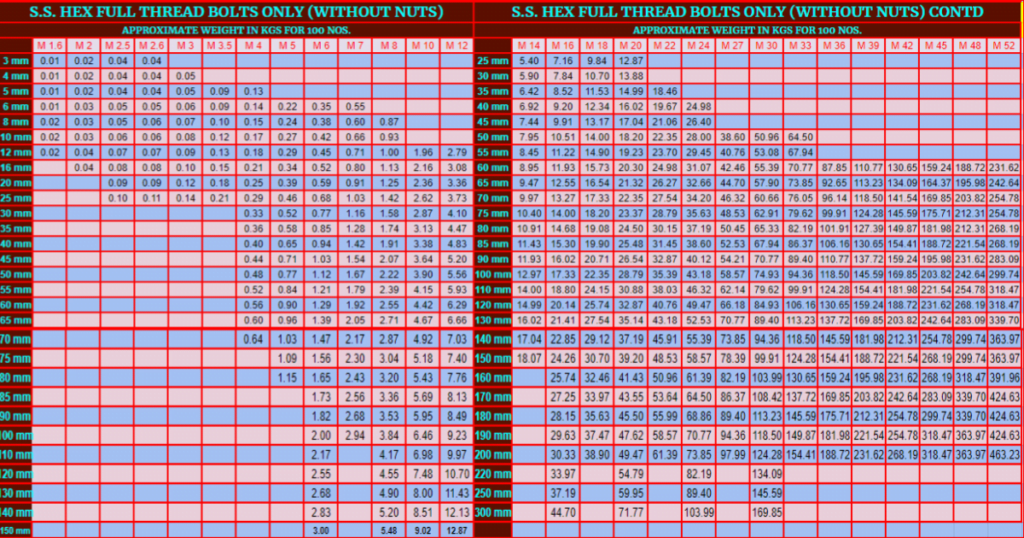

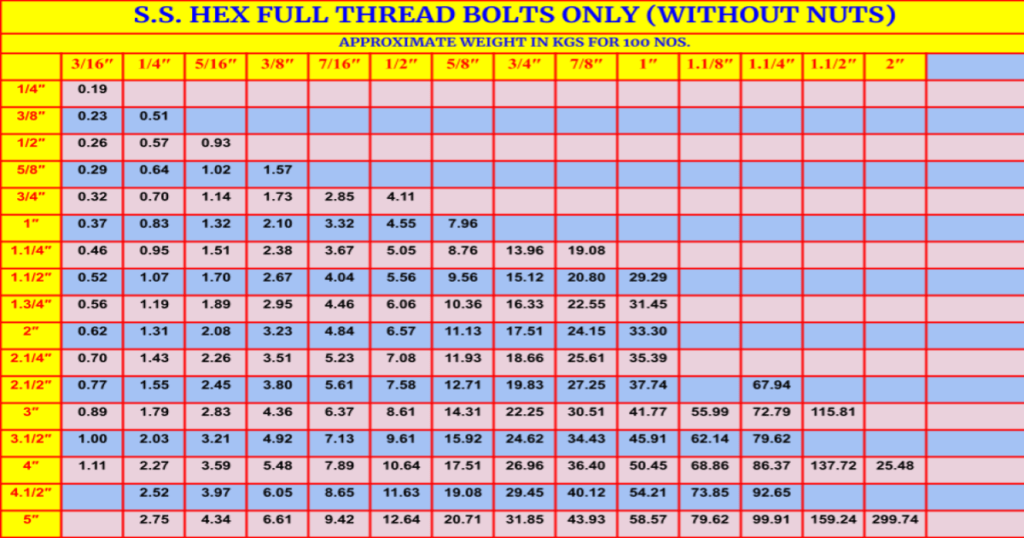

S.S. HEX FULL THREAD BOLTS ONLY (WITHOUT NUTS)

Note- I understand that the weight of bolts is calculated based on their density, and there is an approximate tolerance of 5% (+/-). This means that the calculated weight may vary by up to 5% from the nominal value. When performing any calculations or making decisions based on these weights, it’s important to consider this margin of error.

