ASTM A216 Gr WCB

Welcome to our comprehensive guide on ASTM A216 Gr WCB! If you’re looking for a reliable and versatile material for your next industrial project, you’ve come to the right place. In this guide, we’ll delve into the world of ASTM A216 Gr WCB and explore its properties, applications, and benefits. ASTM A216 Gr WCB is a carbon steel casting grade that offers exceptional strength, durability, and corrosion resistance. It is widely used in various industries, including oil and gas, petrochemical, power generation, and more. We’ll walk you through the chemical composition, mechanical properties, and heat treatment processes that make ASTM A216 Gr WCB a top choice for demanding applications. Whether you’re a professional engineer, a project manager, or simply curious about materials, this guide will provide you with valuable insights and practical knowledge to help you make informed decisions. So, let’s dive in and discover everything you need to know about ASTM A216 Gr WCB!

Properties and Composition of ASTM A216 Gr WCB

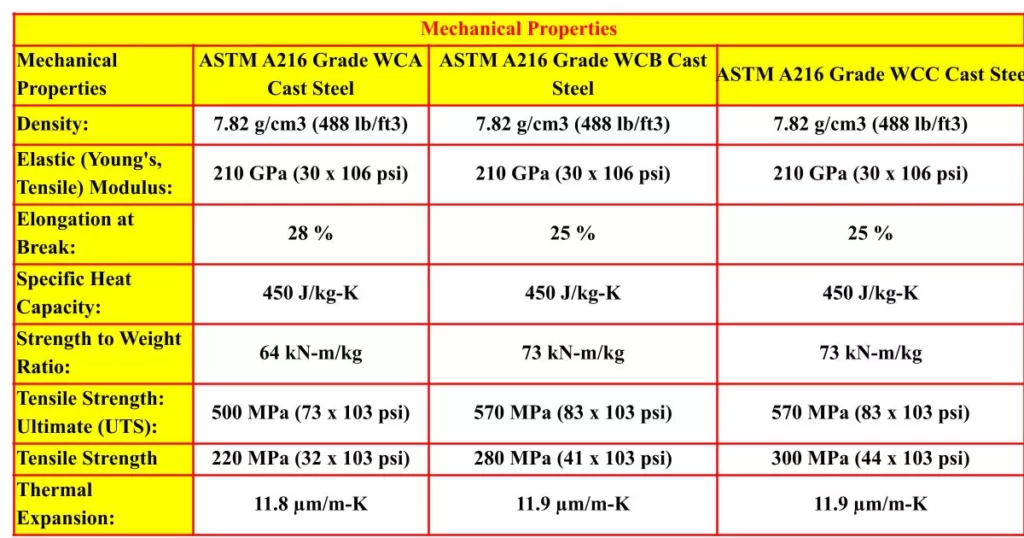

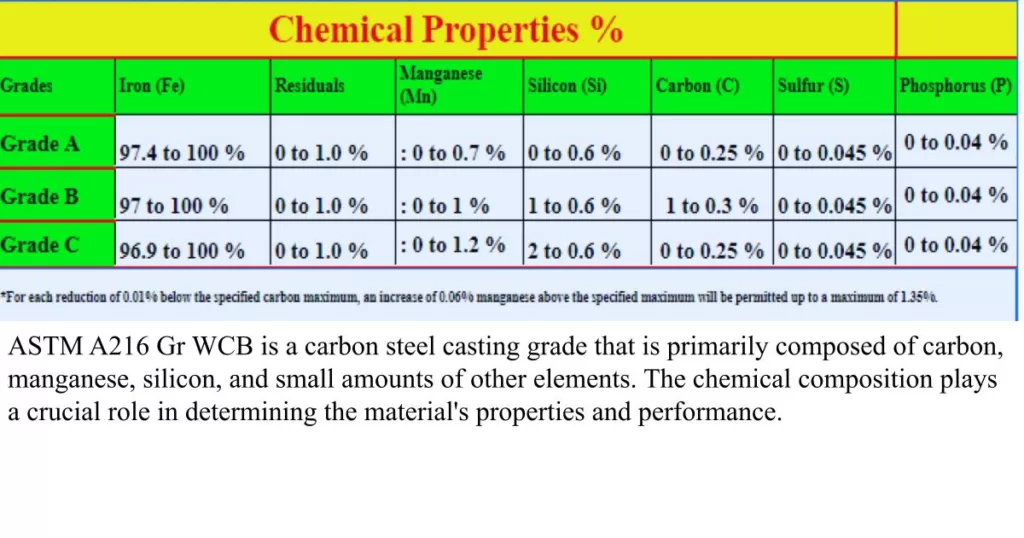

ASTM A216 Gr WCB is a carbon steel casting grade that is primarily composed of carbon, manganese, silicon, and small amounts of other elements. The chemical composition plays a crucial role in determining the material’s properties and performance. With a maximum carbon content of 0.30%, ASTM A216 Gr WCB offers excellent weldability and machinability, making it suitable for a wide range of applications. The manganese content improves the material’s harden ability, while silicon enhances its strength and impact resistance. Additionally, ASTM A216 Gr WCB exhibits good corrosion resistance, even in harsh environments. These properties make it an ideal choice for applications that require strength, durability, and resistance to corrosion.