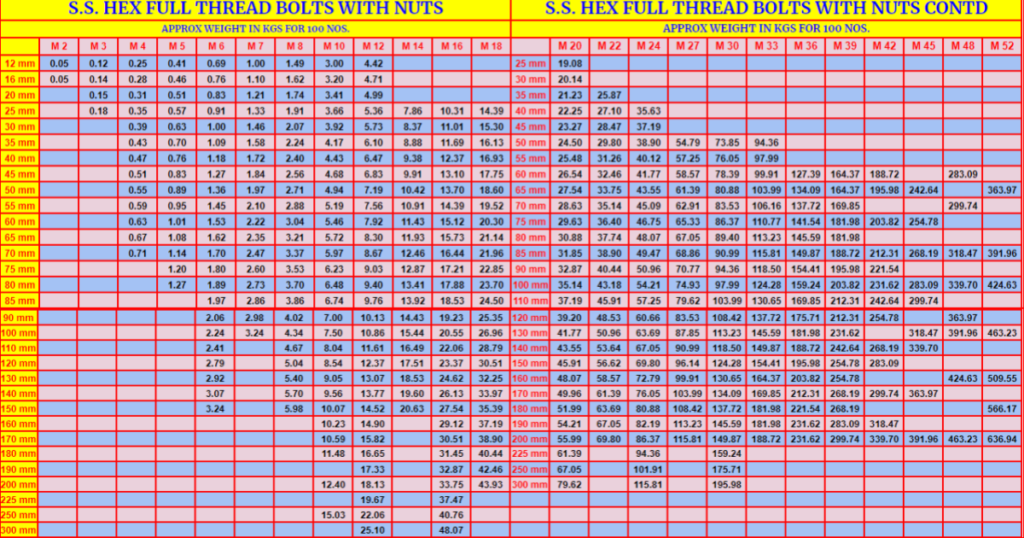

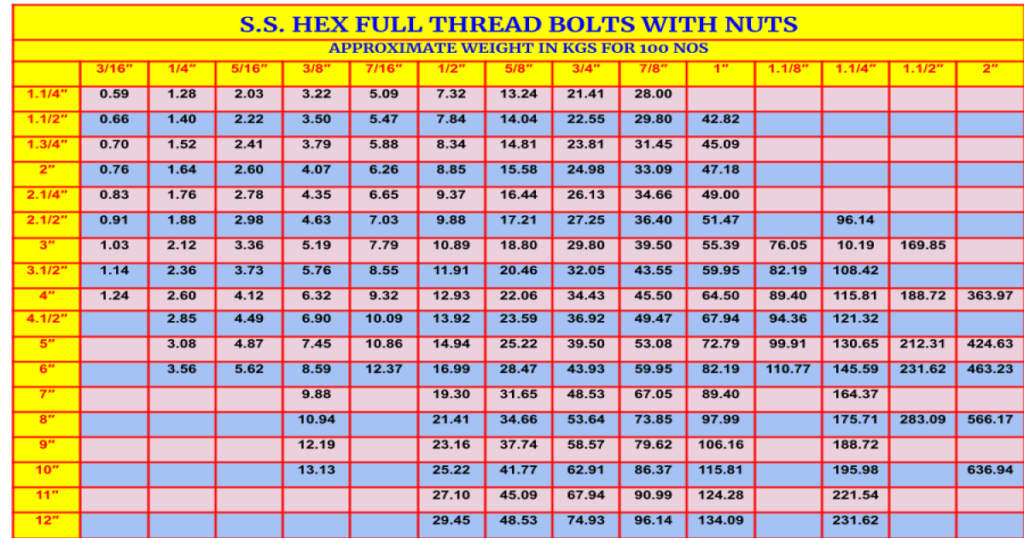

SS 316 HEX FULL THREAD BOLTS WEIGHT (WITH NUTS)

Note – I understand that the weight of bolts is calculated based on their density, and there is an approximate tolerance of 5% (+/-). This means that the calculated weight may vary by up to 5% from the nominal value. When performing any calculations or making decisions based on these weights, it’s important to consider this margin of error.

SS 316 HEX FULL THREAD BOLTS WEIGHT (WITHOUT NUTS)

Stainless Steel Grade Density

| Stainless Steel Grade | Density (g/cm³) |

|---|---|

| Stainless steel 301 | 7.93 |

| Stainless steel 302 | 7.93 |

| Stainless steel 303 | 7.93 |

| Stainless steel 304 | 7.93 |

| Stainless steel 304L | 7.93 |

| Stainless steel 309 | 7.89 |

| Stainless steel 310 | 7.89 |

| Stainless steel 316 | 7.98 |

| Stainless steel 316L | 7.98 |

| Stainless steel 321 | 7.92 |

| Stainless steel 347 | 7.92 |

| Stainless steel 410 | 7.75 |

| Stainless steel 430 | 7.7 |

Decoding the Weight Chart for SS 316 Bolts

The weight chart helps us understand how heavy these bolts are. Stainless steel SS 316 is a type of metal that’s strong and resistant to rust. The weight of the bolts depends on their size, and the chart shows us this information. Imagine you have a bunch of SS 316 bolts of different sizes, like small, medium, and large. The weight chart tells you how much each bolt weighs based on its size. This is important because when you’re working on a project, you need to know how heavy the bolts are to make sure they’re suitable for your job. If you’re working on something that requires lighter bolts, you can easily find that information in the chart. It’s like having a roadmap for choosing the perfect bolts for your project, making your work easier and more efficient.

Factors Affecting SS 316 Bolt Weight

The weight of SS 316 bolts, which are made of stainless steel, is influenced by various factors. One key factor is the bolt’s size and dimensions; larger bolts generally weigh more than smaller ones. The type of stainless steel used also plays a role, as different grades have varying densities. Additionally, the bolt’s design and shape contribute to its weight. Factors such as the head style, thread length, and overall length impact the overall weight of the bolt. Coatings or finishes applied to the bolt for corrosion resistance can also add to its weight. Therefore, when considering the weight of SS 316 bolts, it’s essential to take into account these factors, including size, stainless steel grade, design, and any additional coatings.