Applications of ASTM A216 Gr WCB

ASTM A216 Gr WCB finds extensive use in various industries due to its exceptional properties. One of the primary applications of ASTM A216 Gr WCB is in the oil and gas industry. It is commonly used for valves, flanges, and fittings in pipelines and refineries. The material’s corrosion resistance and strength make it suitable for handling various fluids and gases under high-pressure and high-temperature conditions. In the petrochemical industry, ASTM A216 Gr WCB is utilized for pumps, compressors, and other equipment that require resistance to corrosive chemicals. The power generation industry also relies on ASTM A216 Gr WCB for turbine components, boiler parts, and steam valves, where the material’s high strength and ability to withstand elevated temperatures are crucial. Other applications include construction, mining, and general engineering, where ASTM A216 Gr WCB is used for structural components and machinery.

Manufacturing Process of ASTM A216 Gr WCB

The manufacturing process of ASTM A216 Gr WCB involves several steps to ensure the material’s quality and consistency. The process starts with the selection of high-quality raw materials, including scrap steel and pig iron, which are melted in an electric arc furnace. The molten metal is then poured into molds to form the desired shape. The casting process allows for complex shapes and intricate details, making ASTM A216 Gr WCB suitable for various applications. After solidification, the castings undergo heat treatment to enhance their mechanical properties. This involves heating the castings to a specific temperature and then cooling them at a controlled rate. The heat treatment process improves the material’s hardness, strength, and toughness, ensuring it meets the required specifications. The final step involves machining and finishing the castings to achieve the desired dimensions and surface finish.

Advantages and Disadvantages of ASTM A216 Gr WCB

ASTM A216 Gr WCB offers several advantages that make it a preferred choice for many industrial applications. Its excellent strength, durability, and corrosion resistance make it suitable for demanding environments. The material’s weldability and machinability allow for ease of fabrication and installation. ASTM A216 Gr WCB also exhibits good heat resistance, making it suitable for high-temperature applications. However, like any material, ASTM A216 Gr WCB has its limitations. It is not recommended for applications involving exposure to sulfuric acid or other highly corrosive chemicals. Additionally, the material can be prone to cracking if not properly heat treated. It is important to consider these factors and consult with experts when selecting ASTM A216 Gr WCB for your specific project.

Comparison with other grades of cast carbon steel

When choosing a cast carbon steel grade, it’s essential to consider the specific requirements of your application. ASTM A216 Gr WCB is just one of many options available, and each grade has its unique properties and advantages. One commonly compared grade is ASTM A216 Gr WCC, which has a slightly lower carbon content. While ASTM A216 Gr WCB offers better weldability and machinability, ASTM A216 Gr WCC provides improved impact resistance and toughness. Another grade to consider is ASTM A216 Gr LCC, which contains a higher carbon content and offers better heat resistance. Ultimately, the choice between these grades depends on the specific demands of your project, and consulting with materials experts can help you make an informed decision.

Common uses and industries that utilize ASTM A216 Gr WCB

ASTM A216 Gr WCB finds widespread use in various industries that require a combination of strength, durability, and corrosion resistance. In the oil and gas industry, it is used for valves, flanges, and fittings in pipelines and refineries. The petrochemical industry utilizes ASTM A216 Gr WCB for pumps, compressors, and chemical handling equipment. In the power generation sector, it is used for turbine components, boiler parts, and steam valves. Other industries that utilize ASTM A216 Gr WCB include construction, mining, and general engineering, where it is used for structural components and machinery. The versatility and reliability of ASTM A216 Gr WCB make it an excellent choice for a wide range of applications.

Maintenance and care for ASTM A216 Gr WCB

To ensure the longevity and performance of ASTM A216 Gr WCB, proper maintenance and care are essential. Regular inspection and cleaning are necessary to remove any dirt, debris, or corrosive substances that may accumulate on the surface. For applications involving exposure to corrosive environments, applying protective coatings can help enhance the material’s resistance to corrosion. It is important to follow the manufacturer’s guidelines for maintenance and consult with experts to determine the best practices for your specific application. By implementing proper maintenance measures, you can maximize the lifespan and performance of ASTM A216 Gr WCB in your project.

How to choose the right ASTM A216 Gr WCB for your project

Choosing the right ASTM A216 Gr WCB for your project requires careful consideration of various factors. Start by identifying the specific requirements of your application, such as the operating conditions, temperature, and exposure to corrosive substances. Consulting with materials experts can help you determine the appropriate grade and specifications for your project. Additionally, it is crucial to ensure that the ASTM A216 Gr WCB you select meets the relevant industry standards and certifications. Working with reputable suppliers and manufacturers can provide you with the assurance of quality and reliability. By taking these steps and making informed decisions, you can choose the right ASTM A216 Gr WCB that will meet the demands of your project.

Conclusion and final thoughts

In conclusion, ASTM A216 Gr WCB is a versatile and reliable carbon steel casting grade that offers exceptional strength, durability, and corrosion resistance. Its properties make it suitable for various industries, including oil and gas, petrochemical, power generation, and more. Understanding the chemical composition, mechanical properties, and manufacturing process of ASTM A216 Gr WCB is crucial when selecting the material for your project. By considering its advantages, disadvantages, and comparing it with other grades, you can make an informed decision. Whether you’re an engineer, project manager, or simply interested in materials, this comprehensive guide has provided you with valuable insights and practical knowledge on ASTM A216 Gr WCB. Now, armed with this information, you can confidently choose ASTM A216 Gr WCB for your next industrial project and ensure its success.