Reading and Using the Weight Chart Effectively

A weight chart is like a map for your health journey. It shows you where you are and where you want to be. Imagine it as your guide to a healthier you. The chart usually has numbers representing your weight at different points. Start by finding your current weight on the chart. Then, look for a healthy range that suits you. It’s not just about the numbers but about feeling good. If you’re aiming to lose or gain weight, set realistic goals and take small steps. The weight chart is a tool, not a strict rule. Use it as a friend to guide you on your path to a happier and healthier lifestyle.

Benefits of Utilizing Stainless Steel SS 316 Bolts

Using Stainless Steel SS 316 bolts comes with a bunch of great perks. First off, they’re like superheroes against rust and corrosion, thanks to their top-notch stainless steel composition. So, whether you’re dealing with rainy weather or a humid environment, these bolts stay strong and sturdy.

Another cool thing is their versatility. These bolts are like the Swiss Army knives of fasteners – they work well in various situations. Whether you’re fixing something at home or working on a big project, SS 316 bolts have got your back.

Durability is their middle name. Seriously, these bolts are tough cookies. They can handle heavy loads and harsh conditions without breaking a sweat. So, if you want something that lasts, these bolts are a solid choice.

Lastly, let’s talk about the low maintenance vibe. SS 316 bolts don’t demand a lot from you. They’re low-maintenance buddies that won’t give you a headache. Easy to use, tough as nails, and rust-resistant – what more could you ask for in a bolt?

Applications Across Industries

Stainless steel 316 bolts are like the superheroes of the fastener world, finding their way into various industries for different tasks. These bolts are like the heavy-duty workers that don’t shy away from tough jobs. From marine applications where they resist corrosion in salty waters, to the food industry where their non-reactive nature ensures safety, SS 316 bolts are versatile. In chemical plants, they stand strong against harsh substances, and in construction, they provide a reliable grip. Think of them as the go-to problem solvers, ensuring things stay together securely, no matter the industry. So, whether you’re building, maintaining, or fixing something, chances are SS 316 bolts have got your back!

Debunking Common Misconceptions About Bolt Weight

Let’s clear up some common misunderstandings about the weight of bolts. People often think that heavier bolts are always stronger, but that’s not necessarily true. The strength of a bolt depends on its material and design, not just its weight. Lightweight bolts can be just as strong or even stronger than heavier ones if they are made from high-quality materials. Another misconception is that all bolts of the same size and type weigh the same, but factors like alloy composition and manufacturing processes can lead to variations in weight. So, it’s essential to consider the specific requirements of your project and choose bolts based on their strength characteristics rather than just their weight. Remember, it’s not always about the heaviest bolt; it’s about the right bolt for the job.

Stainless Steel Bolts: Codes and Standards Across Grades

Stainless steel bolts are subject to various codes and standards to ensure their quality and performance. The most common standards for stainless steel bolts are set by organizations like ASTM International and the International Organization for Standardization (ISO). Here are some commonly used standards and grades:

- ASTM Standards:

- ASTM A193: This standard covers alloy and stainless steel bolting materials for high-temperature or high-pressure service. Grades within A193 include B8 (Class 1 and 2), B8M (Class 1 and 2), and more.

- ASTM A320: Similar to A193, A320 covers alloy and stainless steel bolting materials for low-temperature service. Grades include B8 (Class 1 and 2), B8M (Class 1 and 2), and more.

- ISO Standards:

- ISO 3506: This standard specifies the mechanical properties of corrosion-resistant stainless steel fasteners. It is divided into several parts, each addressing a specific type of stainless steel and its properties. For example, ISO 3506-1 covers A2 stainless steel, and ISO 3506-2 covers A4 stainless steel.

- SAE Standards:

- SAE J429: This standard covers the mechanical and material requirements for inch-series steel bolts, screws, studs, and nuts. While it is not specific to stainless steel, it provides general guidelines for bolt grades.

- DIN Standards:

- DIN EN 3506: This European standard is similar to ISO 3506 and specifies the mechanical properties of corrosion-resistant stainless steel fasteners.

It’s crucial to note that specific grades of stainless steel bolts are designed for different applications and environments. Common stainless steel grades include 18-8 (e.g., 304 and 316), which are widely used in various industries due to their corrosion resistance.

When selecting stainless steel bolts, it’s essential to adhere to the applicable standards and choose the right grade based on factors such as corrosion resistance, temperature requirements, and the intended application. Always refer to the latest versions of the standards for the most up-to-date information.

Conclusion and Final Thoughts

In conclusion, the weight of SS 316 bolts is a critical consideration in bolt selection. Armed with knowledge about weight charts, factors affecting weight, and the benefits of stainless steel SS 316 bolts, you can confidently choose the right bolts for your project. Understanding their applications across industries and dispelling misconceptions ensures informed decision-making. If you have further questions, the FAQs section provides additional clarity. Ultimately, prioritizing the weight factor leads to successful and durable project outcomes.